Do you have a question about the Miller AUTO ARC TIG 50A and is the answer not in the manual?

Details amendments for the installation section.

Details amendments for the parts list.

Overview of safety practices and their importance.

General safety guidelines applicable to welding and cutting operations.

Safety precautions specific to arc welding processes.

Index of relevant safety standards and their sources.

Explanation of duty cycle and its impact on equipment operation.

Interpreting the volt-ampere curve for output characteristics.

Key information and safety guidelines for the unit.

Guidelines for receiving and handling the welding power source.

Detailed description of the welding power source.

General information for proper installation and certification.

Further details on certification for FCC compliance.

Requirements for connecting power service to HF equipment.

Information related to the welding machine itself.

Proper installation procedures for welding leads.

Guidelines for wiring near the welding area to minimize interference.

Proper grounding methods for HF equipment.

Considerations for installing in a metal building.

Procedure for certifying individual installations.

Checklist for verifying proper installation.

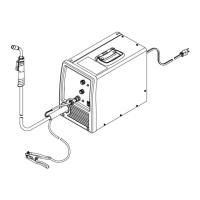

Step-by-step procedure for Gas Tungsten-Arc Welding.

Procedure for safely shutting down the welding equipment.

Instructions for cleaning internal components of the unit.

Information on inspecting and adjusting spark gaps.

Detailed procedure for adjusting spark gaps for optimal performance.

Explanation of overload protection mechanisms like fuses.

Guide to diagnose and remedy common equipment problems.

Guidelines for selecting a suitable installation location for the unit.

Instructions for connecting the torch and work terminals.

Procedures for making electrical input connections to the unit.

Operation of the main power switch.

Function and indication of the pilot light.

Details on the remote control receptacle and contactor switch.

Details on the remote control receptacle and current control switch.

Adjusting coarse and fine weld current controls.

Using meters to monitor welding operation.

Operation of the high frequency switch.

Adjusting the high-frequency intensity for arc initiation.

Controlling the post-flow gas time after welding.

Operation of the remote hand switch.

Using the optional remote hand control for current adjustment.

Using the optional remote foot control for current and contactor.

Controlling the pre-flow gas and coolant time.

Controlling weld time for spot welding operations.

Exploded view and list of parts for the main assembly.

List of parts for the rectifier, silicon diode assembly.

List of parts for the HF panel assembly.

List of parts for the front panel and its components.

List of parts for the control panel and its components.

List of components for the control circuit card.

List of parts for optional equipment such as timers and controls.

| Brand | Miller |

|---|---|

| Model | AUTO ARC TIG 50A |

| Category | Welding System |

| Language | English |