5-3

6. Verify the realtime CO

2

value is within 6.0 ± 0.3% in the [Calibrate CO2] menu.

5.2.2.3 Calibration

Tools required:

A steel gas cylinder with 5±0.03% CO

2

, 21.0% O

2

and balance gas N

2

(P/N 0075-00-0033-01), or a steel gas cylinder

with:

CO

2

concentration 3% - 7%

a/c ≤ 0.01 (where a = absolute gas concentration accuracy, c = gas concentration)

balance gas N

2

T-shape connector

Tubing

To perform a calibration:

1. Make sure that the sidestream or microstream CO

2

module is warmed up.

2. Check the airway for leaks.

3. Select [Main Menu]

→

[Maintenance >>]

→

[User Maintenance >>]

→

enter the required password

→

[Module

Maintenance>>]→[Maintain CO2 >>]

→

[Calibrate CO2 >>].

4. In the [Calibrate CO2] menu, select [Zero].

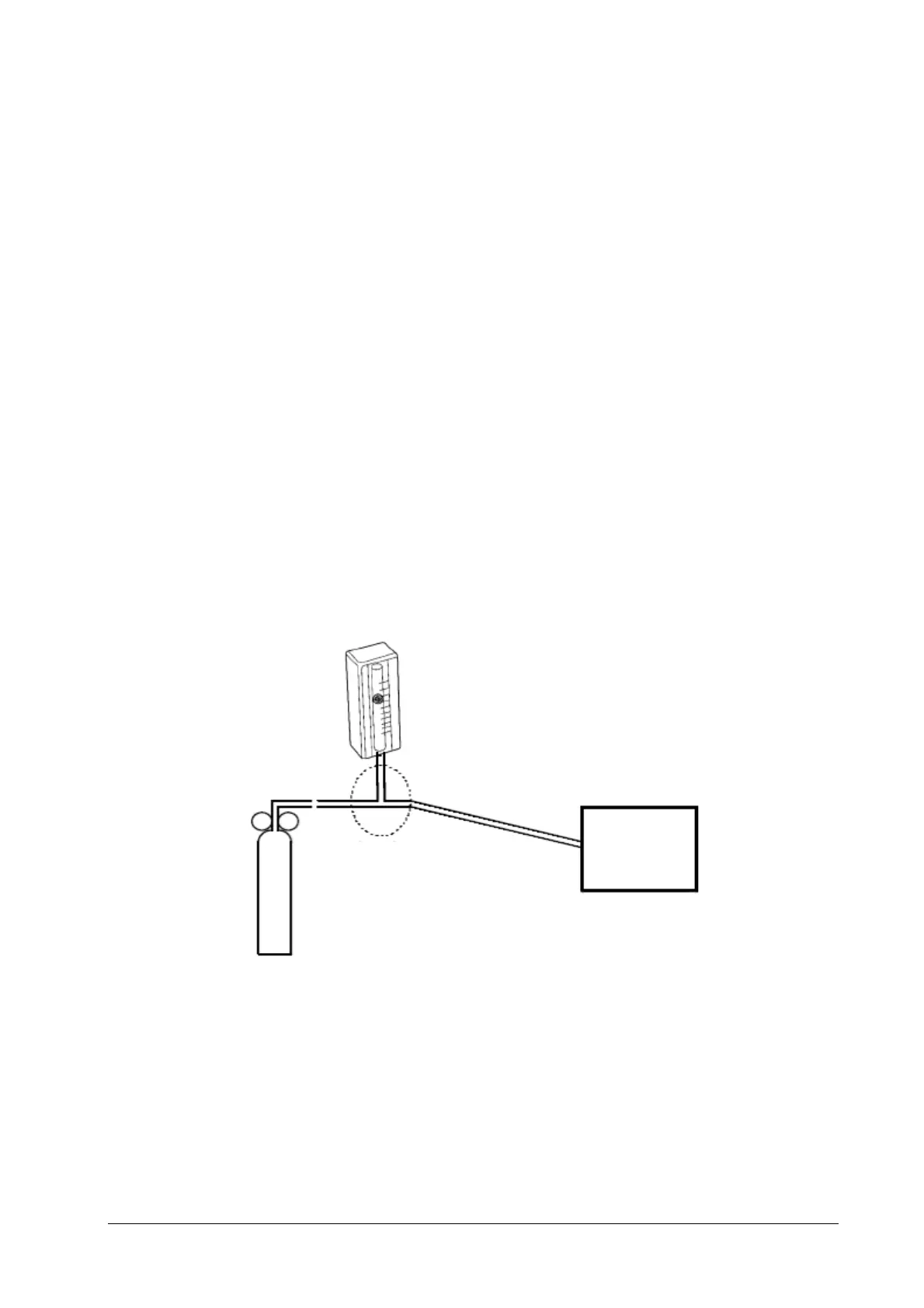

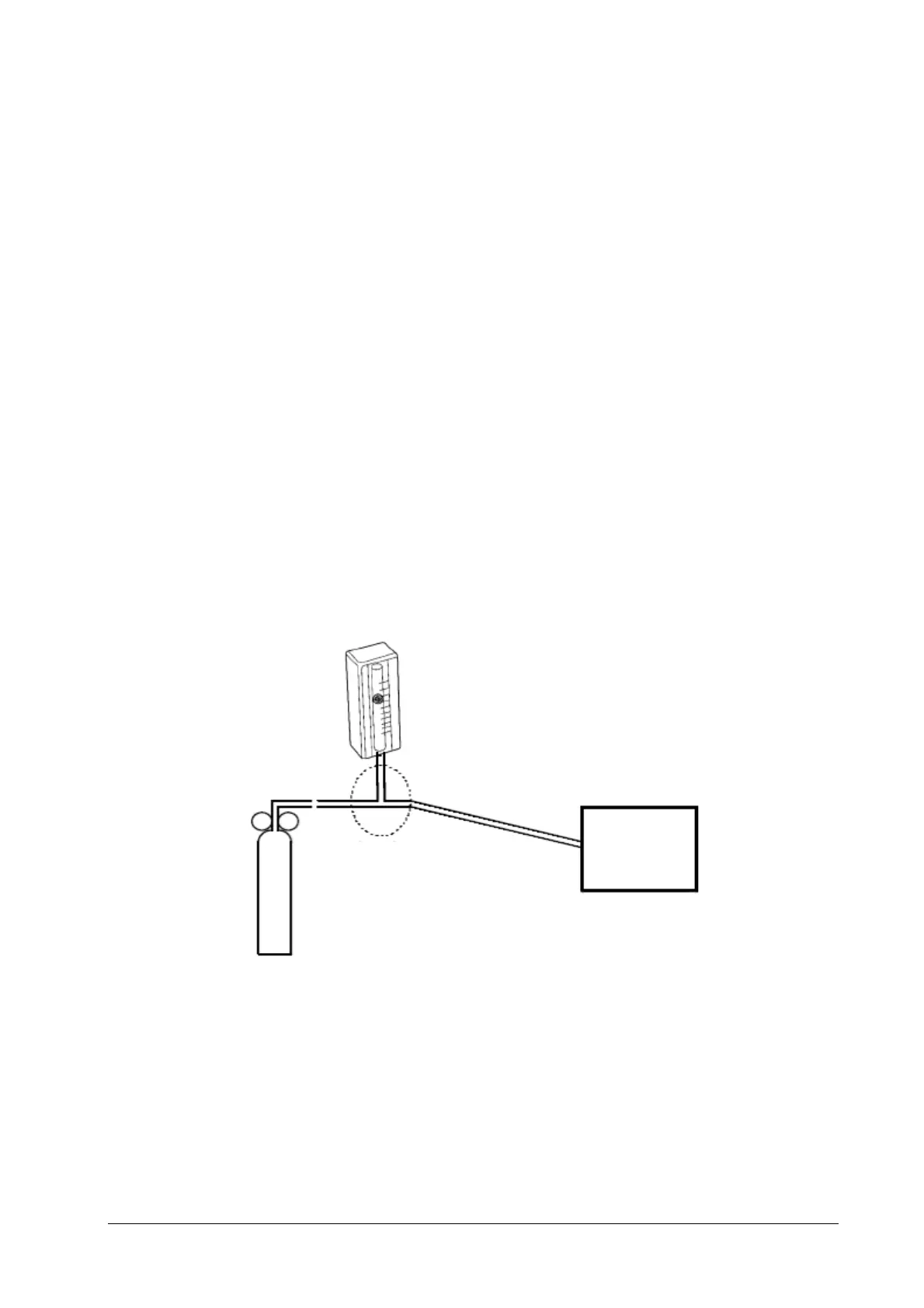

5. After the zero calibration is finished successfully, connect the equipment as follows:

6. Open the valve to flow CO2 and make sure that there is flow sufficient to vent to atmosphere.

7. In the [Calibrate CO2] menu, enter the CO2 concentration in the [CO2] field.

8. In the [Calibrate CO2], the measured CO2 concentration is displayed. After the measured CO2 concentration

becomes stable, select [Calibrate CO2] to calibrate the CO2 module.

If the calibration is finished successfully, the message [Calibration Completed!] is displayed in the [Calibrate CO2]

menu. If the calibration failed, the message [Calibration Failed] is displayed. In this case, perform another calibration.

Monitor

Cylinder

Flowmeter

Relief valve

T-shape connector

Sampling line

Loading...

Loading...