5-9

4. Select [Main Menu] → [Maintenance >>] →[User Maintenance >>] →enter the password→[Module

Maintenance >>] →[NIBP Leakage Test]. The message [Leakage Testing…] is displayed in the NIBP parameter

area.

5. The cuff automatically deflates after 20 s, indicating NIBP leakage test is completed.

6. 6. If no message is displayed in the NIBP parameter area, it indicates that the system has no leakage. If the

message [NIBP Pneumatic Leak] is displayed, it indicates that the system may have a leak. In this case, check if

all connections are good and the cuff and tubing have no leakage. Perform the test again after making sure all

connections are sealed.

You can either perform a manual leakage test:

1. Perform steps 1 to 4 in the NIBP Accuracy Test section.

2. Raise the pressure in the rigid vessel to 250 mmHg with the Manometer bulb. Then, wait for 5 seconds to let the

measured values becoming stable.

3. Record the current pressure value, and meanwhile use a time counter to count the time. Then, record the

pressure value after 60 s.

4. Compare the two pressure values and make sure the difference should not be greater than 6 mmHg.

5.3.6.2 NIBP Accuracy Test

Tool required:

T-shape connector

Appropriate tubing

Manometer bulb

Rigid Vessel with volume 500 ± 25 ml

Reference manometer (calibrated with accuracy equal to or better than 0.75 mmHg)

Follow this procedure to perform the accuracy test:

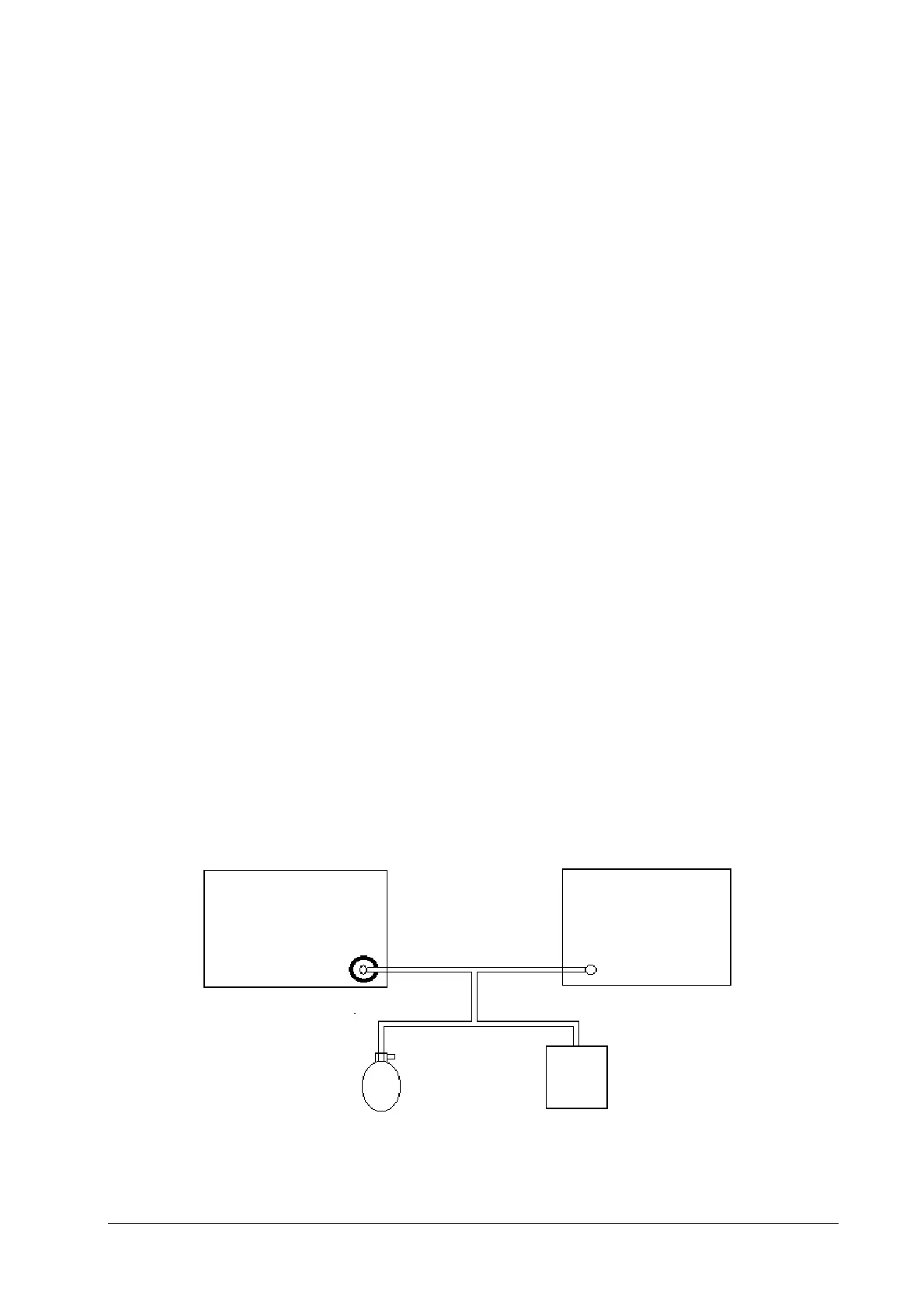

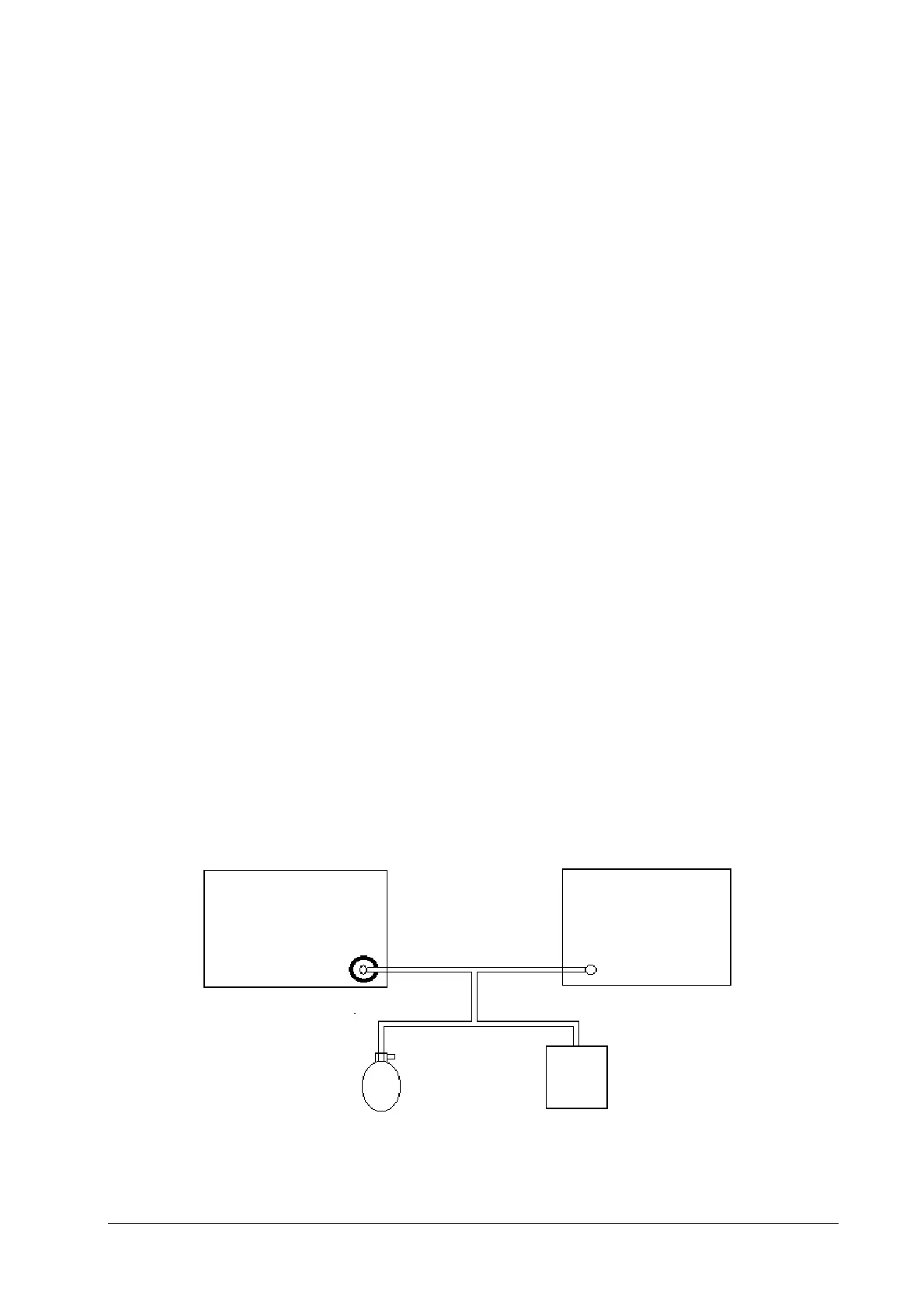

1. Connect the equipments as shown below.

2. Before inflation, check that the reading of the manometer is 0. If not, open the Manometer bulb valve to

atmosphere. When pressure reads 0, close the bulb valve.

Monitor

Connector for NIBP

cuff

Standard

sphygmomanometer

Appropriate tubing

Manometer bulb Rigid Vessel

Loading...

Loading...