BODY REPAIR

BASE OF BODY REPAIR

9-17

CAUTION

Perform the operations carefully so that the cut ends fit

together properly.

11.Cutting of new parts by using a measurement marking

If overlap cutting is not possible in a place where butt

welding is to be done, make a measurement marking on the

new part at the exact same measurement which was used

for the cutting of the body panel, and then cut the new part

by using this measurement marking.

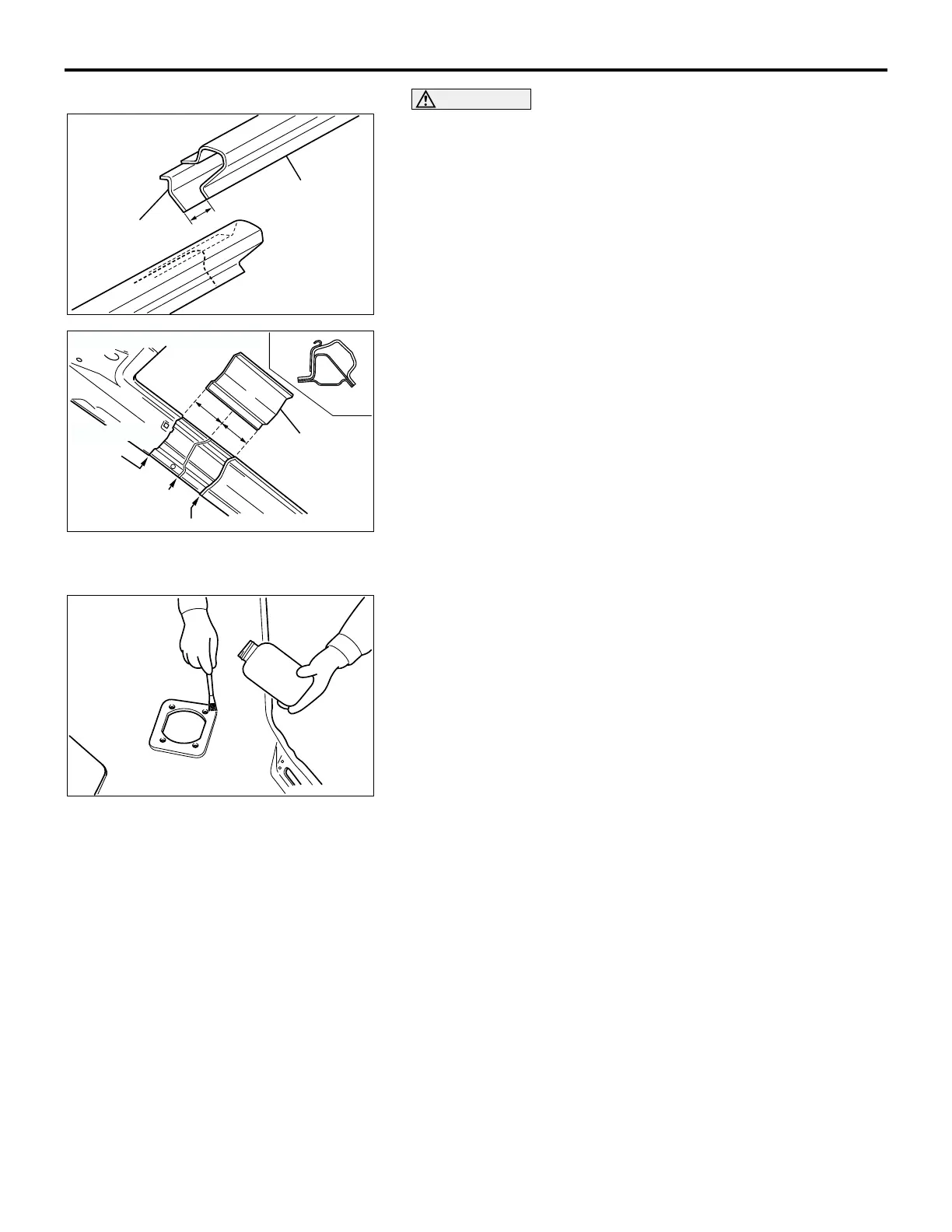

• Two-layer construction

When cutting a front pillar or center pillar which has a two-

layer construction but no reinforcement, make the cutting of

the inner panel and that of the outer panel approximately 50

mm (2.0 inches) apart in order to obtain maximum strength.

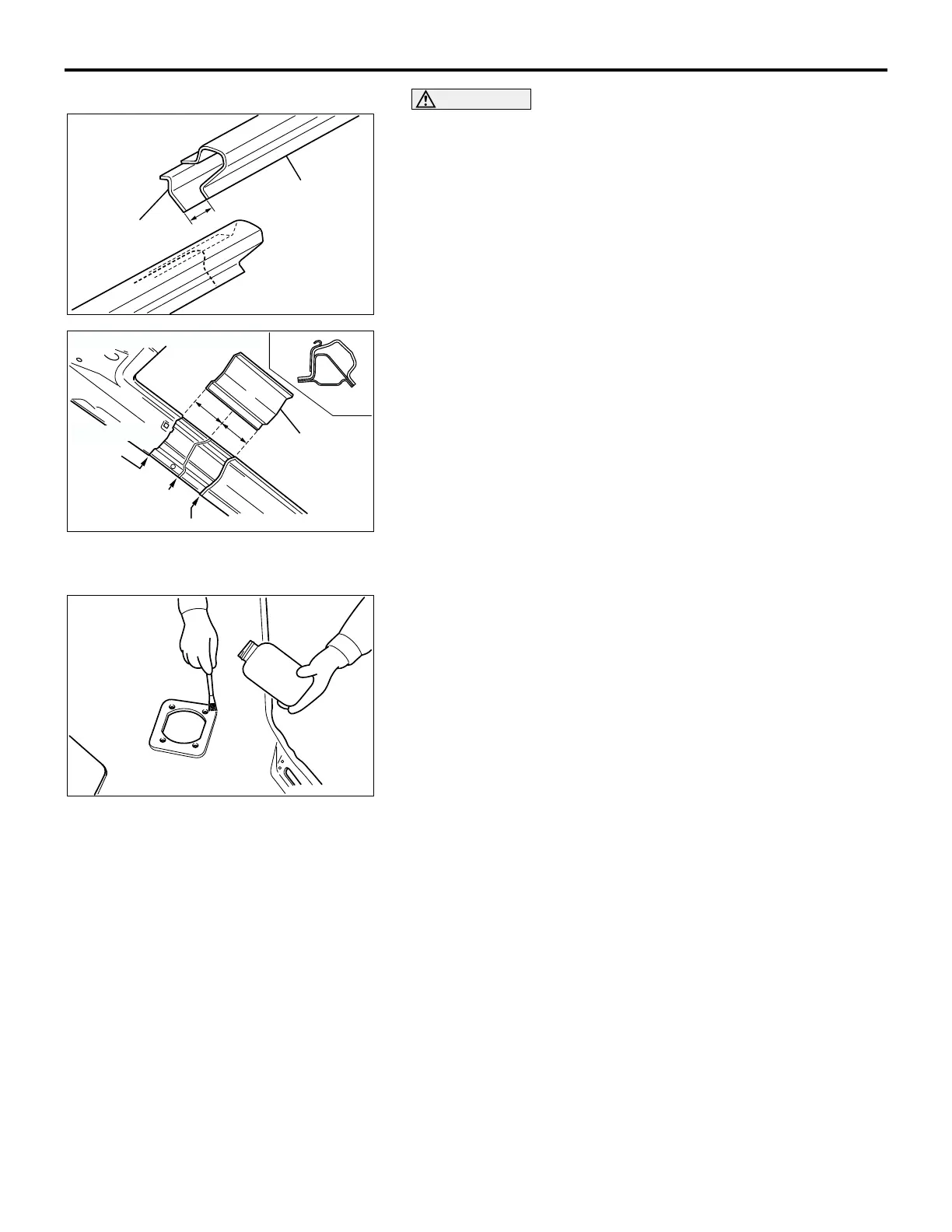

• Three-layer construction

When cutting a front pillar or center pillar which has a three-

layer (including a reinforcement) construction (double-box

construction), cut the outer panel and the reinforcement at

the same position, and don't forget to butt weld the rein-

forcement. If the inner panel is an assembly replacement

part, cut it at two places in order to provide ample working

space for the butt welding of the reinforcement.

12.Application of spot sealer to spot-welded points

Apply an electro-conductive spot sealer to the connecting

surfaces of both the new parts and the vehicle body in order

to provide corrosion protection.

AB200062

AB

OUTER PANEL

APPROX. 50 mm

(2.0 in)

INNER PANEL

TWO-LAYER

CONSTRUCTION

AB200063

AB

INNER PANEL

INNER PANEL

CUT LINE

INNER PANEL CUT LINE

OUTER PANEL

AND REINFORCE-

MENT CUT LINE

THREE-LAYER CONSTRUCTION

AB200064

Loading...

Loading...