WELDING

BASE OF BODY REPAIR

9-6

WELDING REQUIREMENTS

Standard steel plate (SPCC, etc.)

CAUTION

If the total thickness of the plates at the weld

places is 3 mm (0.12 inch) or more, use plug

welding, because spot welding will not provide

sufficient welded strength.

Example

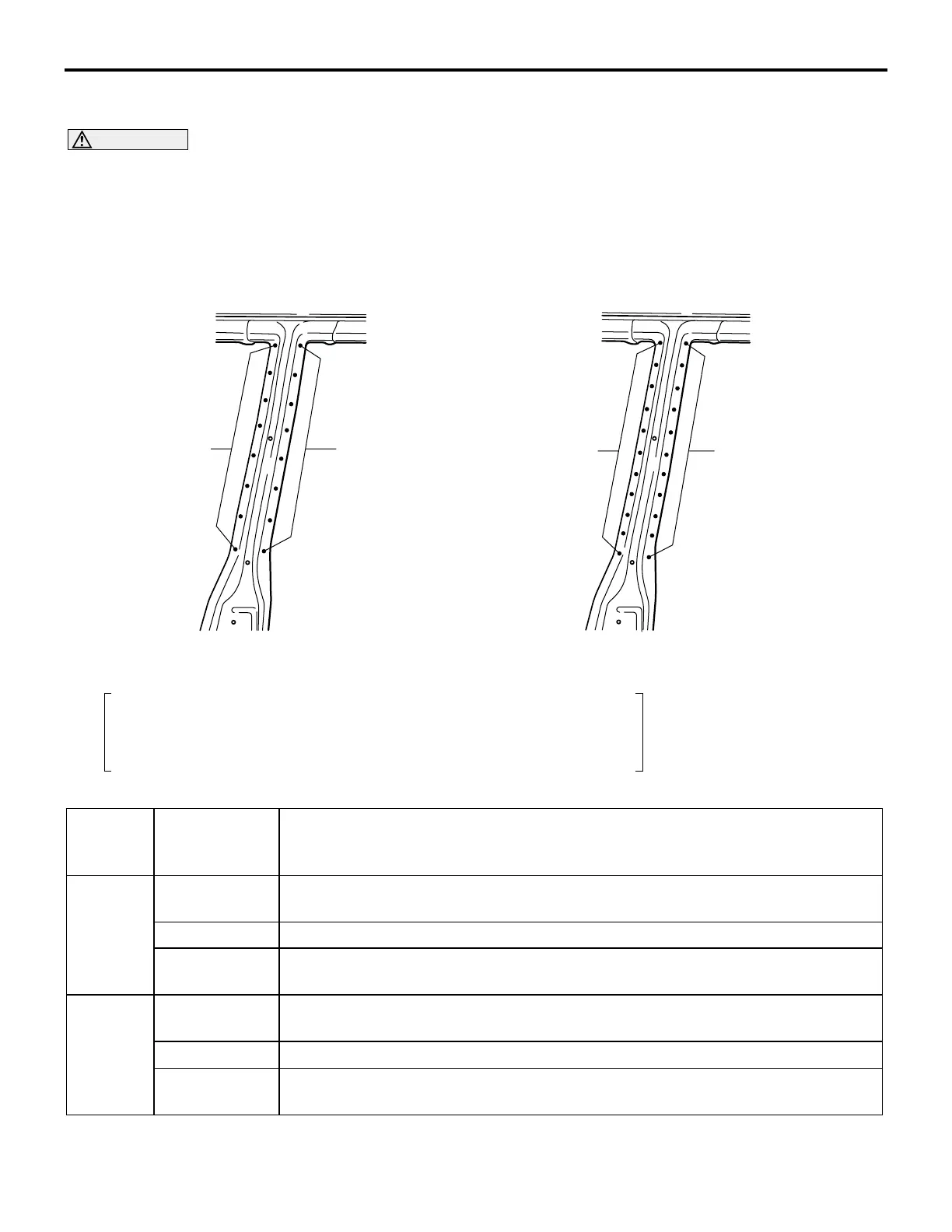

• Center pillar (outer): plate thickness 1.4 mm (0.06

inch), material SPCC

• Center pillar (inner): plate thickness 1.5 mm (0.06

inch), material SPCC

The number of weld points are as below when the

outer and inner center pillars are repaired by weld-

ing.

*: For welding steel plates of different thickness, con-

form to the welding conditions for the thinner plate.

.

AB200031

AB

FACTORY WELDS (F)

8 POINTS 8 POINTS

11 POINTS 11 POINTS

REPAIR WELDS (R)

As shown by the Welding Requirements table, the number of repair welds is as follows.

8 (points) × 130 (%) = 10.4 (points)

The number of weld points should, therefore, be ten or eleven.

If, however, a pitch of 26 mm (1.0 inch) or more cannot be maintained, the plug

welding method (eight weld points) should be used.

PANEL

THICKNESS*

[mm (in.)]

NUMBER OF REPAIR WELD (PERCENTAGE OF FACTORY WELD)

SAFETY

EQUIPM

ENT

AREA

1.0 (0.04) or

less

100% Same number as factory welds

1.2 (0.05) 150% Maintain pitch of at least 22 mm (0.9 inch); if not possible, plug weld.

1.4 (0.06) or

more

100% Same number as factory welds; plug welding

OTHER

AREA

1.2 (0.05) or

less

100% Same number as factory welds

1.4 (0.06) 130% Maintain pitch of at least 26 mm (1.0 inch); if not possible, plug weld.

1.6 (0.06) or

more

100% Same number as factory welds; plug welding

Loading...

Loading...