16

Pellerin Milnor Corporation

3.1.1.1 Guards and Related Components

BNUUUH01.R09 0000399322 A.5 A.26 A.9 11/4/21 11:27 AM Released

Examine these items. If an item is damaged, missing, or has the wrong setting, correct this

discrepancy immediately to prevent injury.

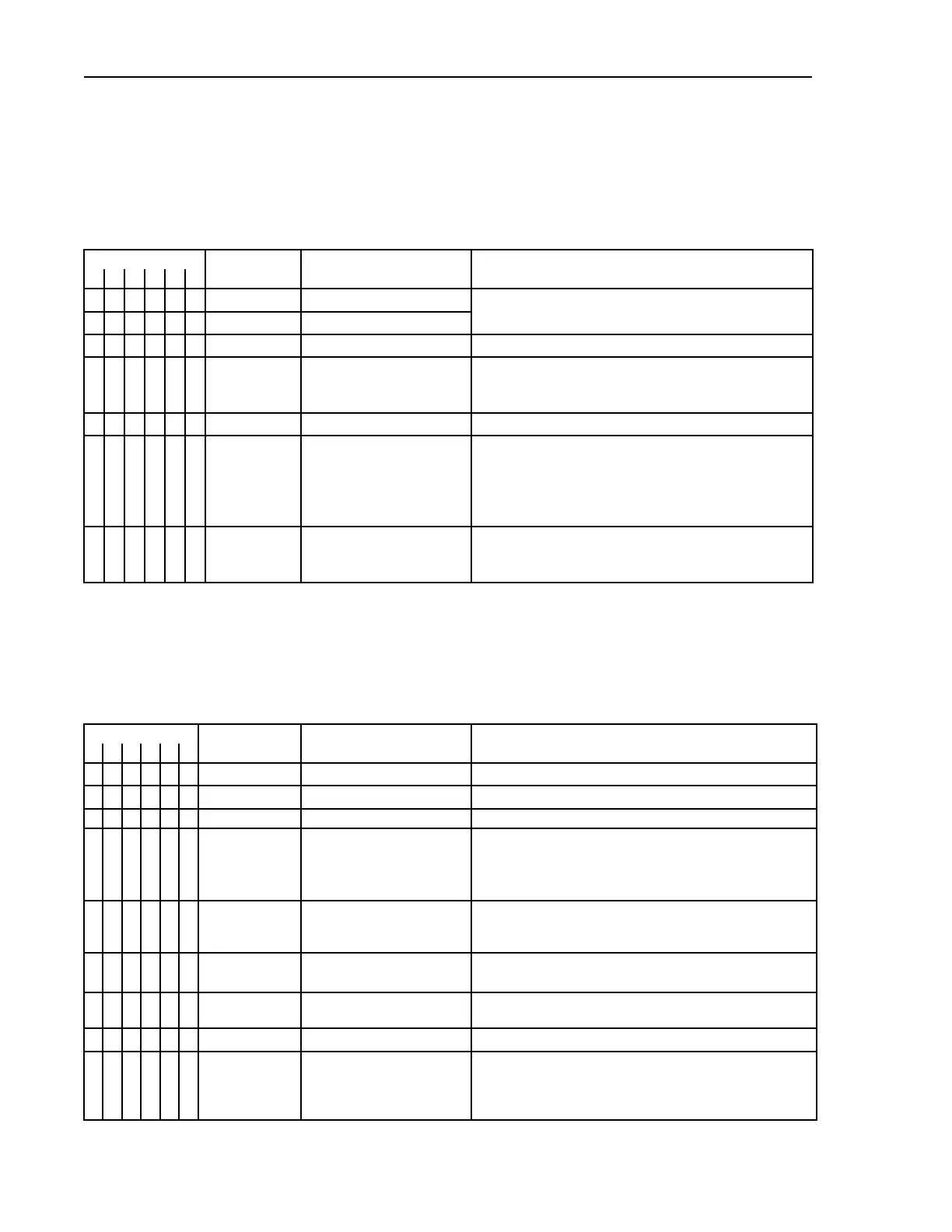

Table 1. Guards and Related Components

Mark

Do this each

Component

More Data

1 2

3

4

5

6

x

day* guards, covers Speak to your dealer or Milnor for replacement

components.

x

day* safety placards

x

200 hours fasteners Fasteners must be tight.

x

day* safety stands, bars or pins

(painted red)

Speak to your dealer or Milnor for replacement compo-

nents. See the section “Use the Red Safety Supports for

Maintenance...” in the Safety chapter.

x

200 hours anchor bolts and grout Grout must be good. Bolts must be tight.

x

day* door interlock If the machine operates with the door open:

• Immediately remove power.

• Do not permit operation.

• Speak to your dealer or Milnor.

x

day* emergency stop button

(optional on some washer-

extractors)

See Section 3.2.7 , page 32. Do a test of the control.

3.1.1.2 Filters, Screens, and Sensitive Components

BNUUUH01.R10 0000399352 A.5 A.26 A.19 11/16/21 10:29 AM Released

Remove contamination from these items to prevent damage and unsatisfactory

performance.

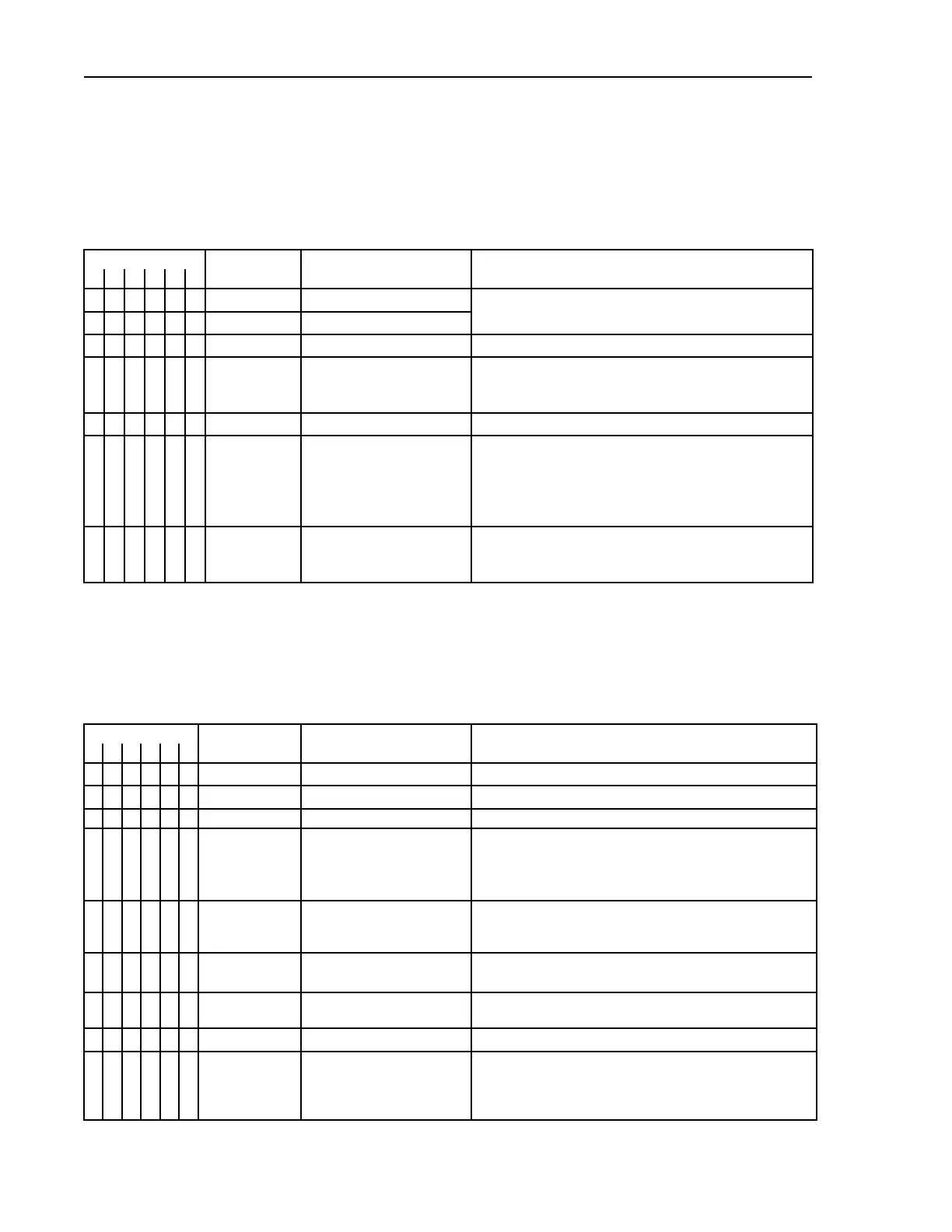

Table 2. Filters, Screens, and Sensitive Components

Mark

Do this each

Component More Data. See also Section 3.1.2 , page 18

1 2 3 4

5 6

x

40 to 60 hours inverter fans, vents, filters See Figure 9, page 26 . Keep good air flow.

x

600 hours

motors

Keep good air flow.

x

2400 hours entire machine Remove excessive dust and dirt.

x

day* chemical inlet areas Some chemical supplies that stay on machine surfaces

will cause corrosion damage. See Section 3.2.3 , page

26 and Section 3.1.2 , page 18. See also, Section 2.3 ,

page 11 for background information.

x

day* self-purging filter (and

regulator) for compressed

air

See Figure 16, page 30. Make sure the bowl drains

automatically.

x

200 hours filter element for the filter

(and reguator)

Replace the filter if you cannot remove contamination.

x

1200 hours mufflers, quick exhaust

valves

See Figure 17, page 31

x

200 hours strainer(s) for air inlet See Figure 15, page 29

x

2400 hours strainer in water regulator

for optional supply injec-

tor and pumped chemicals

on some models.

See Figure 11, page 27

Routine Maintenance

Loading...

Loading...