OM-626 Page 12

4-3. Coolant Guidelines

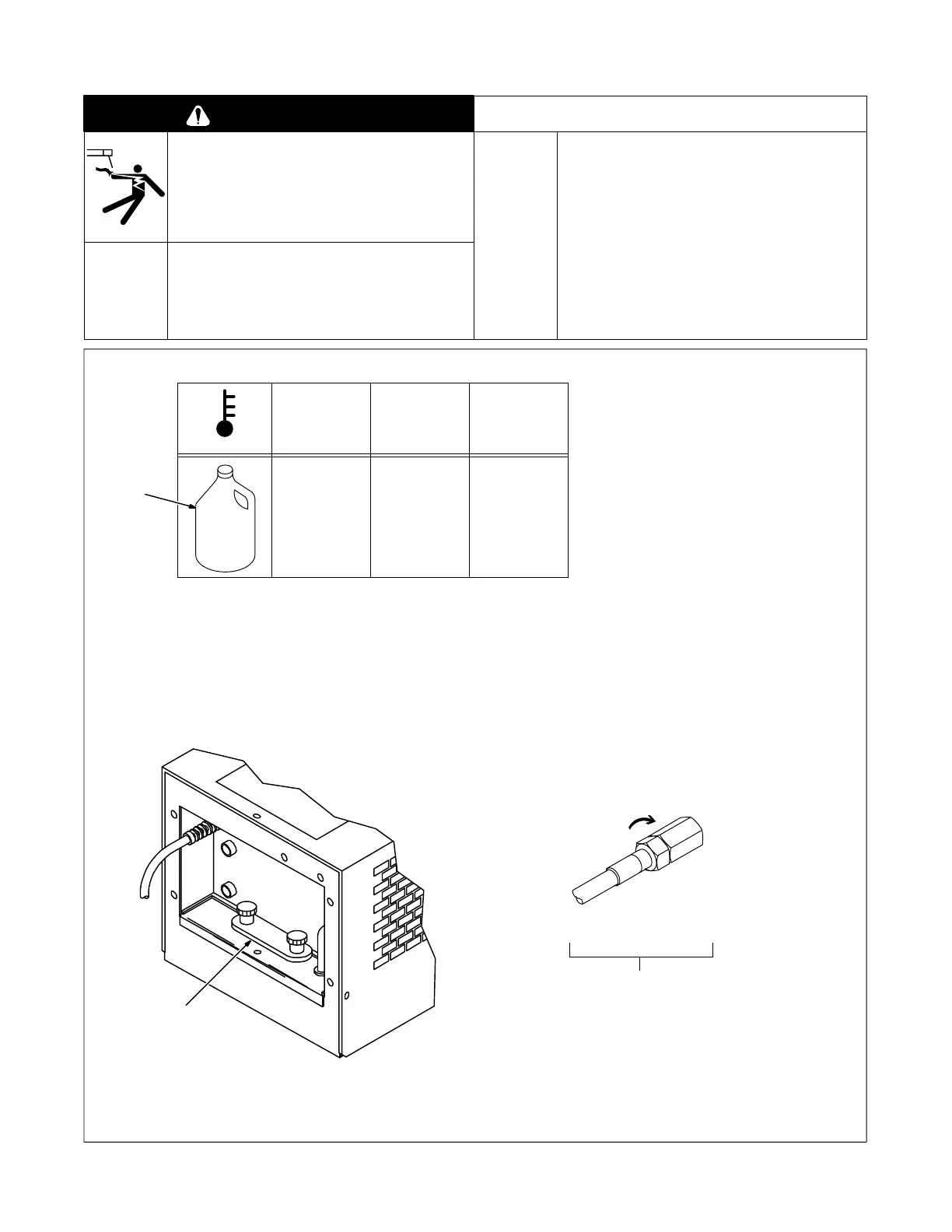

WARNING

ELECTRIC SHOCK can kill; MOVING

PARTS can cause serious injury.

• Do not touch live electrical parts.

• Keep away from moving parts.

• Disconnect input power plug from receptacle before

cleaning system components.

FAILURE TO PROPERLY MAINTAIN

COOLANT SYSTEM can cause damage

to the coolant system and torch/gun.

• Circulate and flush clear water through entire

system, and replace coolant every six months.

INCORRECT COOLANT will damage

unit.

• Use plain distilled or deionized water, or use high

quality tap water.

• In freezing temperatures use only a mix of pure

ethylene glycol and distilled or deionized water such

as MILLER coolant Part No. 128 705 or equivalent.

DO NOT USE AUTOMOTIVE ANTIFREEZE.

Ref. ST-137 225-D / S-0760

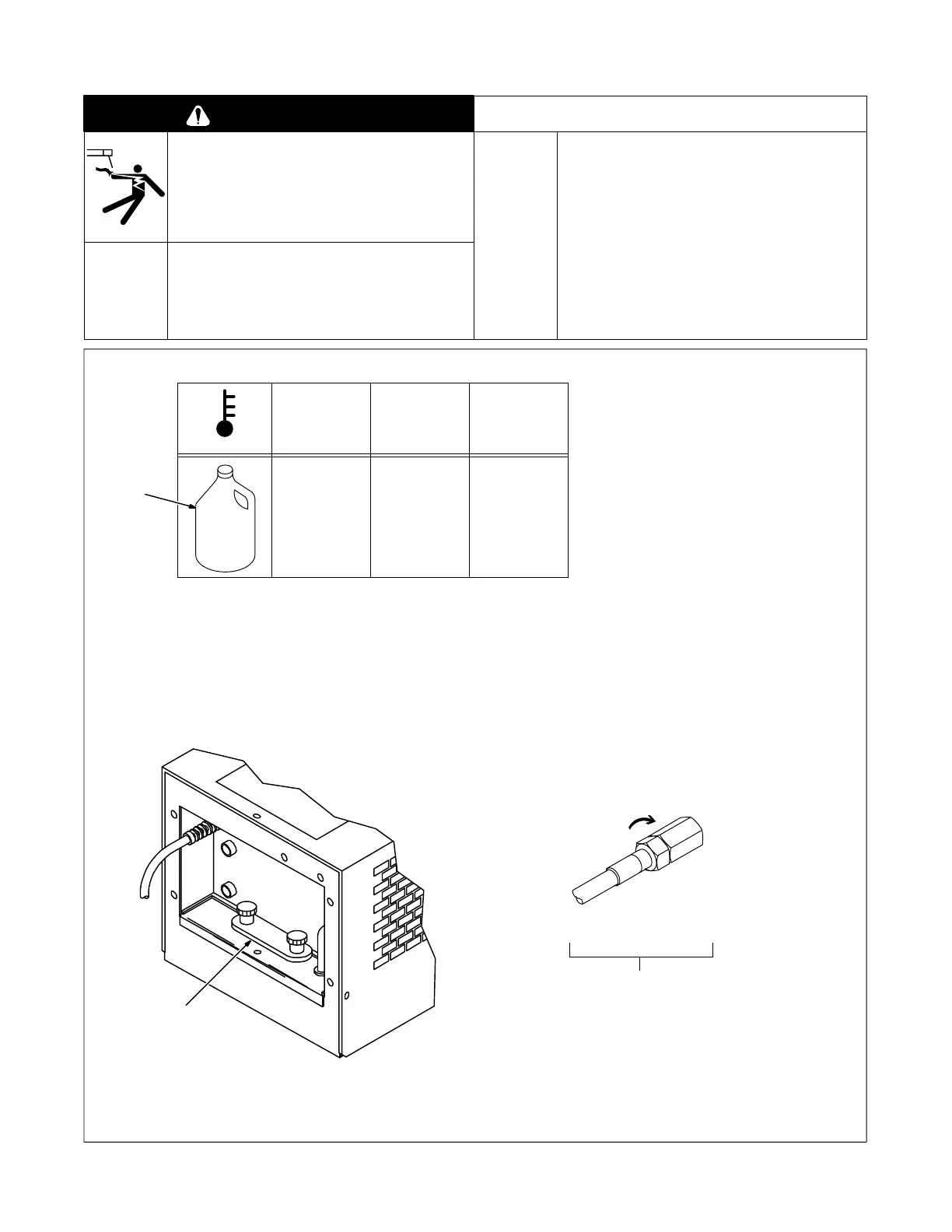

Follow these guidelines to de-

crease corrosion in unit.

Material in contact with coolant can

only be brass, copper, silver solder,

300 Series stainless steel, or plas-

tic.

1 Coolant

See table for coolant mixture need-

ed for operating temperature.

2 Filler Cover

Keep coolant level full. Length of

coolant hoses affects amount of

coolant needed in unit.

Change coolant when dirty or every

6 months.

3 Connections

Keep connections tight. Make elec-

trical connections with connectors

of the same metal.

1

Coolant

Tighten Connections

3

TEMP.

Above 32° F

(0° C)

0° F (–18° C)

to 32° F (0°C)

Below 0° F

(–18° C)

Distilled,

Deionized,

Or High

Quality Tap

Water

35% Ethylene

Glycol And

65% Water

See Ethylene

Glycol

Manufacturer’s

Suggestion

2

Figure 4-4. Coolant Guidelines

Loading...

Loading...