WELDING

BASE OF BODY REPAIR

9-5

NOTES REGARDING WELDING

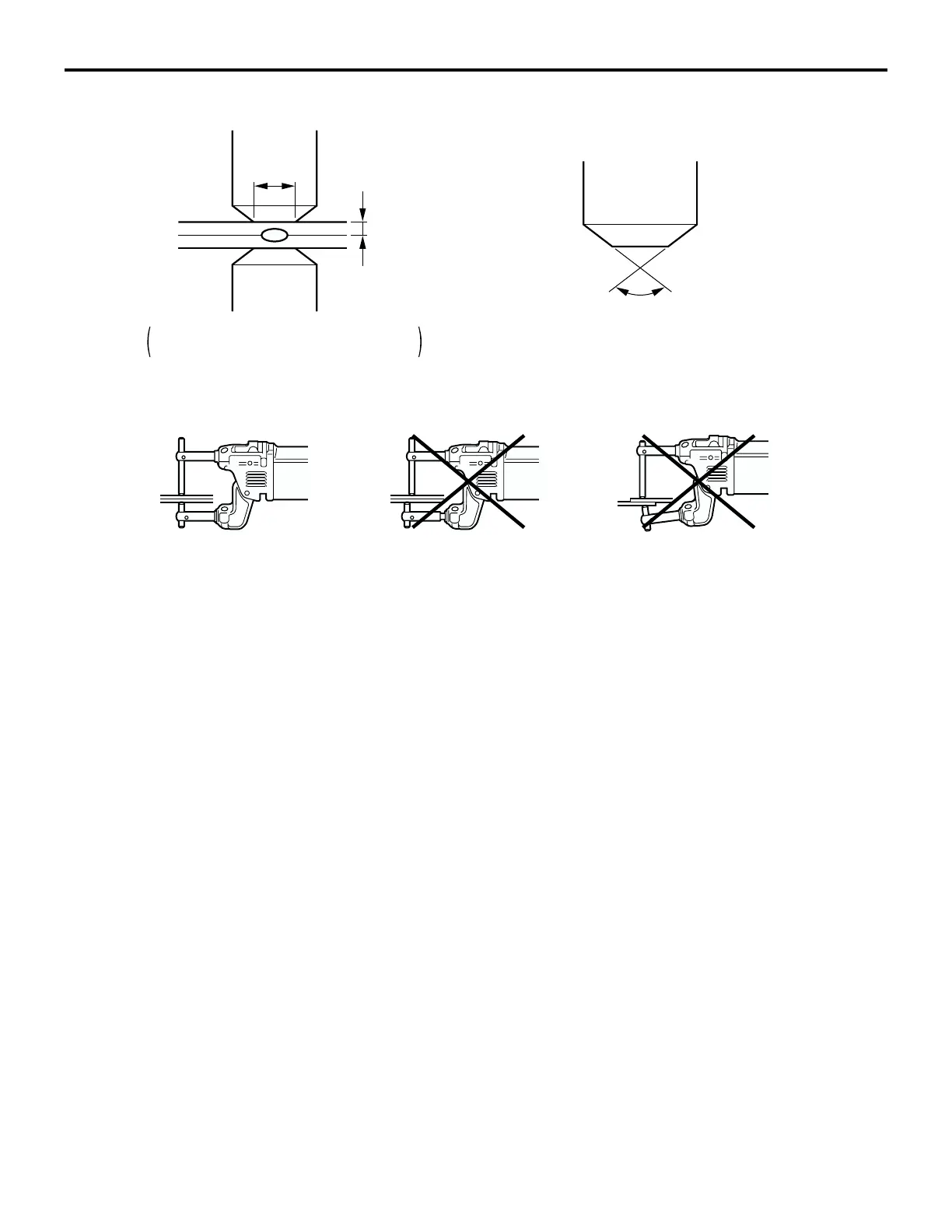

1. Selection of the electrode tips

• Select the electrode tips according to the

thickness of the panels to be welded.

D = 2t + 3 mm (D = 2t + 0.1 inch)

• The angle of the tip should be between 90

degree angle and 120 degree angle.

• To always keep the end of tip in the correct

shape, use a tip cutter, file or similar tool to

shape it if it becomes worn.

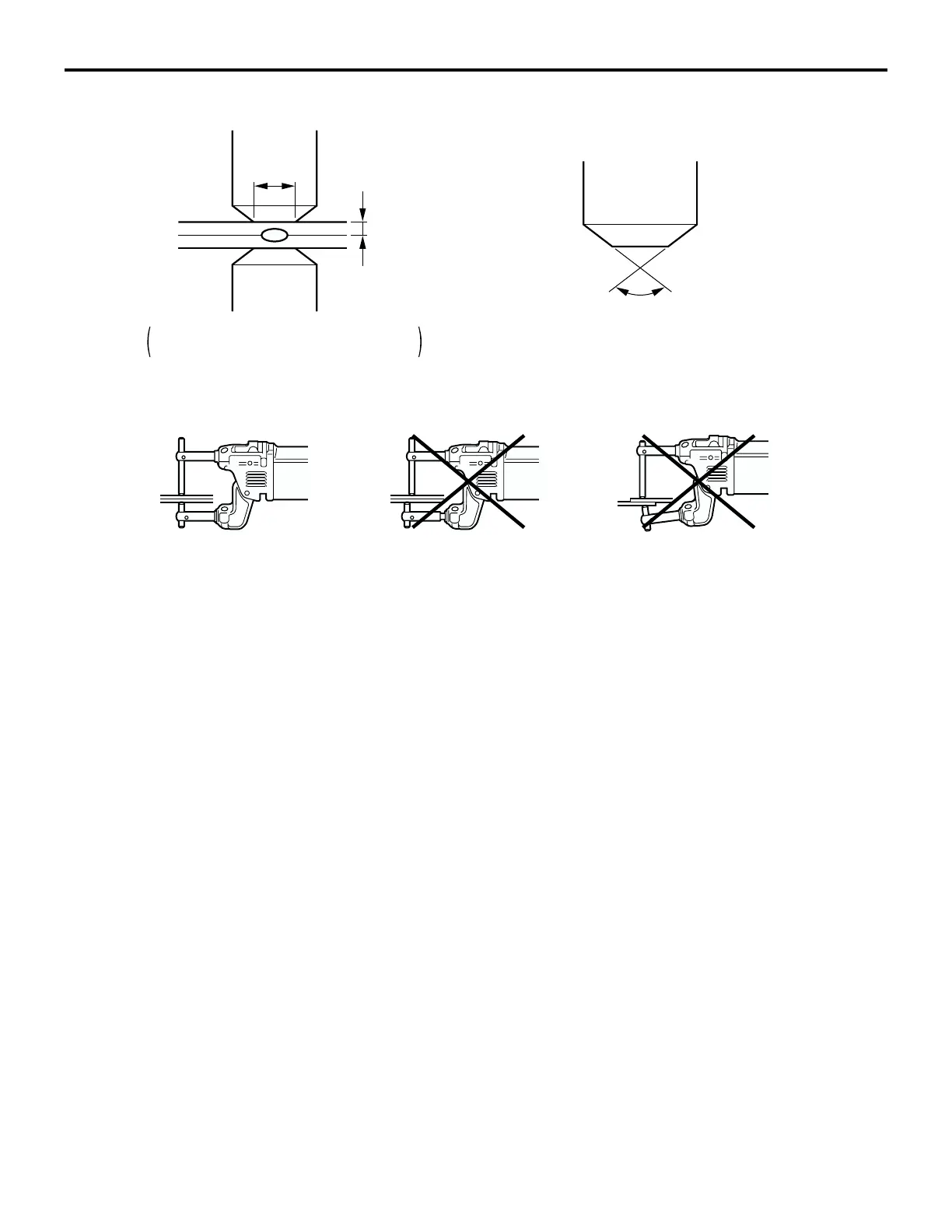

2. Alignment of the electrode tips

• Adjust the arms so that the upper and lower

electrode tips are in a straight line.

3. Alignment and length of the arms

• Adjust the electrode tips so that the upper and

lower arms are parallel.

• Select an appropriate arm length. Note, how-

ever, that the arm length should not be more

than 350 mm (13.8 inches) in order to ensure

nugget strength.

4. The weld points

• The overall strength will increase as the pitch

decreases; however, if the pitch decreases

too much, the current will be short-circuit

diverted to the previous weld point and the

strength of the individual nuggets will be insuf-

ficient.

• Make the spot welds at the center of the

flanges to provide sufficient adhesion. When

welding at an edge, make the spot welds at

least 5 mm (0.2 inch) from the edge of the

flange.

• The number of spot weld points should be the

same as, or slightly more than the number of

original repair welds.

• When spot welding three or more panels

together, if painted surfaces cause a loss of

conductivity, make the welds at the same

places as the factory welds. If this is done,

extra welds will not be necessary, but if extra

welds are necessary, switch to plug welding.

.

AB200030

AB

90˚ - 120˚

D

t

:

:

DIAMETER OF THE ELECTRODE TIP

THICKNESS OF THE PANEL

t

D

Loading...

Loading...