Pellerin Milnor Corporation 35

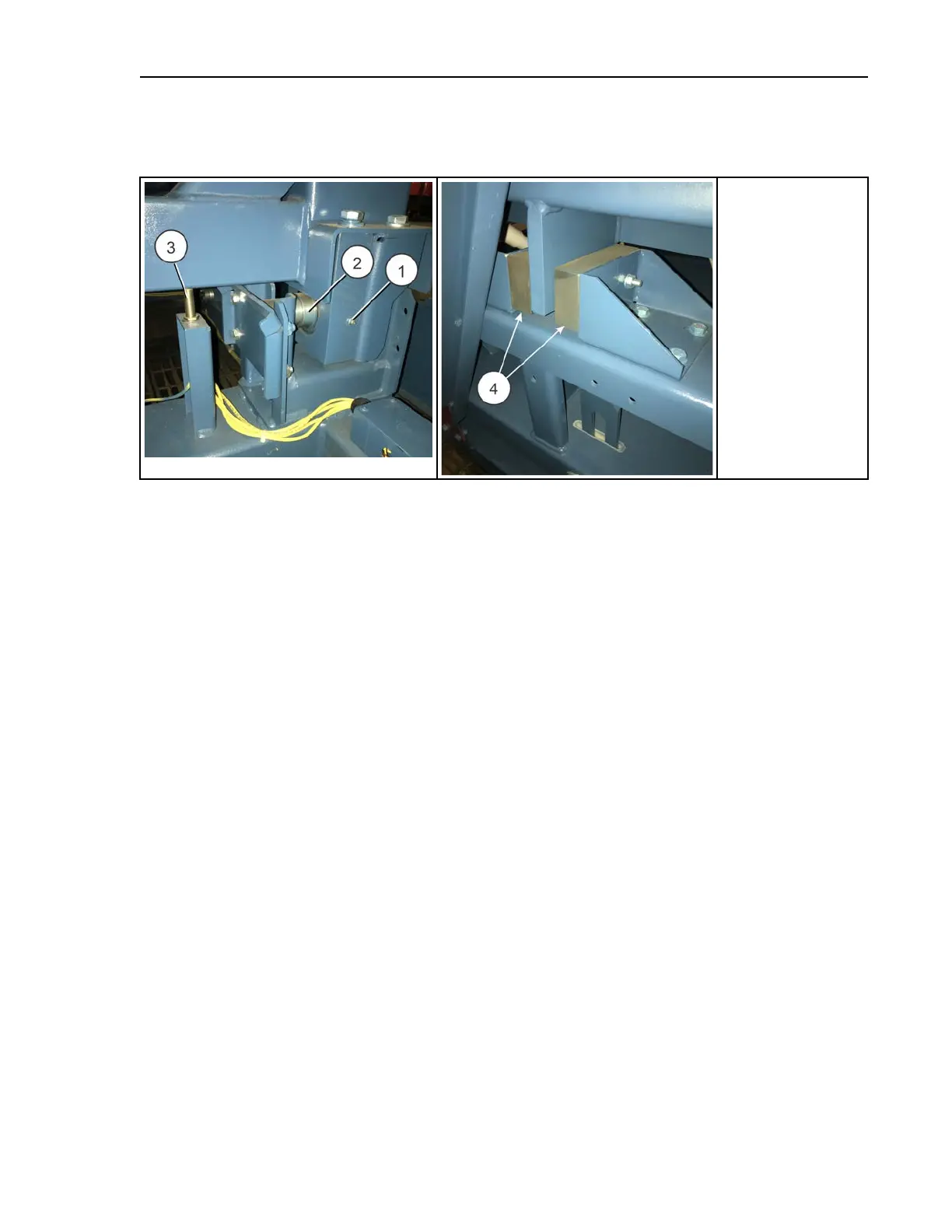

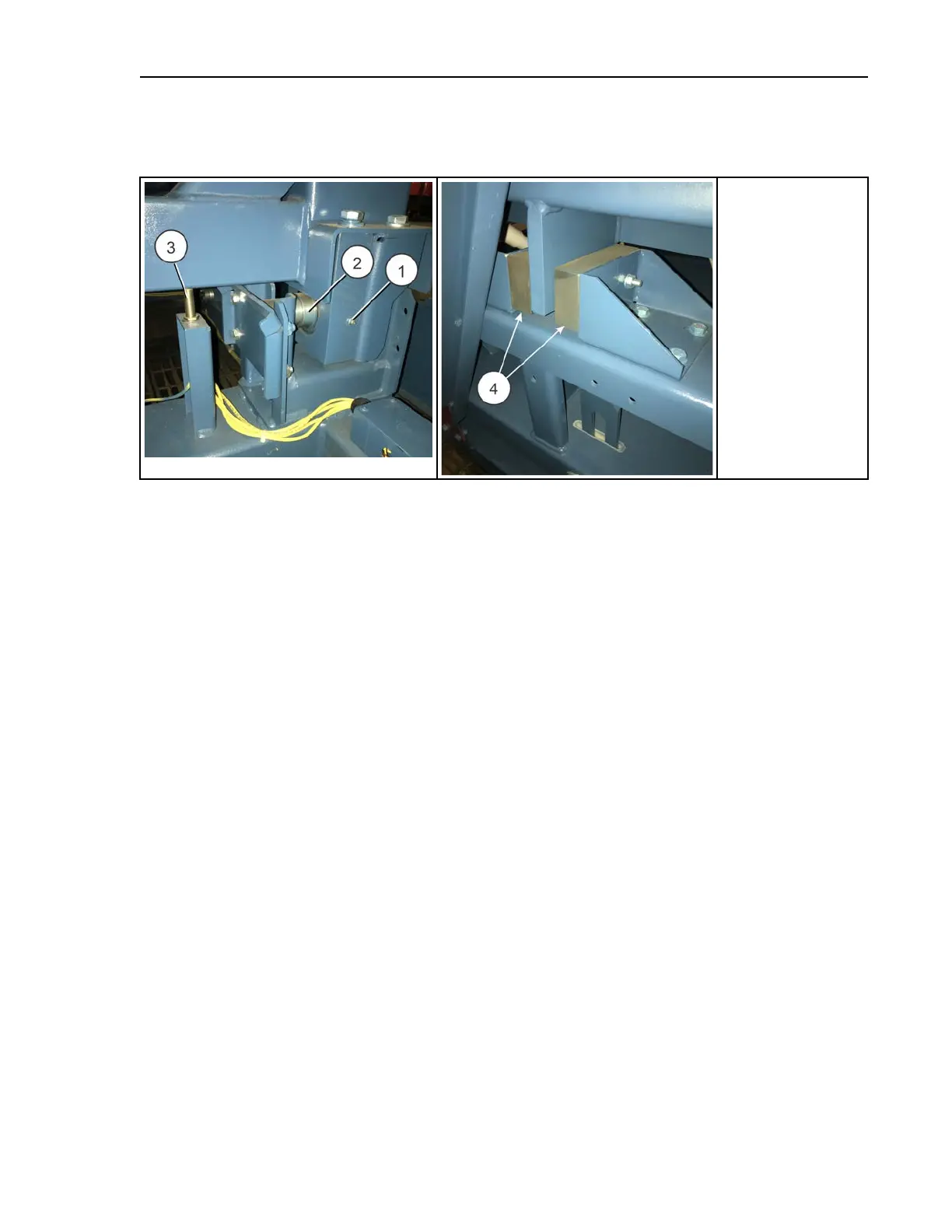

Figure 22. Other Routine Maintenance Items on Each Side of MWF_ Air Tilt Washer-extractor

Models

Legend

1...Grease port for

tilt pivot.

2...Pivot

3...Proximity

switch

4...Tilt bumpers

3.3.3 About the Shock Absorbers

BNWBUH01.C04 0000336165 A.5 B.15 A.7 10/13/21 11:58 AM Released

Milnor

®

washer-extractors with a rubber spring suspension also have shock absorbers. The shock

absorbers have a different type of connection than those for automobiles. It is not necessary to re-

place the shock absorbers at specified intervals. It is only necessary to replace them if there is an

indication that they are damaged or very worn.

Examine the shock absorbers at the intervals given in the maintenance summary. It is necessary

to replace a shock absorber if you see oil come out from the mechanism (see the figure that fol-

lows). This shows that seals are worn. It is also necessary to replace the shock absorber if the rub-

ber in a connector is very worn or missing.

Bad shock absorbers will let the shell move too much when the machine operates. If severe move-

ment occurs and you are not sure of the cause, you can do a test of the shock absorbers as

follows:

1. Remove the shock absorber from the machine.

2. With your body weight, compress the length of the shock absorber against a hard surface. A

serviceable shock absorber compress slowly. It will also expand slowly to its initial length

when you release it. If it compresses or expands quickly, the shock absorber is bad.

Routine Maintenance

Loading...

Loading...