OM-626 Page 14

4-6. Operating Coolant System

PLUGGED OR CLOGGED LINES OR HOSES can cause cooling system damage.

• Do not operate coolant system with plugged or clogged lines or hoses.

CAUTION

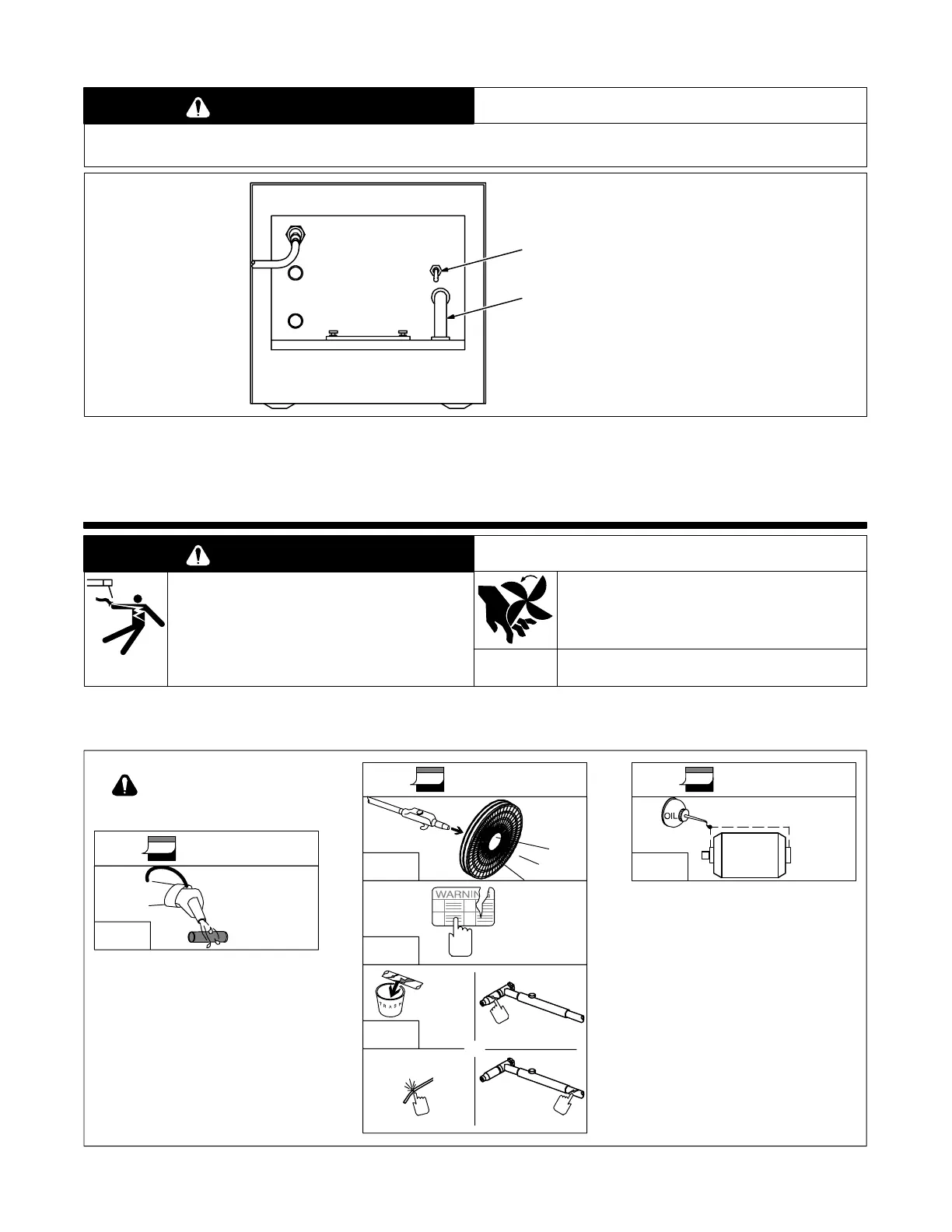

Ref. ST-137 226-C

1 Power Switch

Use switch to turn unit On and Off.

2 Flow Indicator

Use indicator to check coolant

pump operation. Coolant should

flow through indicator when Power

switch is On.

If hoses are clogged, turn Off unit to

prevent damage to coolant system.

Do not operate unit until hoses are

cleared (see Sections 5-2 and 5-4).

1

2

Figure 4-7. Operating Coolant System

SECTION 5 – MAINTENANCE & TROUBLESHOOTING

WARNING

ELECTRIC SHOCK can kill.

• Do not touch live electrical parts.

• Turn Off unit and disconnect input power plug from

receptacle before inspecting, maintaining, or

servicing.

MOVING PARTS can cause injury.

• Keep away from moving parts.

Maintenance to be performed only by qualified persons.

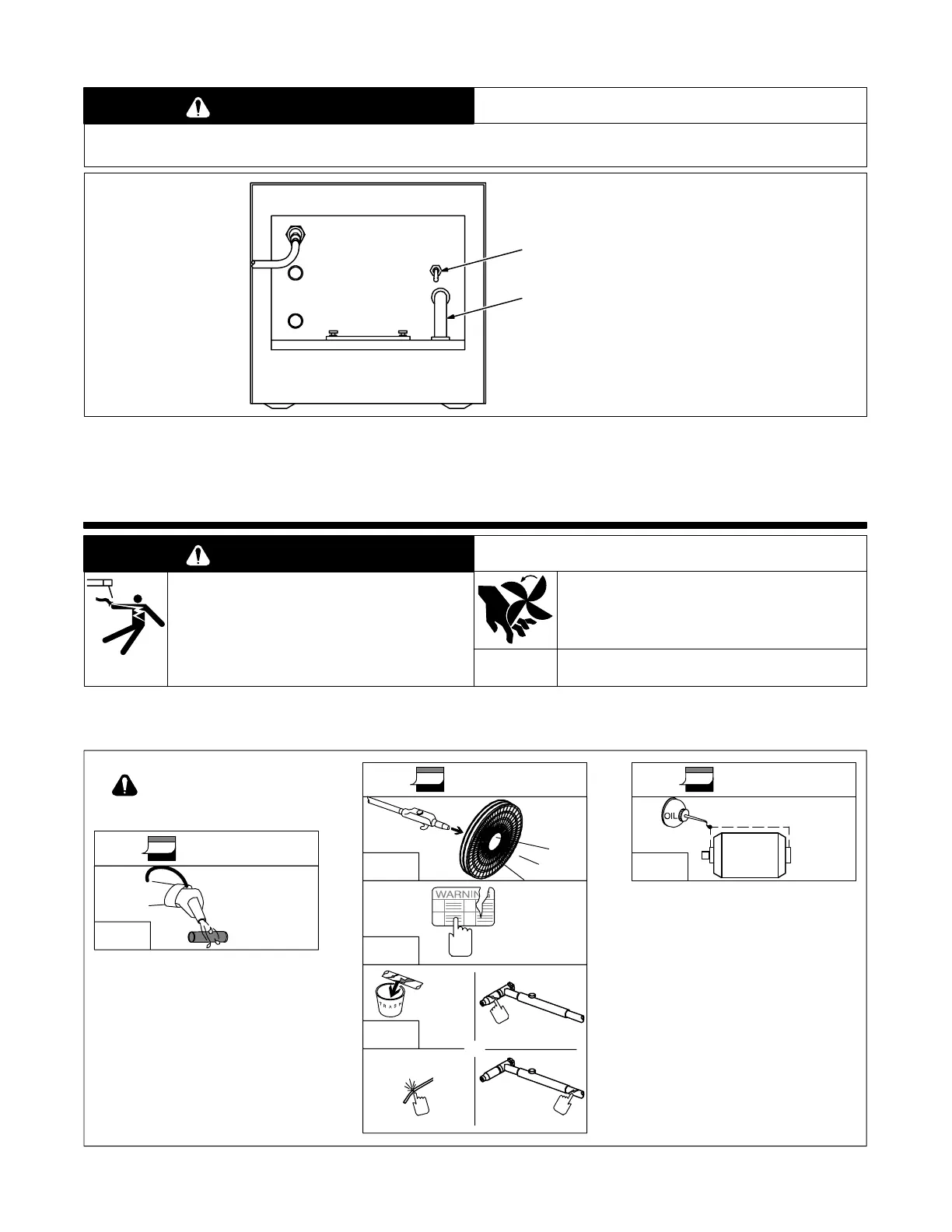

5-1. Routine Maintenance

1 Month

Clean

Coolant

Strainer

5-2

Turn Off all power before

maintaining.

6 Months 12 Months

Blow

Out

Fins

– –

Replace

Unreadable

Labels

6

Gun/Torch Body

Water/Gas Hose Gun/Torch Cable

– –

Replace

Cracked

Parts

Oil

Motor

5-3

Figure 5-1. Maintenance Schedule

Loading...

Loading...