WELDING

BASE OF BODY REPAIR

9-7

Galvanized steel plate (SECC)

CAUTION

If the total thickness of the plates at the weld

places is 3 mm (0.1 inch) or more, use plug weld-

ing, because spot welding will not provide suffi-

cient welded strength.

*: For welding steel plates of different thicknesses,

conform to the welding conditions for the thinner

plate.

.

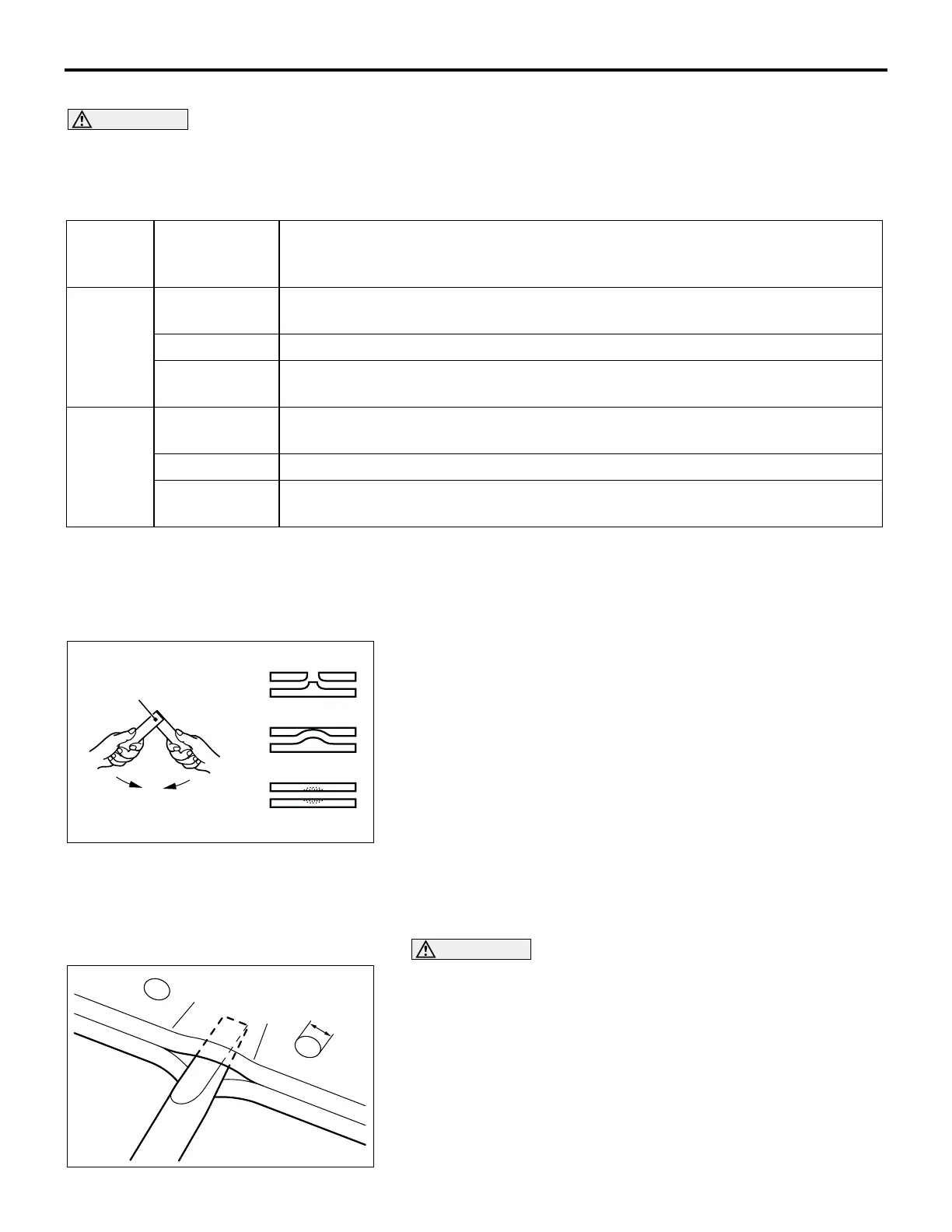

USING A TEST PIECE TO CHECK NUGGET FORMATION

Weld a test piece of the same type of steel plate as the panels

to be welded. Try to twist the piece, and also check the nugget

diameter.

Using the weld point as an axis, apply force in the direction indi-

cated by the arrows in the illustration, and determine the

strength of the weld.

1. Good (The welded part remains at one side.)

2. and 3.

The weld conditions are unsatisfactory; adjust the welding

current, the current application time, and/or the applied

pressure.

.

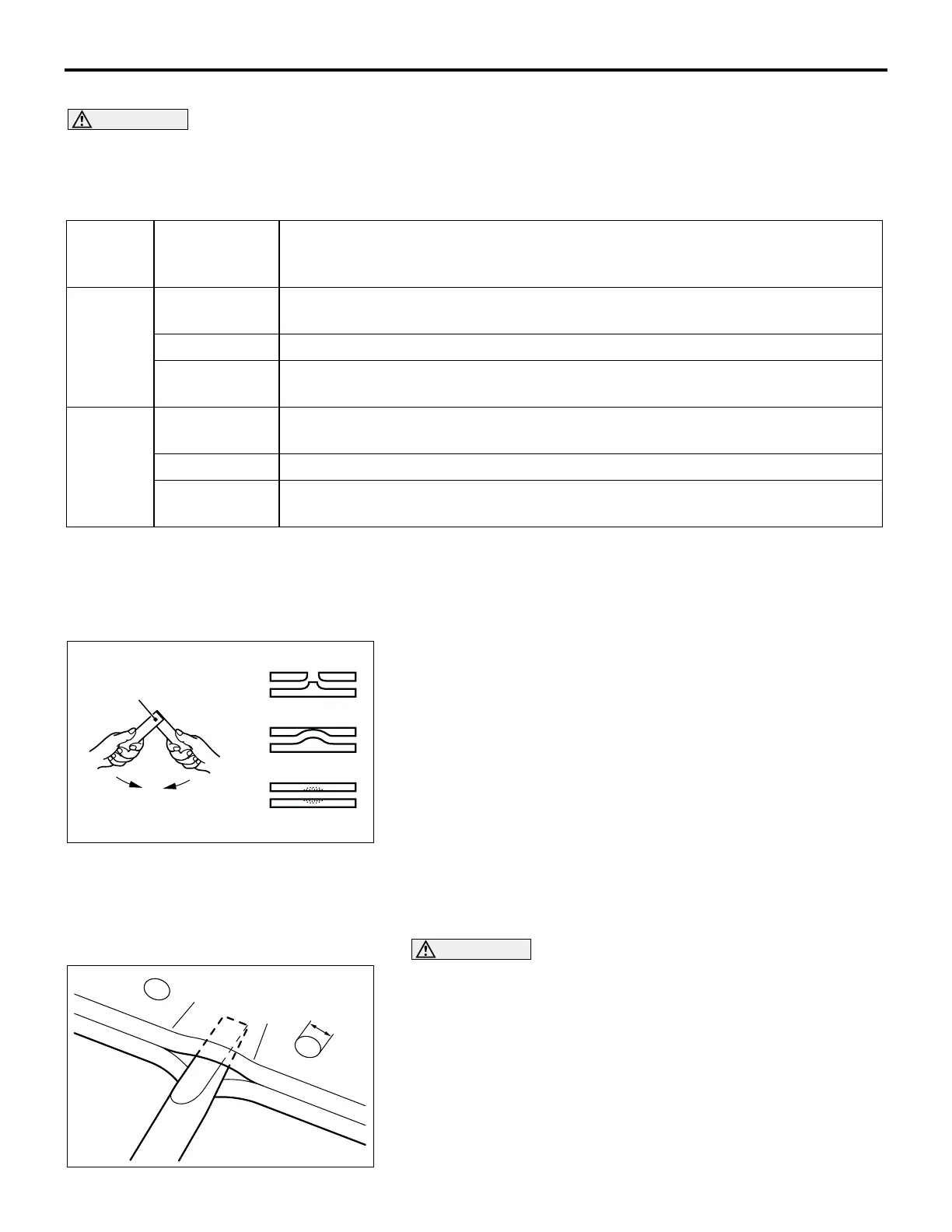

CHECKING NUGGET STRENGTH FOLLOWING SPOT

WELDING

CAUTION

• Stop wedging the tip or the chisel or flat-tipped screw-

driver as soon as the size of the nuggets can be deter-

mined; do not wedge it in more than 30 mm (1.2

inches).

• After checking the nugget diameter, correct the place

where the checking was done.

Wedge the tip of a chisel or flat-tipped (-) screwdriver into the

space between two weld points.

• The nuggets should not break apart.

• The nugget diameter should be 3 mm (0.1 inch) or more.

PANEL

THICKNESS*

[mm (in.)]

NUMBER OF REPAIR WELD (PERCENTAGE OF FACTORY WELD)

SAFETY

EQUIPM

ENT

AREA

0.9 (0.04) or

less

100% Same number as factory welds

1.0 (0.04) 200% Maintain pitch of at least 18 mm (0.7 inch); if not possible, plug weld.

1.2 (0.05) or

more

100% Same number as factory welds; plug welding

OTHER

AREA

0.9 (0.04) or

less

100% Same number as factory welds

1.0 (0.04) 140% Maintain pitch of at least 18 mm (0.7 inch); if not possible, plug weld.

1.2 (0.05) or

more

100% Same number as factory welds; plug welding

AB200032

AB

WELD POINT

1

2

3

AB200033

AB

3 mm (0.1 in)

Loading...

Loading...