20

Pellerin Milnor Corporation

CAUTION:

Bad lubricant — will decrease the life of components.

� Make sure that all equipment and fittings used to apply lubricants are

clean.

� Use only the given lubricants or equivalent lubricants that have the

same specifications.

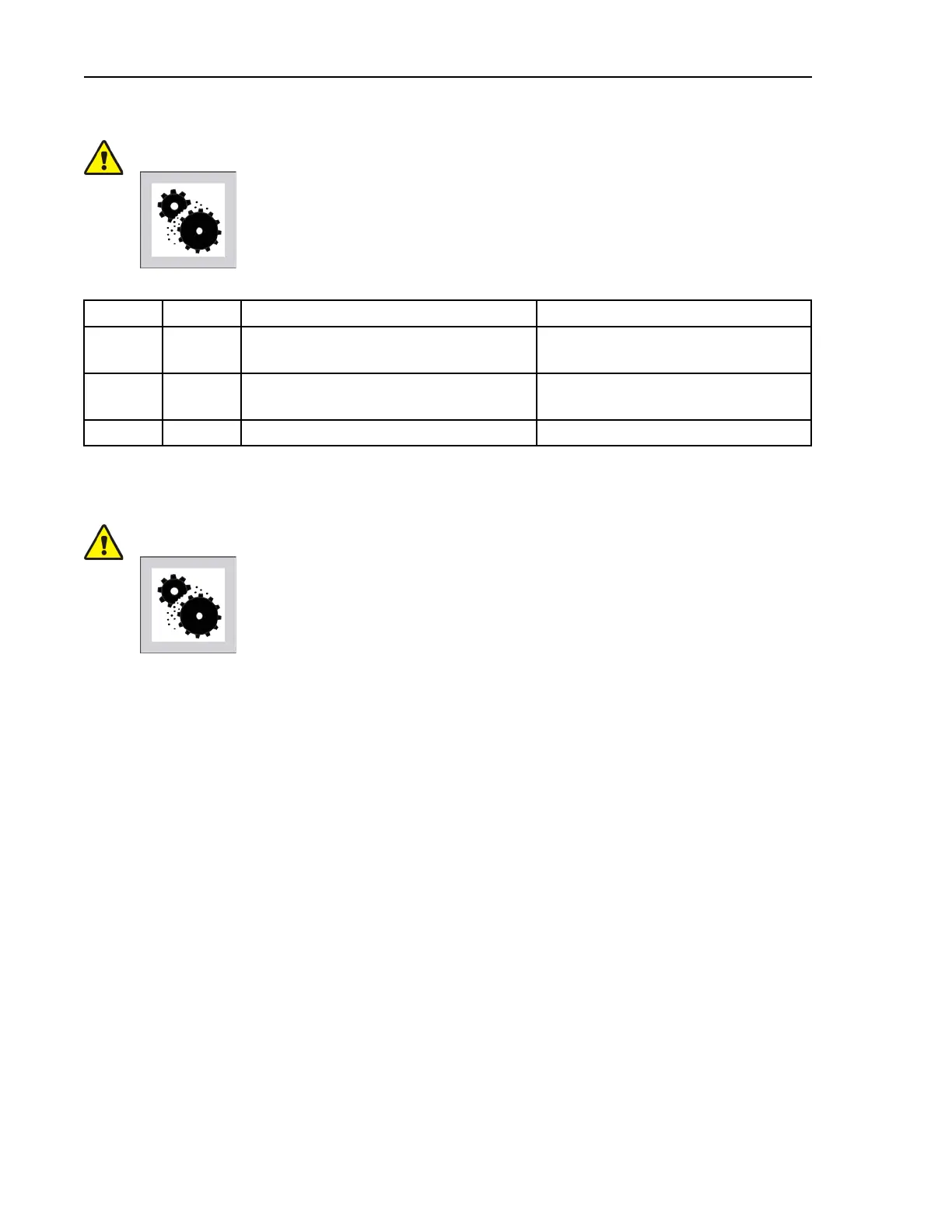

Table 8. Lubricant Identification

Code

Type

Trademark Name

Application Example

EM

grease

Mobil Polyrex EM or as given on the

motor nameplate

motor bearings

EPLF2

grease

Shell Alvania EP (LF) Type 2 drive shaft bearings and bushings,

ball joints, chain drives

1030

oil Shell Rotella T 10W30 Hydro-cushion™ cylinders

3.1.4 Grease Gun Procedures

BNUUUH01.R05 0000335825 A.5 A.26 A.3 9/21/21 1:10 PM Released

CAUTION: Hydraulic pressure — can push out seals and push grease into unwanted

areas (example: motor windings).

� Use a hand grease gun. A power grease gun gives too much pressure.

� Know the quantity of grease your grease gun gives each cycle (each

stroke).

� Operate the grease gun slowly (10 to 12 seconds for one cycle).

� Add only the specified quantity. Stop if new grease come out of a drain port or other

opening.

� Remove spilled grease from belts and pulleys.

The tables give grease quantities in fluid ounces (fl oz) and milliliters (mL). You can also use

grease gun cycles (strokes). A cycle is each time that you pull the trigger. One cycle is usually ap-

proximately 0.06 fl oz (1.8 mL). Your grease gun can give more or less than this. Measure the

output of your grease gun as follows:

• Make sure that the grease gun operates correctly.

• Operate the grease gun to put grease into a small container with fluid ounce or milliliter incre-

ments. Pull the trigger fully and slowly.

• Add a sufficient quantity of grease to measure accurately. Count the number of cycles of the

grease gun (the number of times that you pull the trigger).

• Calculate the quantity for each cycle of the grease gun, as in the following examples.

Example: 2 fl oz / 64 cycles = 0.031 fl oz for each cycle

Example: 59 mL / 64 cycles = 0.92 mL for each cycle

Routine Maintenance

Loading...

Loading...