BODY REPAIR

BASE OF BODY REPAIR

9-16

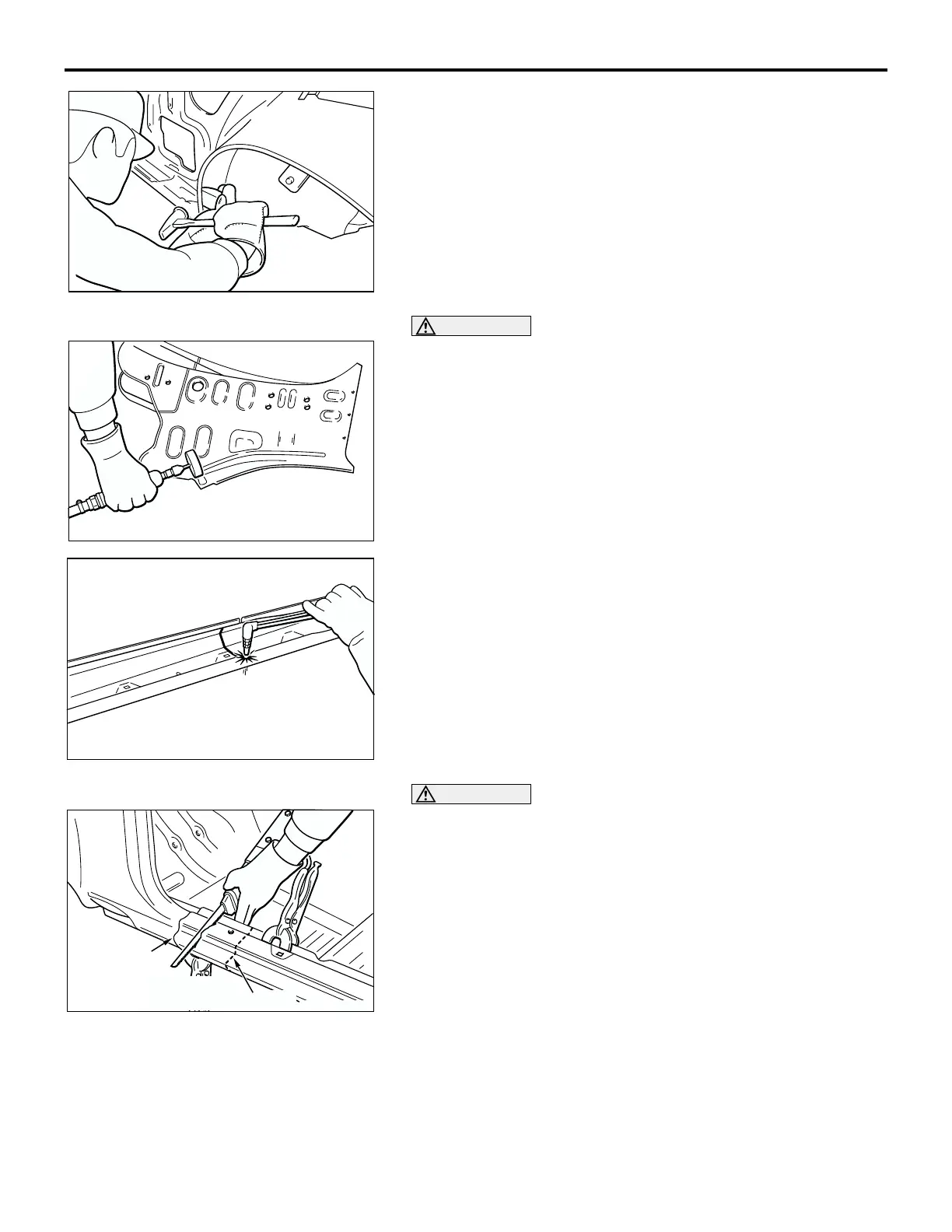

7. Flange correction for spot weld traces

Correct any flanges that become bent or deformed when

spot welds are broken or during other work.

CAUTION

Do not use a flame for paint coat removal because doing

so might damage the paint coat of panels which are not to

be replaced, thus causing corrosion.

8. Removal of the paint coat from new parts and from the

vehicle body

In order to provide for the proper flow of electric current

during spot welding operations, remove the paint coat from

both sides of the new part and the body by using a polisher

wheel or similar tool.

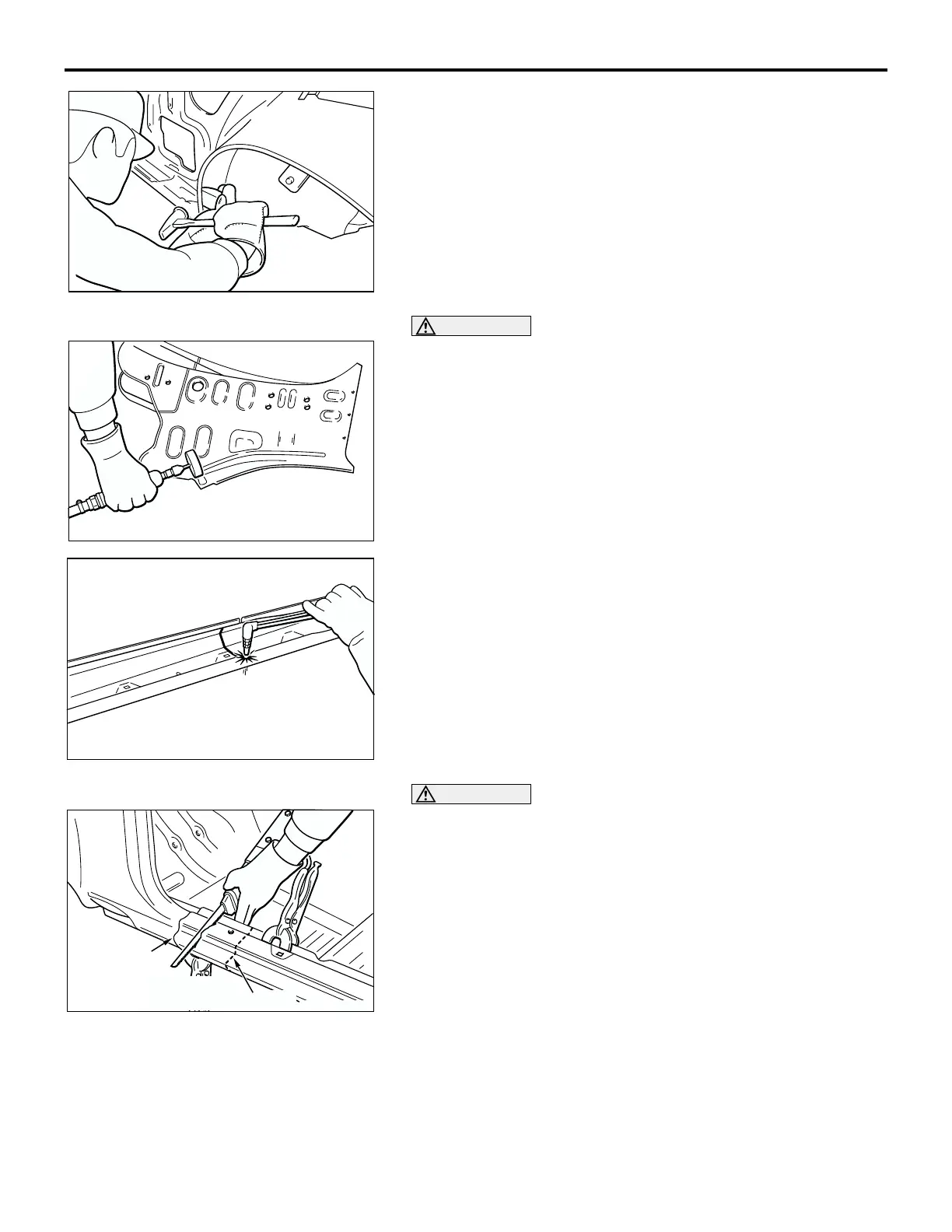

9. Rough cutting of new parts

Cut off the unnecessary portions of new parts. Allow an

overlap of approximately 30 to 50 mm (1.2 to 2.0 inches)

when performing overlap cutting of the pillars, side sills, or

other locations.

CAUTION

Carefully select the location for cutting, taking care not to

cut a reinforcement at the inner side of a pillar, etc. or a

panel that is not to be replaced.

10.Overlap cutting of new parts

For locations in which butt welding is to be done, first

temporarily attach the new parts to the body, and then cut

the two panels simultaneously.

NOTE: If a reinforcement or a panel which is not to be

replaced is cut accidentally, first repair the mistake by weld-

ing before proceeding with the rest of the work.

AB200058

AB200059

AB200060

AB200061

AB

EDGE OF THE

NEW PART

EDGE OF THE

PANEL ON THE BODY

Loading...

Loading...