Operators Manual

27

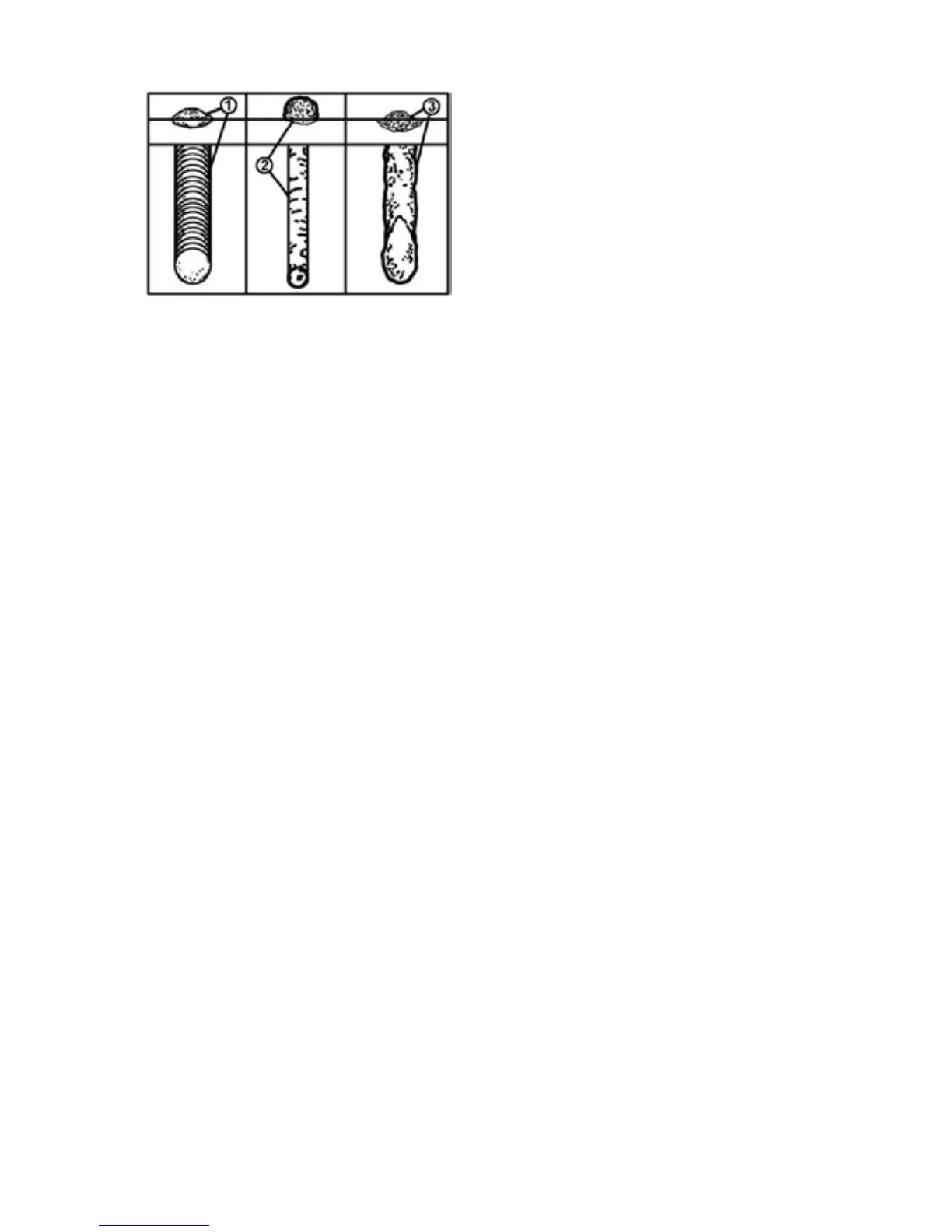

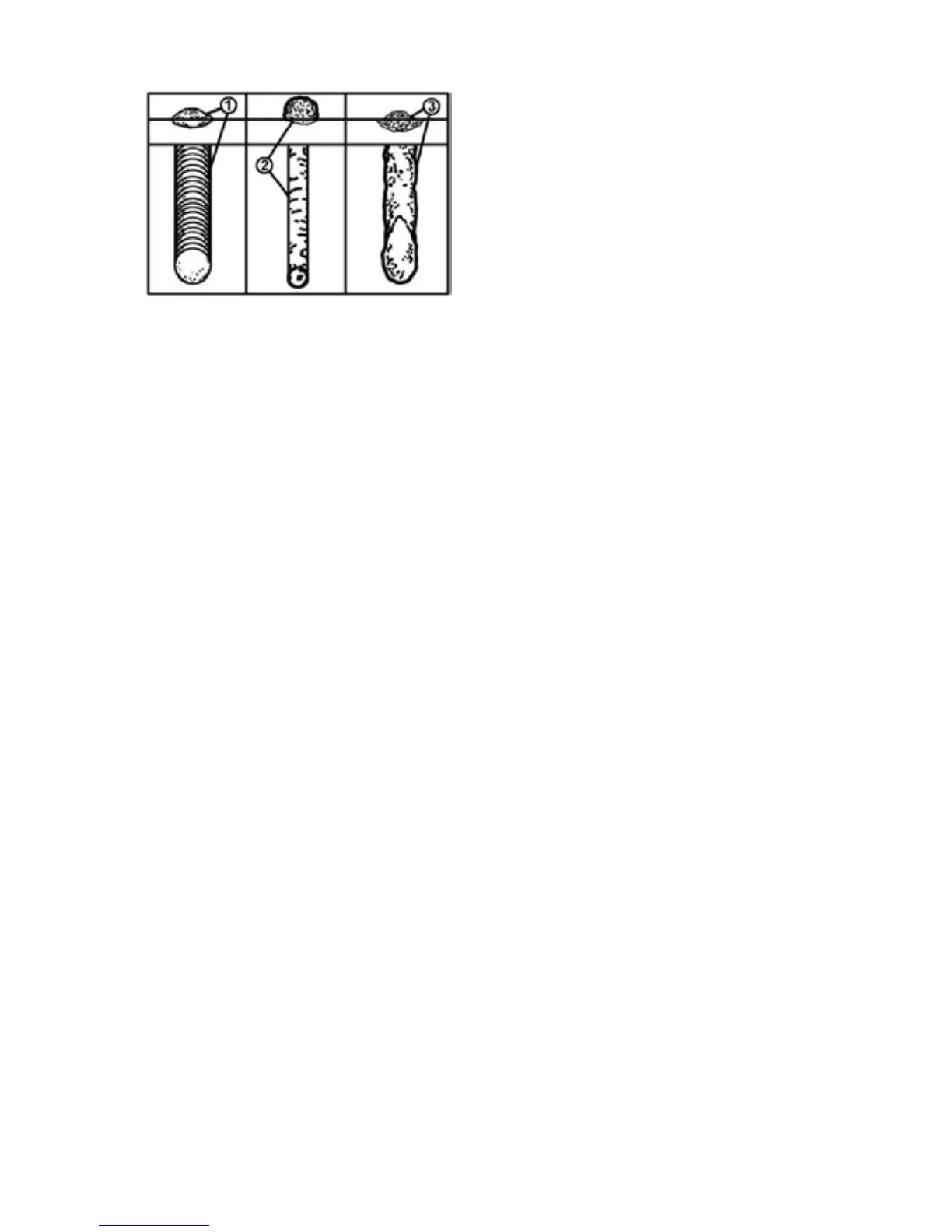

1. When proper rod is used:

• The bead will lay smoothly over the work without ragged edges

• The base metal puddle will be as deep as the bead that rises above it

• The welding operaon will make a crackling sound similar to the sound of eggs frying

2. When a rod too small is used

• The bead will be high and irregular

• The arc will be dicult to maintain

3. When the rod is too large

• The arc will burn through light metals

• The bead will undercut the work

• The bead will be at and porous

• Rod may freeze or sck to work piece

Note: Rate of travel over the work also aects the weld. To ensure proper penetraon and

enough deposit of rod, the arc must be moved slowly and evenly along the weld seam.

Operaon

1. Seng the Amperage Control

The welder has an innite output current control. It is capable of welding with 2.0mm and

2.6mm and 3.2mm electrodes.

There is no golden rule that determines the exact amperage required for every situaon.

It is best to pracce your welds on scrap metal which matches the metals you intend to

work with to determine correct seng for your job. The electrode type and the thickness

of the work piece metal determine the amount of heat needed in the welding process.

Heavier and thicker metals require more voltage (amperage), whereas lighter and thinner

metals require less voltage (amperage).

Loading...

Loading...