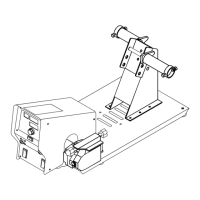

How to troubleshoot Miller D-74DX Welding System when wire feeds but is not energized?

- DDerek WilliamsJul 30, 2025

If the wire feeds and shielding gas flows, but the electrode wire is not energized in your Miller Welding System, check the interconnecting cord connections. If the connections are secure, check the cord for continuity and repair or replace it.