WELDING

BASE OF BODY REPAIR

9-10

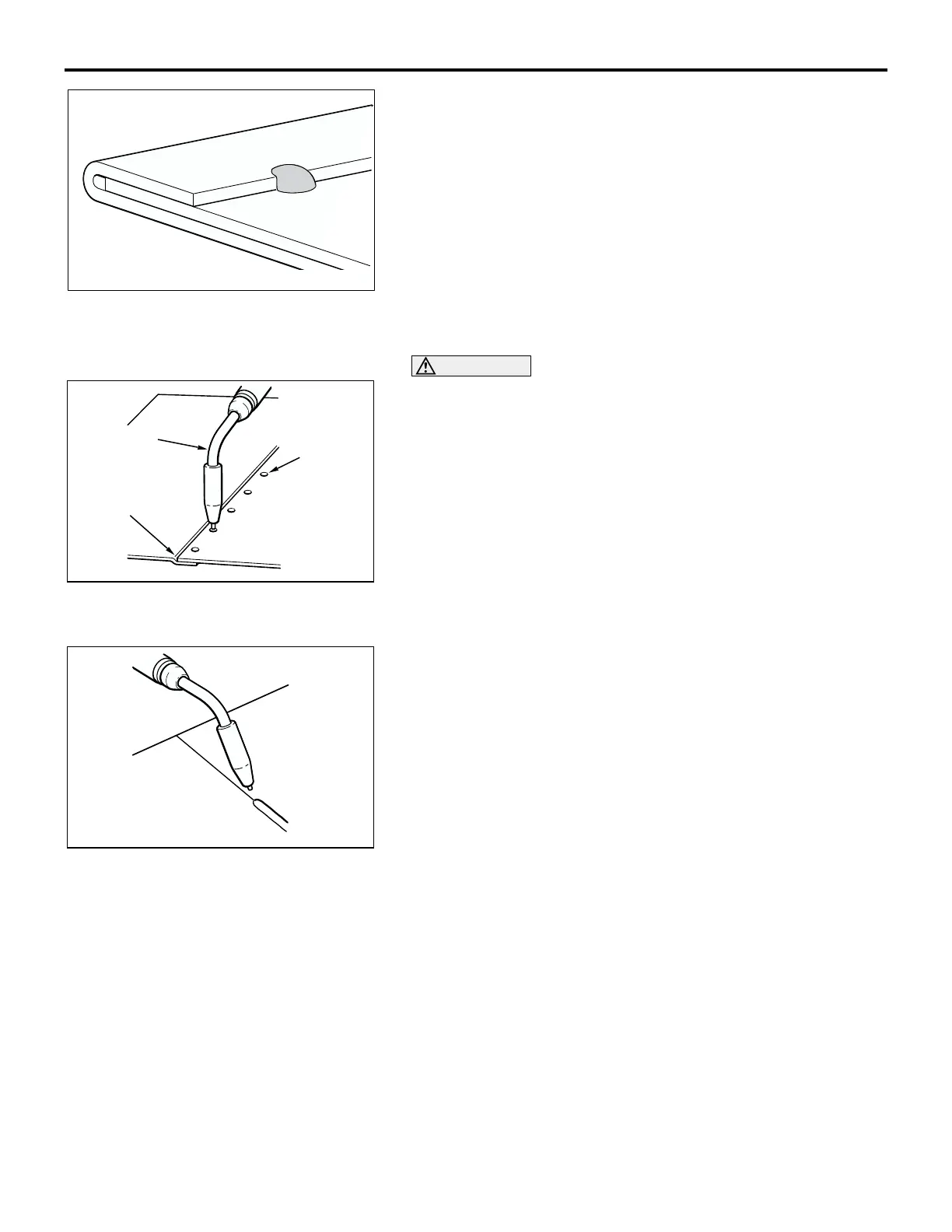

The MIG welding done around the doors, wheelhouse arches,

etc., to prevent the flanges from coming undone after hemming

work is also called MIG spot welding.

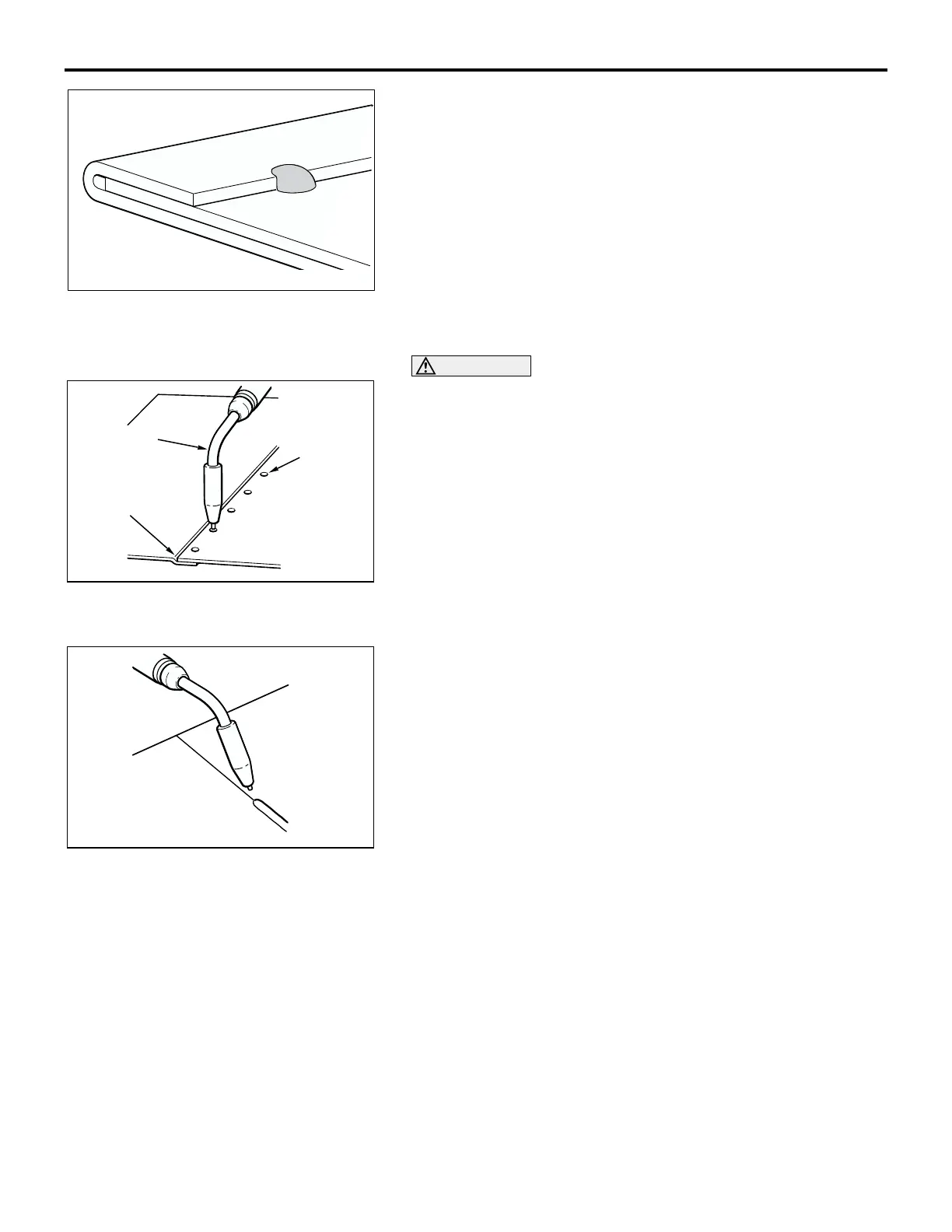

PLUG WELDING

CAUTION

In order to prevent the formation of blowholes, fill in each

hole completely in one pass.Be sure that the two panels

are in perfect contact.Be sure that the penetration goes all

the way to the bottom panel.

Plug welding is done by making holes 5 to 6 mm (0.2 inch) in

diameter in one of the panels to be welded together, positioning

the torch at a right angle to the holes and then filling in the

holes one at a time.

CONTINUOUS WELDING

There are several types of continuous welding: fillet (lap joint)

welding, butt welding, T joint welding, gap welding, etc.; these

are called short-circuit arc welding, and provide a stable arc at

a relatively low current.

.

Torch angle and welding technique

There are two welding techniques: forehand welding and back-

hand welding.

Forehand welding: Penetration is shallow and the bead is flat.

Backhand welding: Penetration is deep and the bead has a

convex shape.

AB200038

AB

AB200040

AB

TORCH

PERFECT

CONTACT

5 TO 6 mm

(0.2 in)

DIAMETER

HOLE

AB200041

Loading...

Loading...