FUEL SYSTEM

8-21

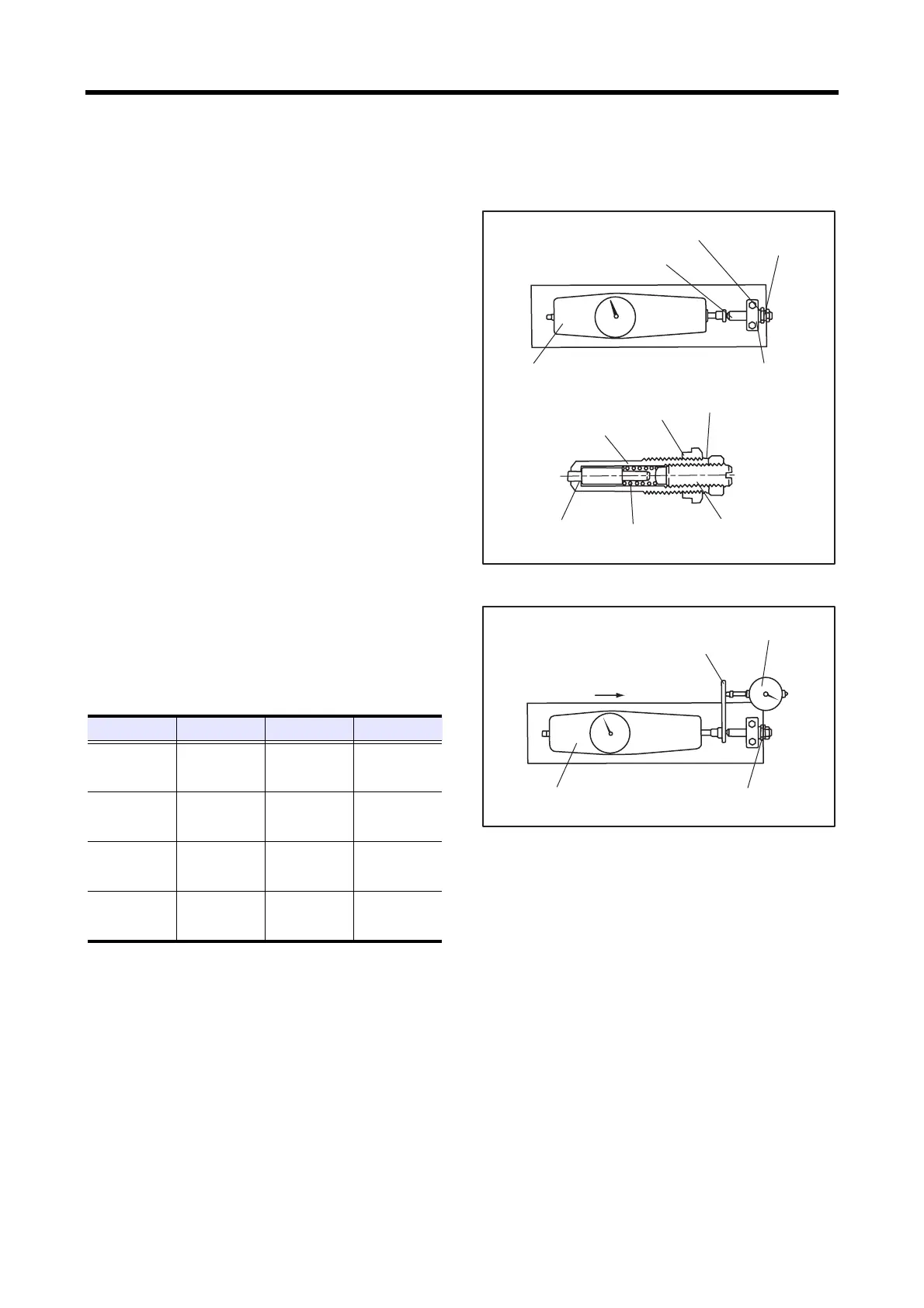

2.9.1 Torque spring set, single spring type

Reassemble the torque spring set of the single spring type as

described in the following:

(1) To lightly tighten adjusting screw, turn the adjusting

screw with a screwdriver until you feel resistance. At

the position where you feel resistance, secure the

adjusting screw lightly using lock nut.

(2) Set the scale to zero. Turn the torque spring case until

the scale reading reaches the load value “A” g in the

table below. At this position, secure the adjusting screw

using the speical nut.

(3) Temporarily loose the adjusting screw until "A" g load

decreases by approx. 200 g [7.05 oz.] and then tighten

the adjusting screw again until the load reaches “B” g in

the table below. At this position, tighten the lock nut to

the specified torque to secure the adjusting screw.

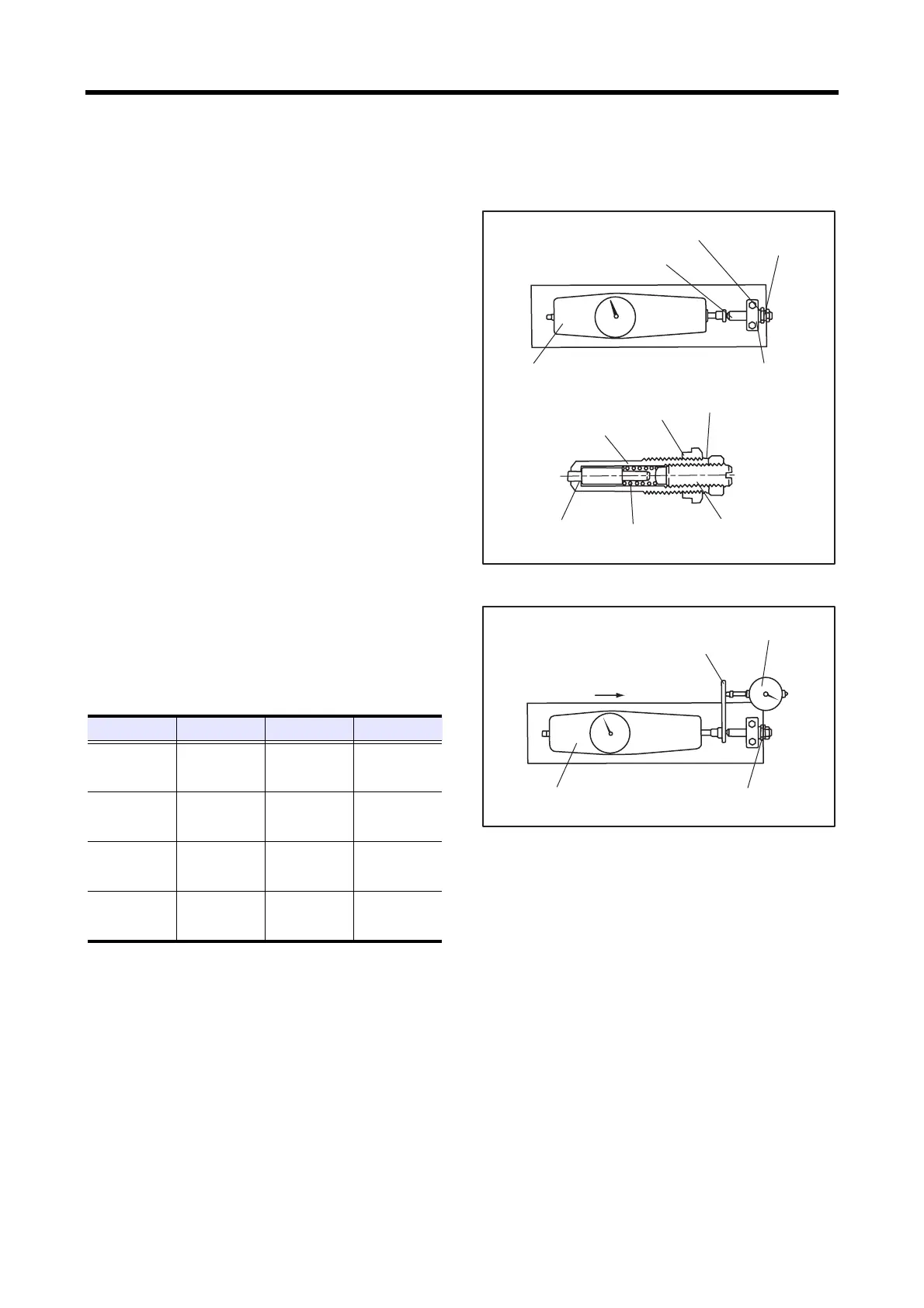

(4) To check that the torque spring set is adjusted to the

appropriate load, place the torque spring set as shown

in the illustration. Slowly push the scale to the torque

spring set until the spring stopper moves or the pointer

of the dial gauge swings. Check the load against the

torque spring at that moment is equal to "C" g of the

table below.

Note: Load values (A, B and C) vary based on models.

Setting of torque spring of single spring type

Inspecting torque spring of single spring type

A B C Color

570 0

+10

g

[20.11

0

+0.35

oz.]

570

0

+10

g

[20.11

0

+0.35

oz.]

570

-30

+20

g

[19.40

-1.06

+0.71

oz.]

Green

1520

0

+10

g

[53.62

0

+0.35

oz.]

1520

-10

0

g

[53.62

-0.35

0

oz.]

1500

-30

+20

g

[52.91

-1.06

+0.71

oz.]

Red

970

0

+10

g

[34.22

0

+0.35

oz.]

970

-10

0

g

[34.22

-0.35

0

oz.]

950

-30

+20

g

[33.51

-1.06

+0.71

oz.]

Yellow

1270

0

+10

g

[44.80

0

+0.35

oz.]

1270

-10

0

g

[44.80

-0.35

0

oz.]

1250

-30

+20

g

[44.09

-1.06

+071

oz.]

Purple

Fixed scale

Torque spring case

Torque spring case

Special nut

Special nut

Lock nut

Lock nut

Adjusting

screw

Spring

stopper

Torque spring

Adjusting screw

7.8VQ11.8N㨯m

{0.8 VQ1.2kgf㨯m}

[5.8 to 9.7 lbf㨯ft]

Sliding scale

Block gauge

Dial gauge

Special nut

Loading...

Loading...