ALUMINUM PANEL

WELDED PANEL REPLACEMENT

3-41

Correction of uneven surface

.

Basically, the same as the steel panel. Work with consideration

of characteristics of the aluminum panel.

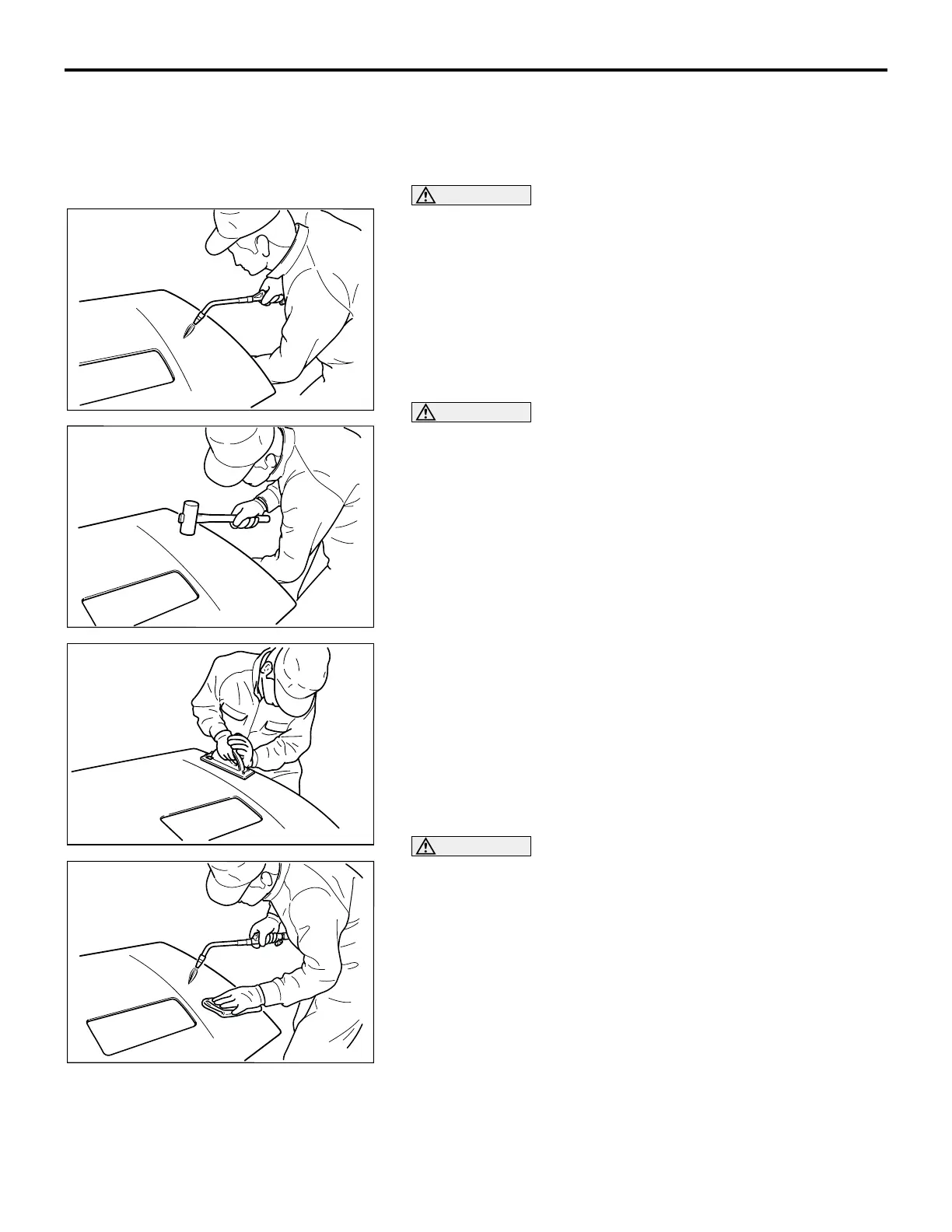

1. Correction of metal sheet:

CAUTION

• Heat-up the panel until you feel heat with a keplar work

glove on the reverse side of the panel.

• Keep moving a burner evenly to prevent one point is

heated.

(1) Heat with the burner.

CAUTION

Try to prevent stretch and hardening, and not to leave any

hammer dent.

(2) Because hammering may stretch the panel, use a mallet

or plastic hammer.

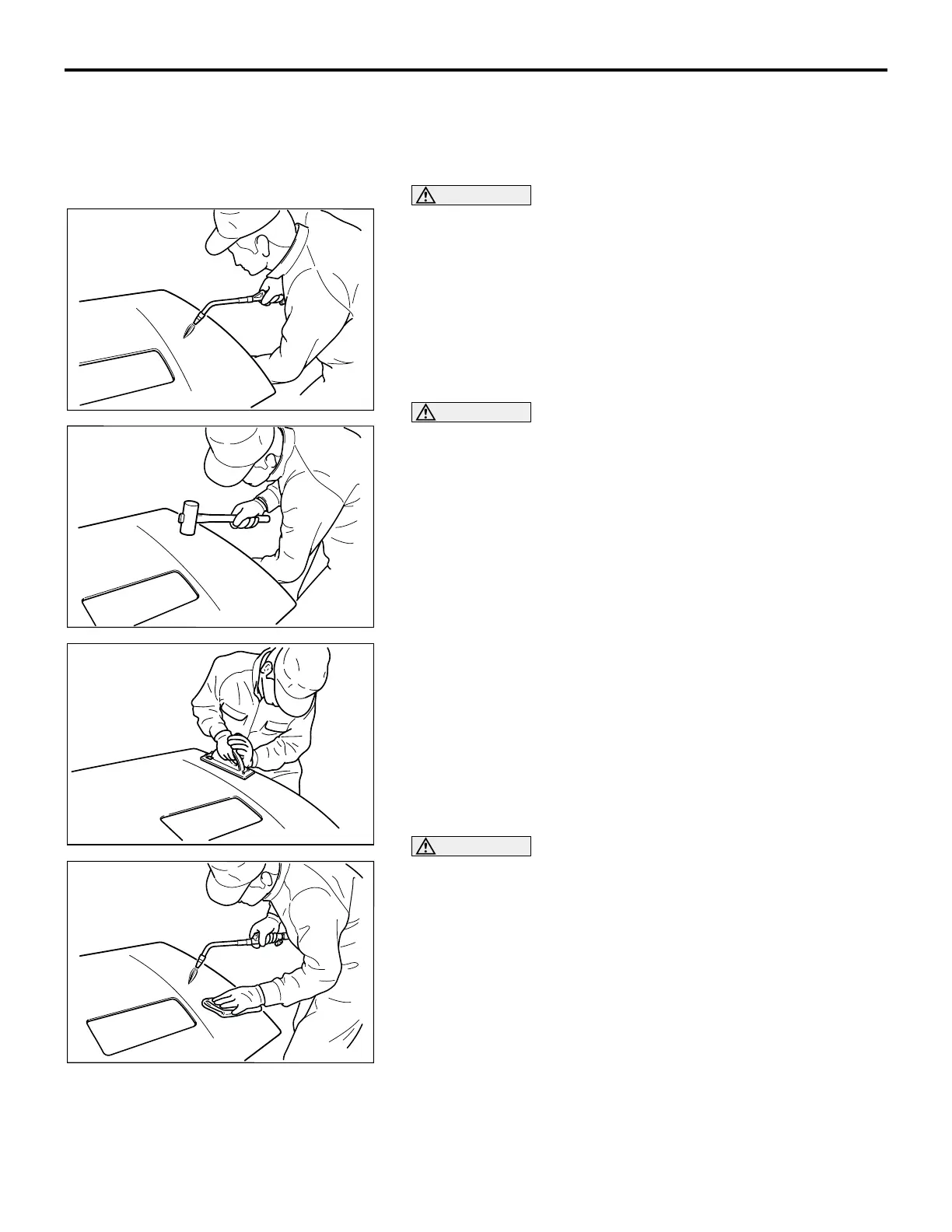

2. Distortion check: Grind the surface with 80 to 120-grit

sandpaper and then check for distortion.

CAUTION

• The surface shall be heated to approximately 250°C

(482°F) when correcting distortion.

• Care must be taken when heating the panel because it

can melt without discoloration.

• Cover the perimeter area with a wet rag or the like to

prevent temperature increase and distortion.

• Do not use a draw hammer designed for steel sheets

because it may cause the panel crack.

3. Straightening: Remove distortion by the draw correction

procedure with a flattening hammer and a burner.

AB202119

AB202120

AB202113

AB202116

Loading...

Loading...