33

Maintenance

Have a qualified service technician check the vacuum motor carbon motor brushes once a year or after 300 operating hours.

The brush motor and transaxle motor carbon brushes should be checked every 500 hours or once a year.

NOTE: Refer to the Service Manual for more detail on maintenance and service repairs.

Regularly scheduled lubrication of certain machine parts should be performed to insure trouble-free operation of the

machine. Apply a generous amount of grease into the fittings on the machine until grease seeps out around the bearings.

The grease points are listed below:

• Rear caster swivel (2)

Apply lubricant or light machine oil to lubricate the:

• Pivot mounting point of the squeegee lift mechanism to the chassis (1)

• Rear squeegee caster wheel axle (2)

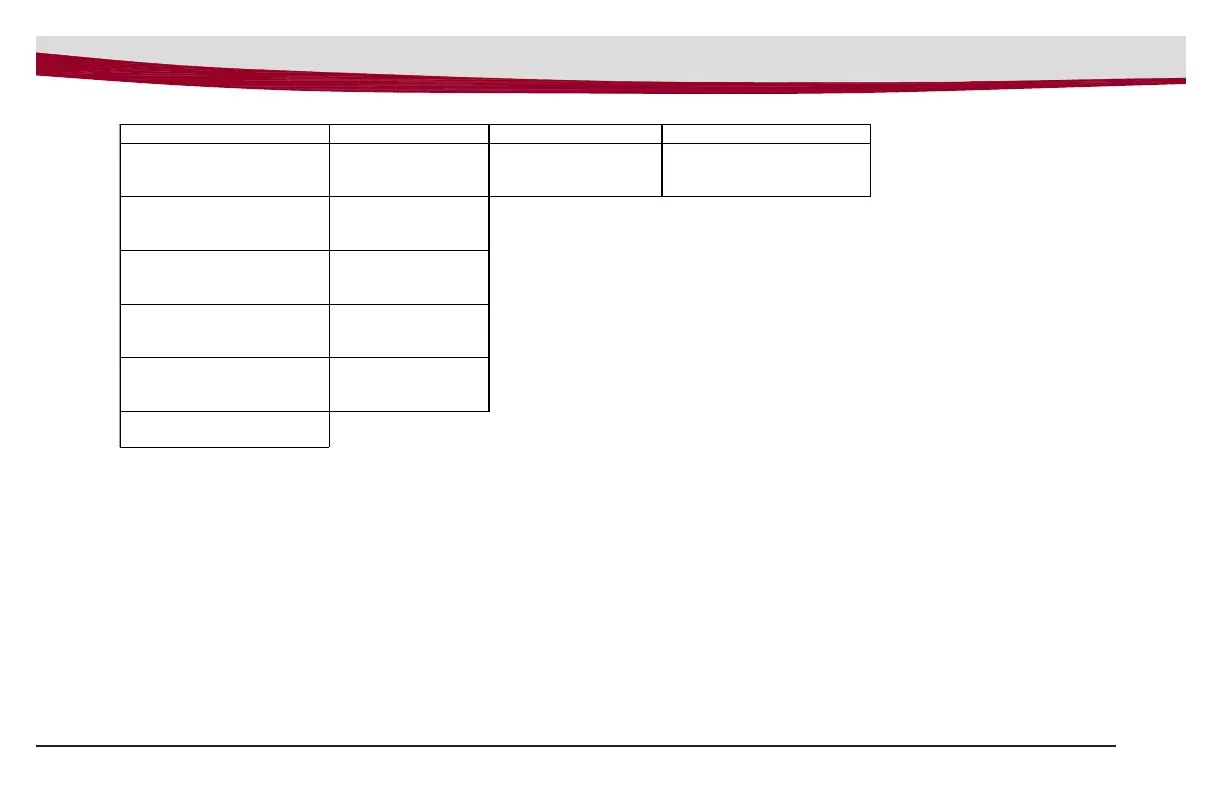

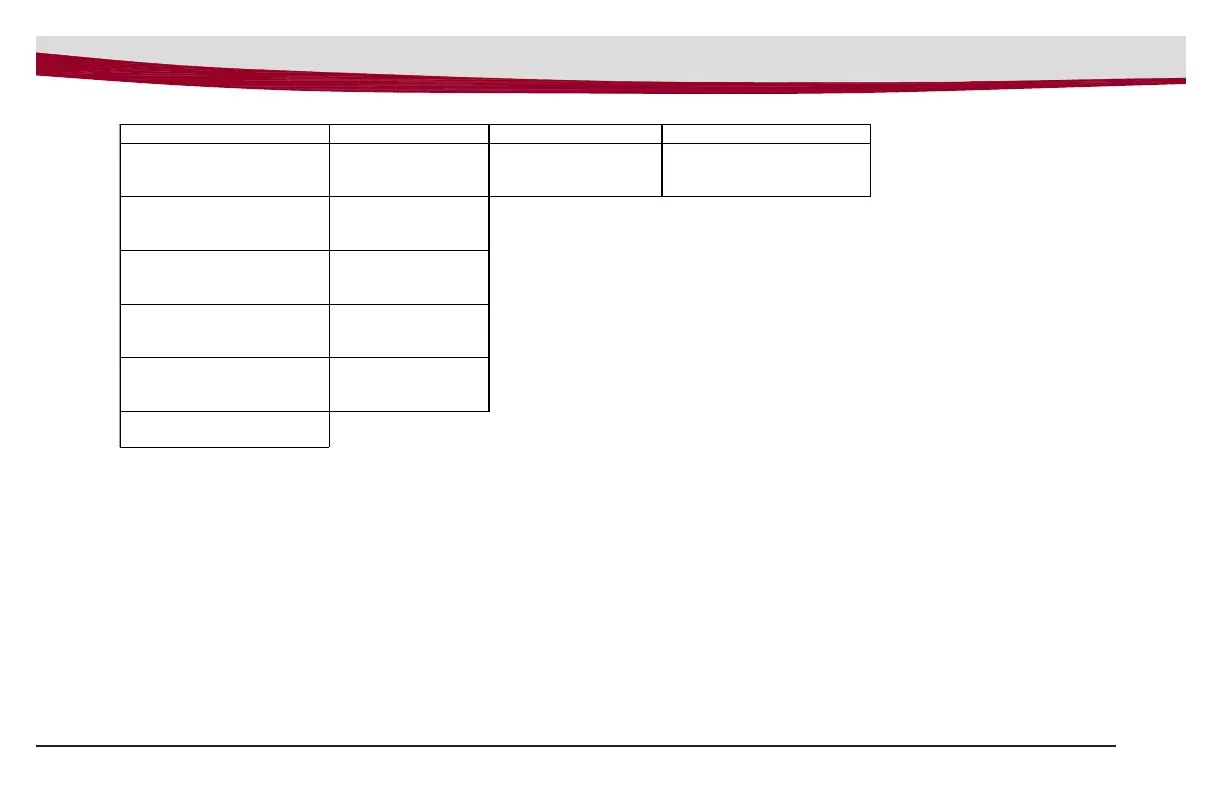

Daily Weekly Mo nthly Yearly

Charge Batteries

Inspect Brush

Deck Side Skirts

for Debris

Lubrication –

Grease Fittings

Check Carbon

Brushes

Check/Clean Tanks &

Hoses

Inspect and

Clean In-Line

Solution Filter

Check/Clean/Rotate

the Brushes

Rinse off the

underside of

brush deck

Check/Clean the

Squeegee

Check Each

Battery Cell(s)

Water Level

Check/Clean Vacuum

Shut-Off Float in

Recovery Tank

Inspect and

Clean spray jet

tip

Clean the brush deck

debris tray.

Loading...

Loading...