OM-626 Page 13

4-4. Connecting Coolant Hoses

CAUTION

INCORRECT HOSES will damage unit.

• Use hoses compatible with coolant such as Neoprene, Buna-N, Hypalon, or equivalent.

• Incorrect hoses will degrade and plug or damage the coolant system.

OVERHEATING Gas Tungsten Arc Welding (GTAW) torches and Gas Metal Arc Welding (GMAW) guns can

damage torches and guns.

• If using a water-cooled torch/gun and recirculating system, do not make connections from the coolant system to a water valve; instead, make

connection directly from the coolant system to torch/gun hoses.

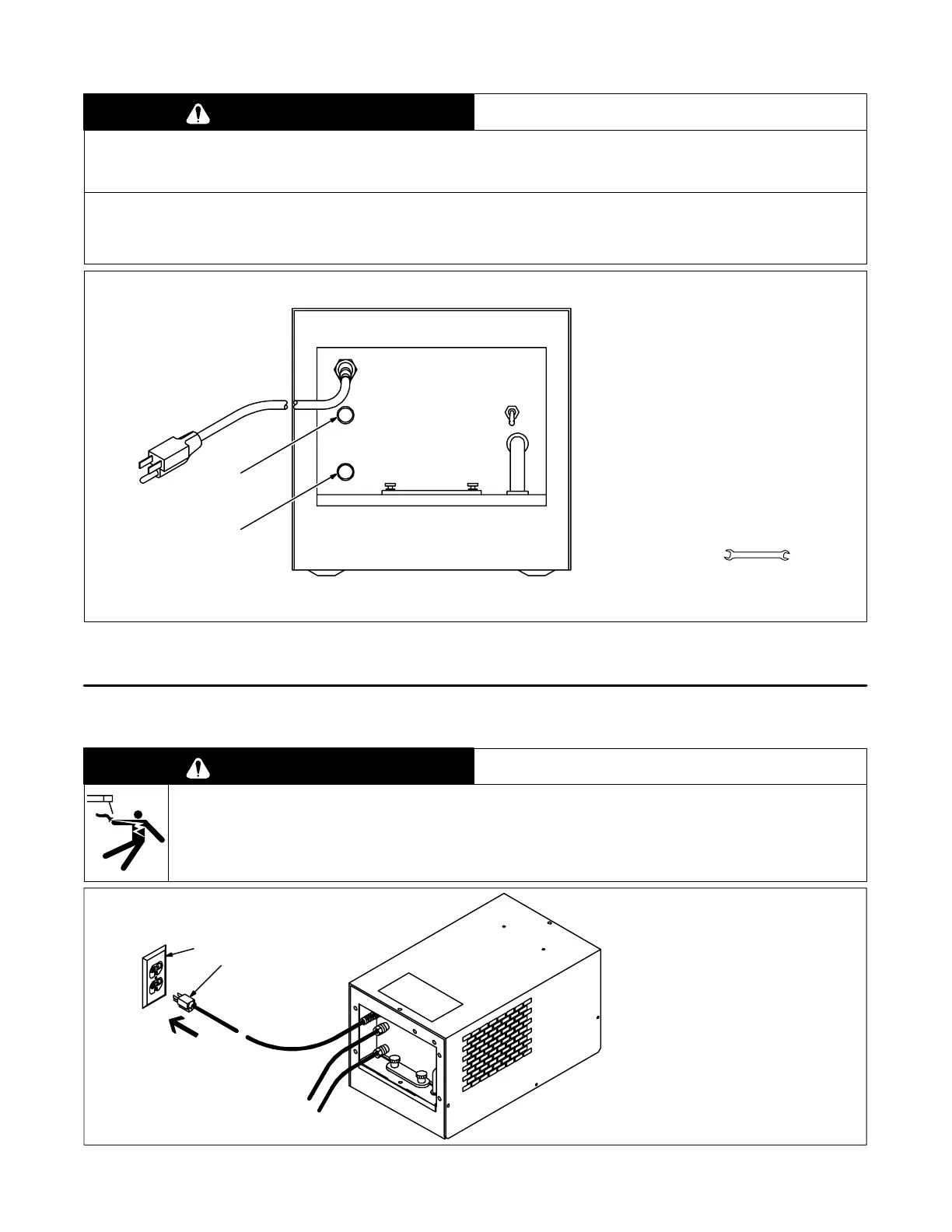

Ref. ST-137 226-C / Ref. ST-153 246

Obtain two coolant hoses with

proper fittings. Fittings have 5/8-18

left-hand threads. Use high quality

hoses without carbon or steel rein-

forcing. To decrease corrosion, use

fittings made of materials listed in

Figure 4-4.

1 Coolant Out Fitting

2 Coolant In Fitting

See Section 4-1 for typical hose

connections.

Tools Needed:

5/8 in

1

2

Figure 4-5. Connecting Coolant Hoses

4-5. Connecting Input Power

WARNING

ELECTRIC SHOCK can kill.

• Do not touch live electrical parts.

• Do not attempt to get 115 volts ac from the 230 volts input terminals on the welding power source.

• If 115 or 230 volts ac is not available, use an auxiliary power supply.

• Connect power cord to a proper receptacle.

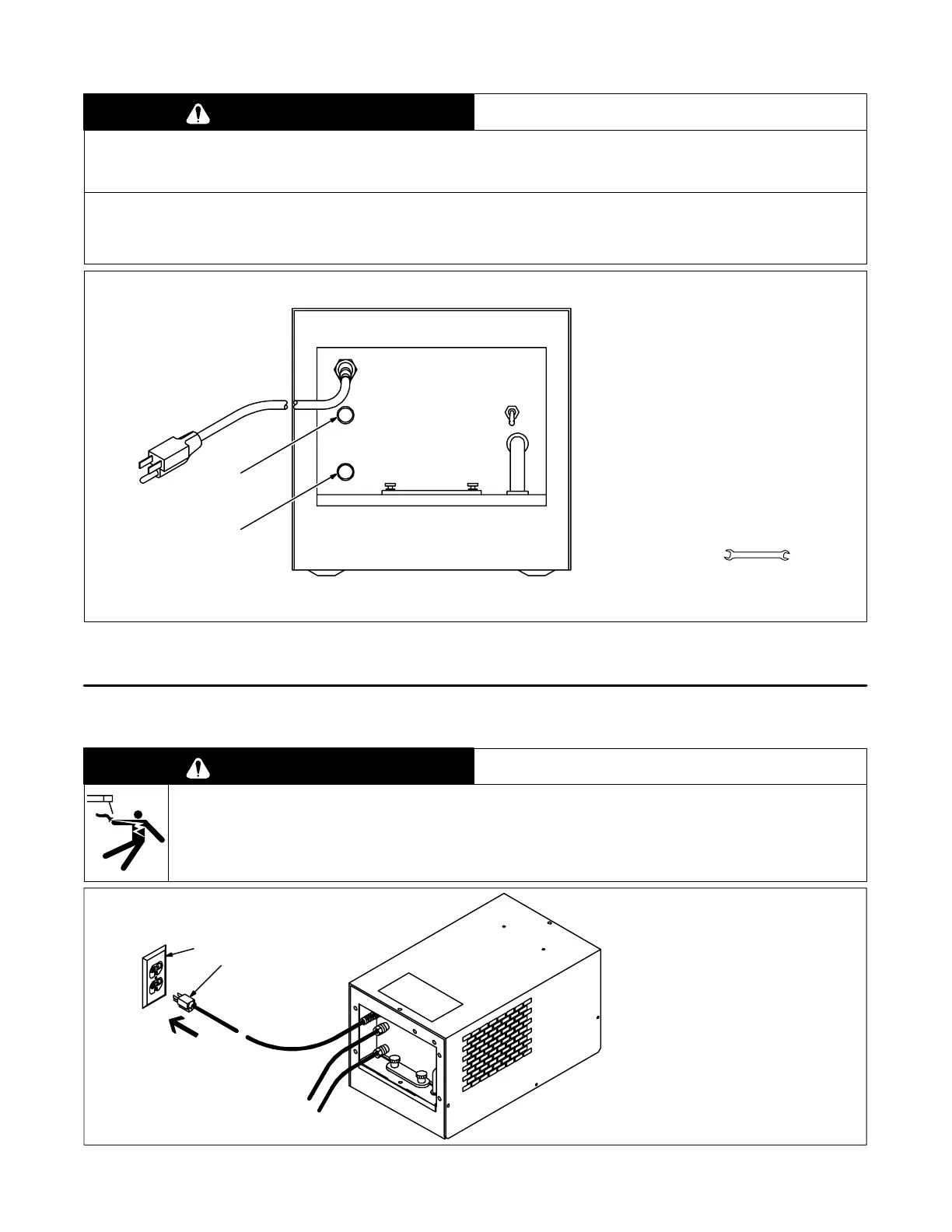

ST-159 385

1 Grounded Receptacle

2 Input Power Cord And Plug

PLG1

Connect input power plug to a prop-

er receptacle.

1

2

Figure 4-6. Input Power Connections

Loading...

Loading...