5-6

8. If the calibration is finished successfully, the message [Calibration Completed!] is displayed. If the calibration

failed, the message [Calibration Failed] is displayed. In this case, perform another calibration.

CAUTION

Calibrate the O

2

module, if it has been transported for long distance.

5.3 Performance Tests

Performance test are designed to ensure that measurement results are accurate. The following sections provide a list

of performance and accuracy tests and their recommended frequencies.

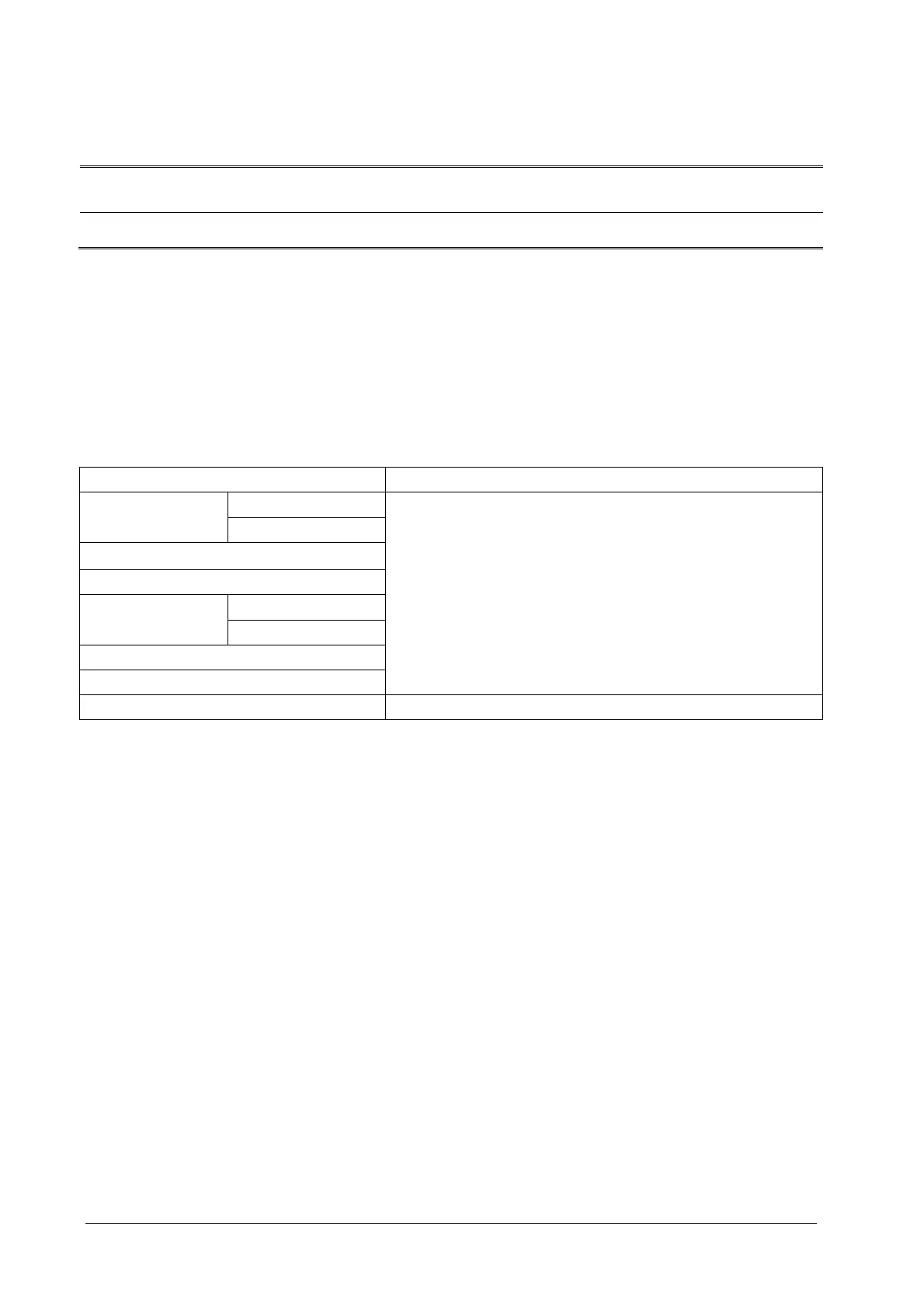

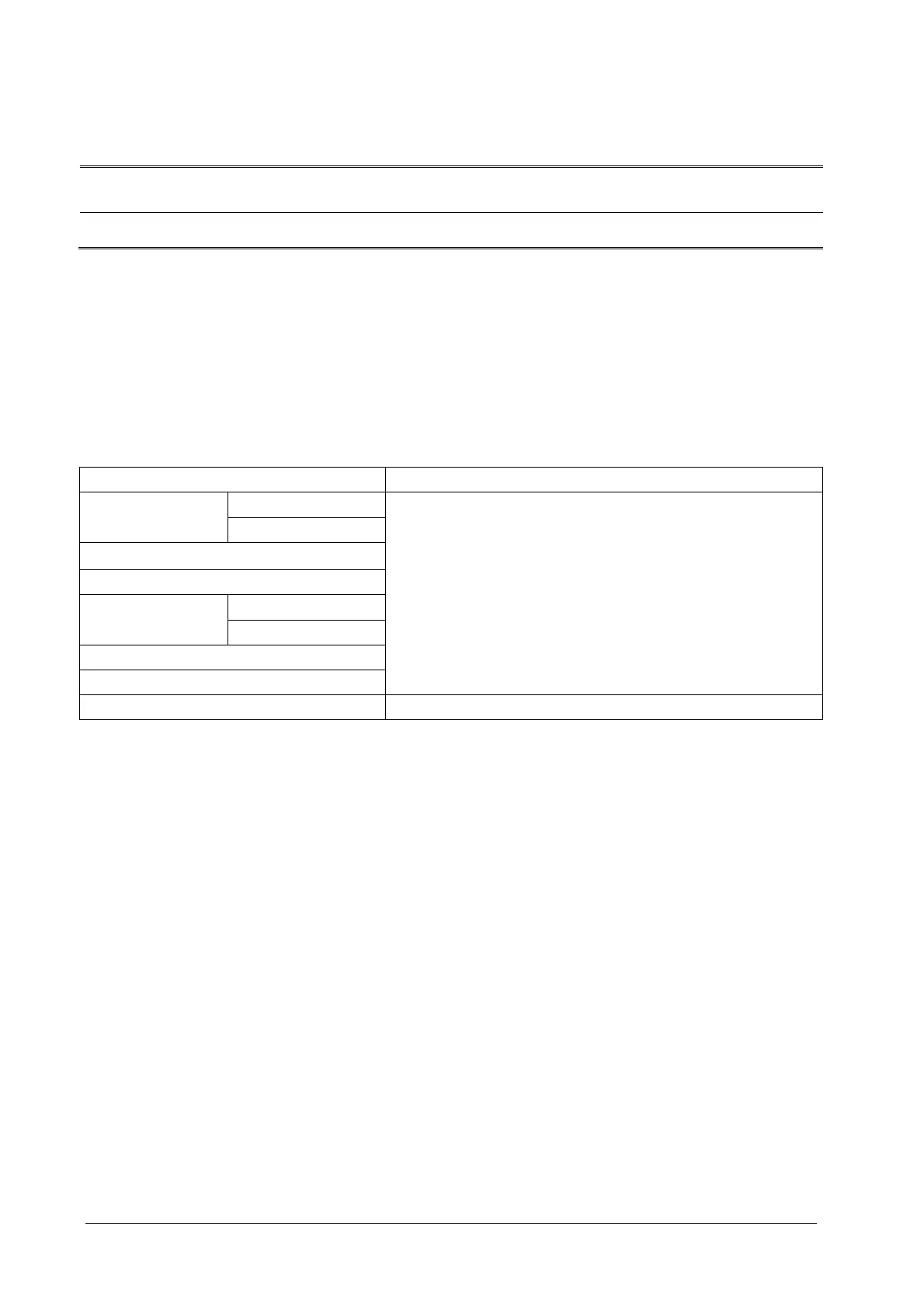

5.3.1 Performance Test Frequencies

Visual Inspection 1. When first installed or reinstalled.

ECG test Performance test 1. If the user suspects that the measurement is incorrect.

2. Following any repairs or replacement of relevant module.

3. Once a year for NIBP and CO

2

tests.

4. Once every two years for other parameter module performance tests.

Verification

Resp performance test

SpO

2

test

NIBP test Pressure check

Leakage test

Temp test

IBP performance test

Analog output performance test If the user suspects that the analog output does not work.

5.3.2 Visual Inspection

Inspect the equipment for obvious signs of damage. Follow these guidelines when inspecting the equipment:

Carefully inspect the case, display screen, buttons and knob for obvious signs of damage.

Inspect the power cord, wall mount, and module accessories for obvious signs of damage.

Inspect all external connections for loose connectors, bent pins or frayed cables.

Inspect all connectors on the equipment for loose connectors or bent pins.

Make sure that safety and information labels on the equipment are clearly legible.

Loading...

Loading...