BODY REPAIR

BASE OF BODY REPAIR

9-19

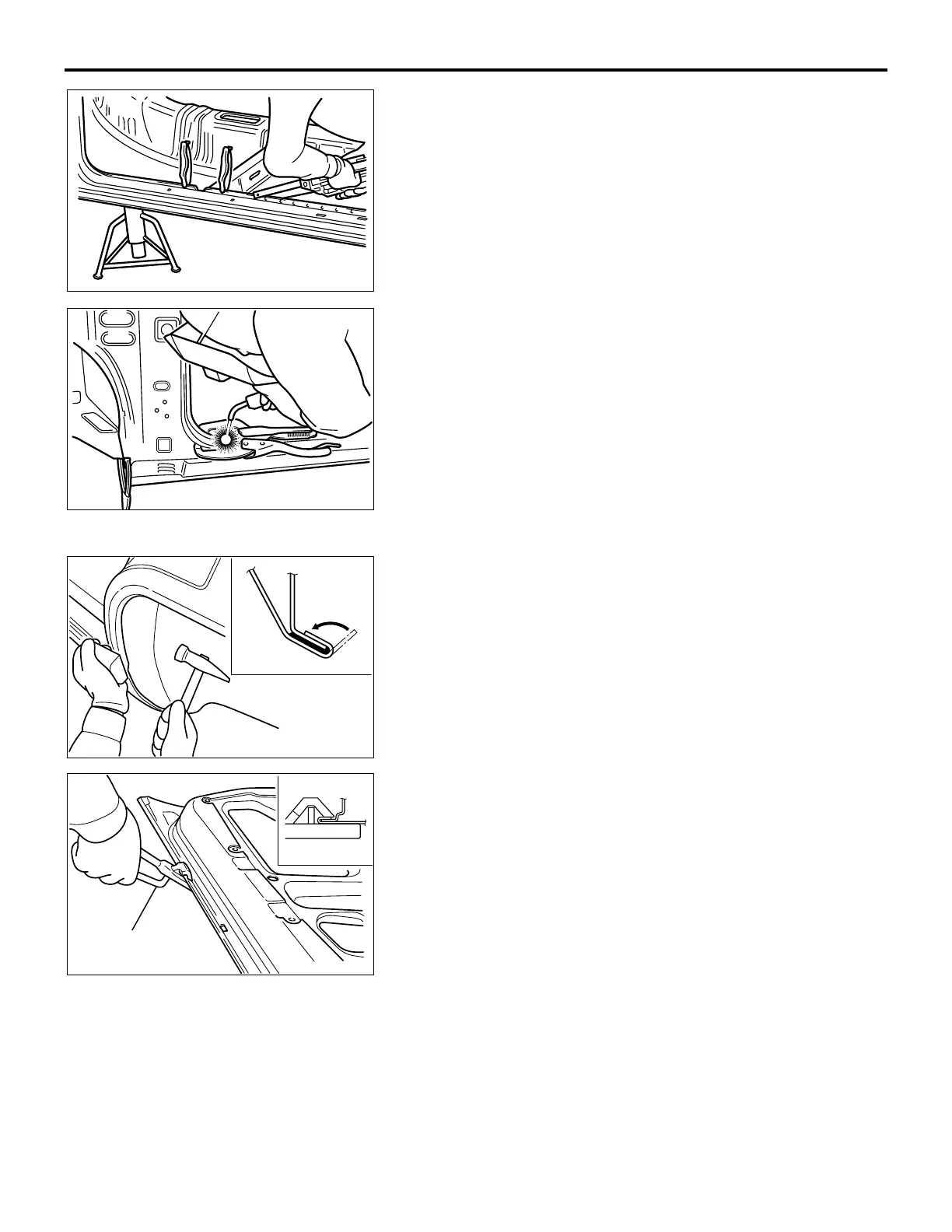

15.Spot welding

When doing spot welding, it is not only important to correctly

position the electrode tips, but also to hold the two panels

securely together with vise-grip pliers or some other type of

clamps, being sure that they are in perfect contact with each

other.

• Be sure that the force applied by the arm is sufficient.

• Use a test piece to check the secondary current and the

current application time of the spot welder, and adjust the

values as appropriate.

16.Plug welding

If spot welds cannot be made, make holes for plug welding

in the new parts, and then MIG weld. Because the quality of

the fusion varies according to the size of the holes, they

should be about 5 to 6 mm (0.2 inch) in diameter. In addition,

be sure the two surfaces are in complete contact with each

other by using vise-grip pliers to securely hold them.

NOTE: Depending on the working conditions, it might also

be necessary to make holes in the panel remaining on the

body

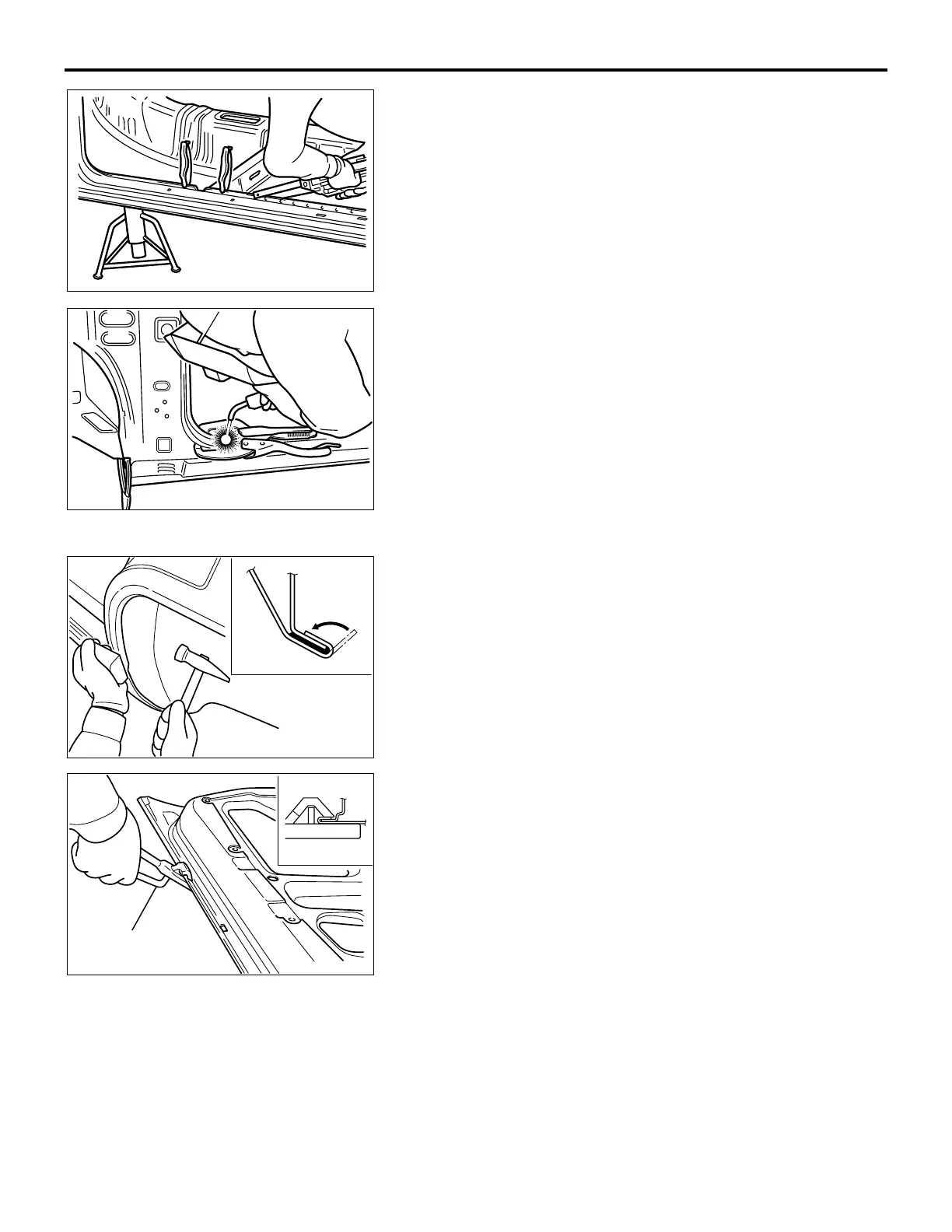

17.Hemming work

(1) If hemming work is to be done for the rear wheel cut line,

the door outer panels, or other parts, use a hammer and

a dolly or a hemming tool to do the work manually.

AB200070

AB200070

AB200071

AB200072

AB

HEMMING TOOL

Loading...

Loading...