OM-626 Page 16

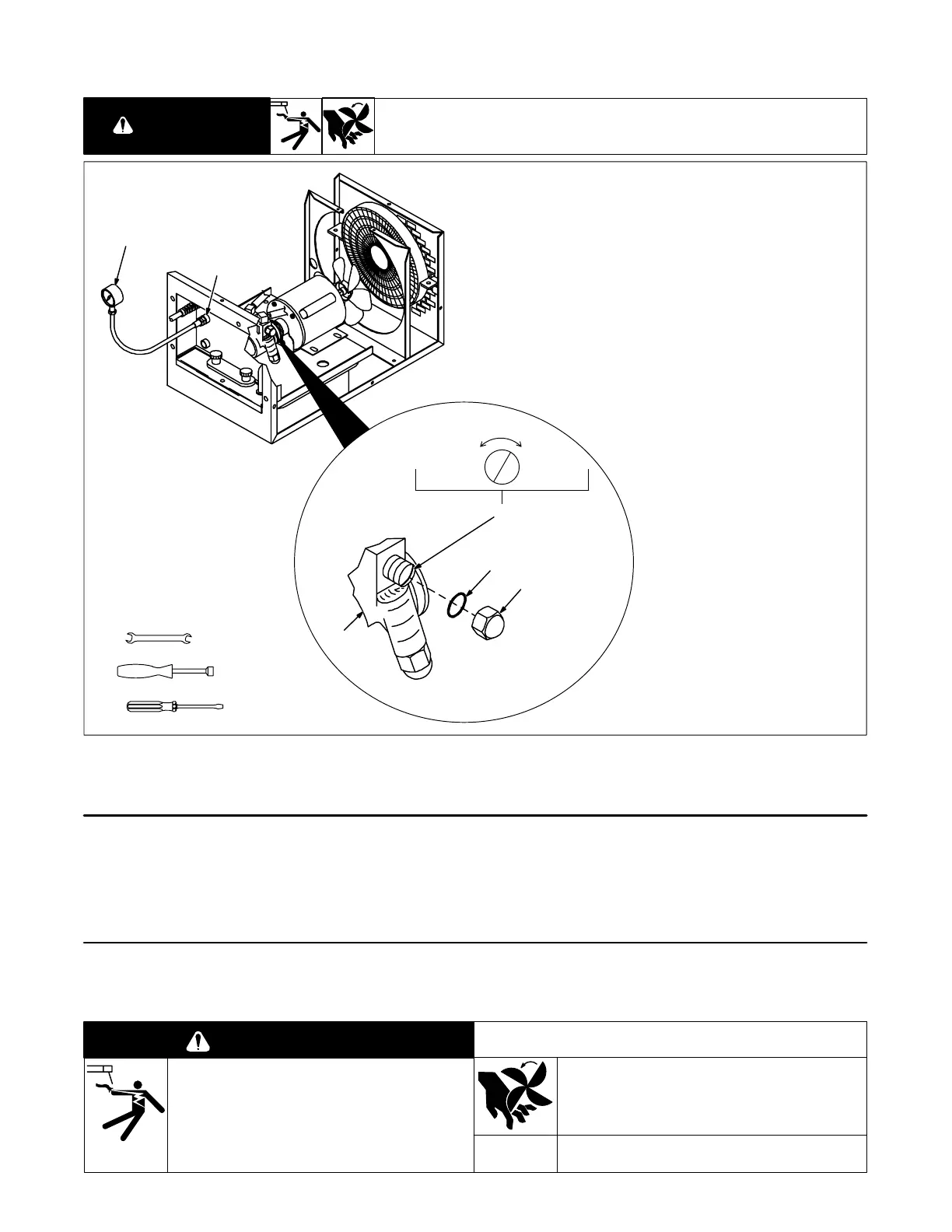

5-4. Adjusting Relief Valve

READ SAFETY BLOCKS at start of

Section 5 before proceeding.

WARNING

Ref. ST-159 334 / Ref. ST-159 301

If hoses become clogged, the relief

valve protects the unit for less than

two minutes by returning coolant

back to the pump.

Relief valve is factory set to open at

60 psi (414 kPa). Adjust relief valve

only if pump is replaced. To adjust,

obtain pressure gauge and proceed

as follows:

Turn Off and unplug unit.

1 Coolant Out Fitting

2 Pressure Gauge

Connect gauge to Coolant Out fitting.

Block or plug any output fitting on

gauge.

3 Coolant Pump

4 Acorn Nut

5 Washer

6 Relief Valve Adjustment Screw

Plug in and turn On unit.

Set pressure to required level. Do not

set pressure above torch/gun man-

ufacturer’s recommended maximum

pressure rating.

Turn Off and unplug unit.

Disconnect gauge, and reinstall

parts. Reinstall wrapper.

Tools Needed:

3/4 in

1

2

3

4

5

6

IncreaseDecrease

3/8 in

Figure 5-4. Adjusting Relief Valve

5-5. Thermal Protection

A bimetallic strip protects the unit from damage due to overheating. If motor gets too hot, the motor stops. When the

motor cools down, it will start running.

5-6. Troubleshooting

WARNING

ELECTRIC SHOCK can kill.

• Do not touch live electrical parts.

• Turn Off unit and disconnect input power plug from

receptacle before inspecting, maintaining, or

servicing.

MOVING PARTS can cause injury.

• Keep away from moving parts.

Maintenance to be performed only by qualified persons.

Loading...

Loading...