How to troubleshoot high output at generator power AC receptacles on a Miller Welding System?

- FFrancis RiceSep 7, 2025

Have a Factory Authorized Service Agent adjust generator power field current resistor R3.

How to troubleshoot high output at generator power AC receptacles on a Miller Welding System?

Have a Factory Authorized Service Agent adjust generator power field current resistor R3.

How to troubleshoot low open-circuit voltage on a Miller Welding System?

Check the position of the Process/Contactor switch.

How to troubleshoot no remote fine amperage or voltage control on a Miller Welding System?

To troubleshoot no remote fine amperage or voltage control: * Check and secure connections to the Remote receptacle. * Repair or replace the remote control device. * Have a Factory Authorized Service Agent check current sensing devices, and connections.

What causes low output at generator power AC receptacles on a Miller Welding System?

To troubleshoot low output at the generator power AC receptacles: * Check fuse F1, and replace if open. Have a Factory Authorized Service Agent check integrated rectifier SR2, resistor R3, and capacitor C6. * Have a Factory Authorized Service Agent check brushes and slip rings.

| Max Output | 500 A |

|---|---|

| Fuel Capacity | 25 gal (94.6 L) |

| Fuel Tank Capacity | 25 gal (94.6 L) |

| Generator Output | 12, 000 Watts |

| Generator Power | 12 kW |

| Engine | Kubota D1803 |

| Open Circuit Voltage | 80 V |

| Welding Processes | Stick (SMAW), TIG (GTAW), MIG (GMAW), Flux-Cored (FCAW) |

Explains warning symbols and hazard indicators used throughout the manual.

Covers dangers like electric shock, fumes, arc rays, fire, and noise.

Details risks associated with the engine, including battery, fuel, and moving parts.

Outlines dangers related to compressed air systems and equipment.

Covers various hazards like fire, falling equipment, overheating, and battery issues.

Warns about chemicals exposure from product use and diesel exhaust.

Explains electromagnetic field effects and precautions for electronic equipment and medical implants.

Provides definitions and explanations for various safety symbols used in the manual.

Guides users to find the product's serial number and rating information.

Details the welding output, power ratings, and engine specifications of the equipment.

Lists the physical dimensions, weight, and operational angle limitations of the unit.

Specifies the IP rating and temperature ranges for operation and storage.

Explains the unit's duty cycle and the risks of overheating, with performance curves.

Presents a graph illustrating typical fuel consumption under various load conditions.

Shows the voltage and amperage output capabilities for different welding modes.

Displays the voltage and amperage output capabilities for various welding modes.

Illustrates the generator's AC power output capabilities in amperes.

Provides instructions for mounting and securing the welder/generator unit.

Details the procedure for properly grounding the generator frame to a vehicle.

Guides the installation of the exhaust pipe for proper ventilation.

Explains the correct procedure for connecting the unit's battery.

Outlines essential checks to perform before starting the engine for safe operation.

Identifies the weld output terminals and their connections for different welding processes.

Provides a guide for selecting appropriate weld cable sizes based on current and length.

Explains how to connect remote controls and accessories to the unit's receptacle.

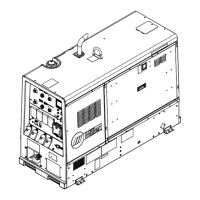

Identifies the location and purpose of the main controls on the front panel.

Provides a detailed explanation of each front panel control and indicator light.

Details the engine start switch, speed selection, and engine display functions.

Explains the remote control receptacle, process/contactor switch, and adjust controls.

Describes the function of various indicator lights like Setup, In Use, and Arc Control.

Guides the user through the correct procedure for starting the engine.

Explains how to select welding processes and control output using the switch.

Describes how to access and navigate the service menu for settings adjustments.

Details how to adjust arc control settings for different welding processes to optimize performance.

Explains how to adjust dynamic dig settings to control arc characteristics and penetration.

Explains the Lift-Arc TIG process, including auto-stop and auto-crater functions.

Details how to use remote controls to adjust voltage and amperage for CC and CV welding.

Explains how to use the engine block heater to maintain optimal engine temperature in cold weather.

Provides step-by-step instructions for updating the unit's software via USB.

Identifies the different generator power receptacles and their capacities.

Explains GFCI protection, how to reset, and procedures for testing GFCI receptacles.

Directs users to the maintenance label for service information.

Provides instructions for cleaning the exterior of the unit to prevent rust.

Outlines scheduled maintenance tasks based on operating hours.

Details the procedure for cleaning or replacing the air cleaner element.

Guides the user through the process of replacing the unit's battery.

Lists recommended engine oil types and viscosity grades for various temperatures.

Covers procedures for changing oil, filters, and servicing the fuel system.

Explains how to drain water from the fuel water separator to prevent engine damage.

Identifies supplementary protectors, circuit breakers, and fuses for overload protection.

Lists common error displays and their meanings for troubleshooting.

Provides a troubleshooting guide for common welding and generator power issues.

Troubleshooting specific to welding output problems.

Troubleshooting issues related to standard generator power output.

Troubleshooting common engine-related problems and failures.

Lists recommended spare parts for maintenance and replacement.

Describes the layout and controls of the engine information display.

Explains the service reminder display and its function.

Describes the RPM signal failed display and how to reset it.

Shows different display screens and how to navigate between them.

Details the low fuel and no fuel warning indicators on the display.

Explains how warnings and shutdowns are displayed and acknowledged.

Guides the user on how to access the main menu using passwords.

Outlines the available options within the main menu for settings and service.

Explains what wetstacking is and how to prevent it.

Details the procedure for running in the engine using load banks or resistance grids.

Provides guidance on selecting appropriate auxiliary equipment and plugs.

Explains the process of grounding the generator frame to a vehicle for safety.

Details how to properly ground the generator when connecting it to building electrical systems.

Explains how to calculate the power requirements for various types of equipment.

Explains how to calculate the starting power requirements for motors.

Illustrates typical connections for using the generator as standby power.

Offers guidance on selecting appropriate extension cords based on voltage, current, and length.

Outlines the terms and conditions of the limited warranty provided by Miller.

Provides contact information for warranty inquiries and local distributor support.

Offers guidance on contacting distributors or service agencies for support.