ALUMINUM PANEL

WELDED PANEL REPLACEMENT

3-43

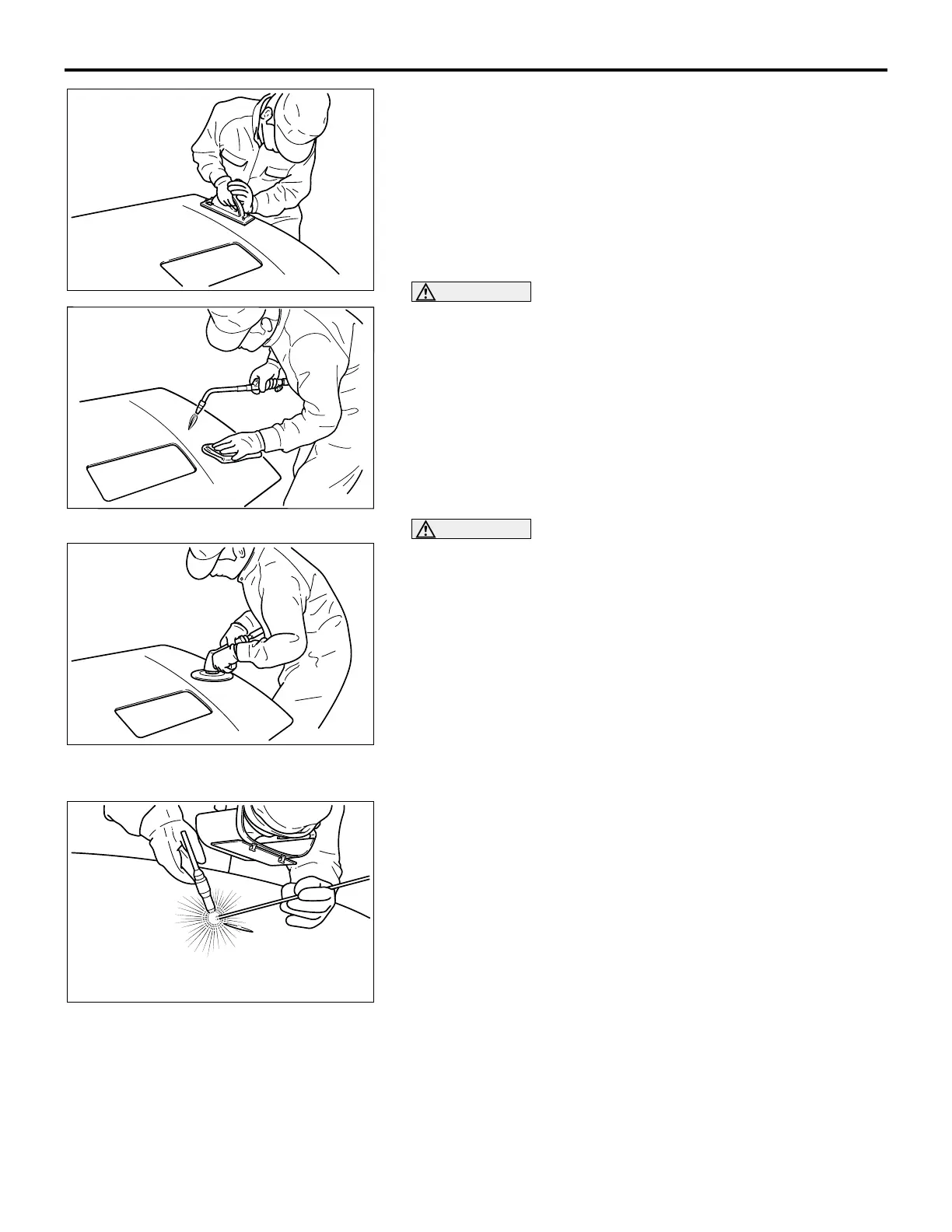

4. Check for distortion: Grind the surface with 80 to 120-grit

sandpaper and then check for distortion.

CAUTION

• The surface shall be heated to approximately 250°C

(482°F) when correcting distortion.

• Care must be taken when heating the panel because it

can melt without discoloration.

• Cover the perimeter area with a wet rag or the like to

prevent temperature increase and distortion.

• Do not use a draw hammer designed for steel sheets

because it may cause the panel crack.

5. Straightening: Remove distortion by the draw correction

procedure with a flattening hammer and a burner.

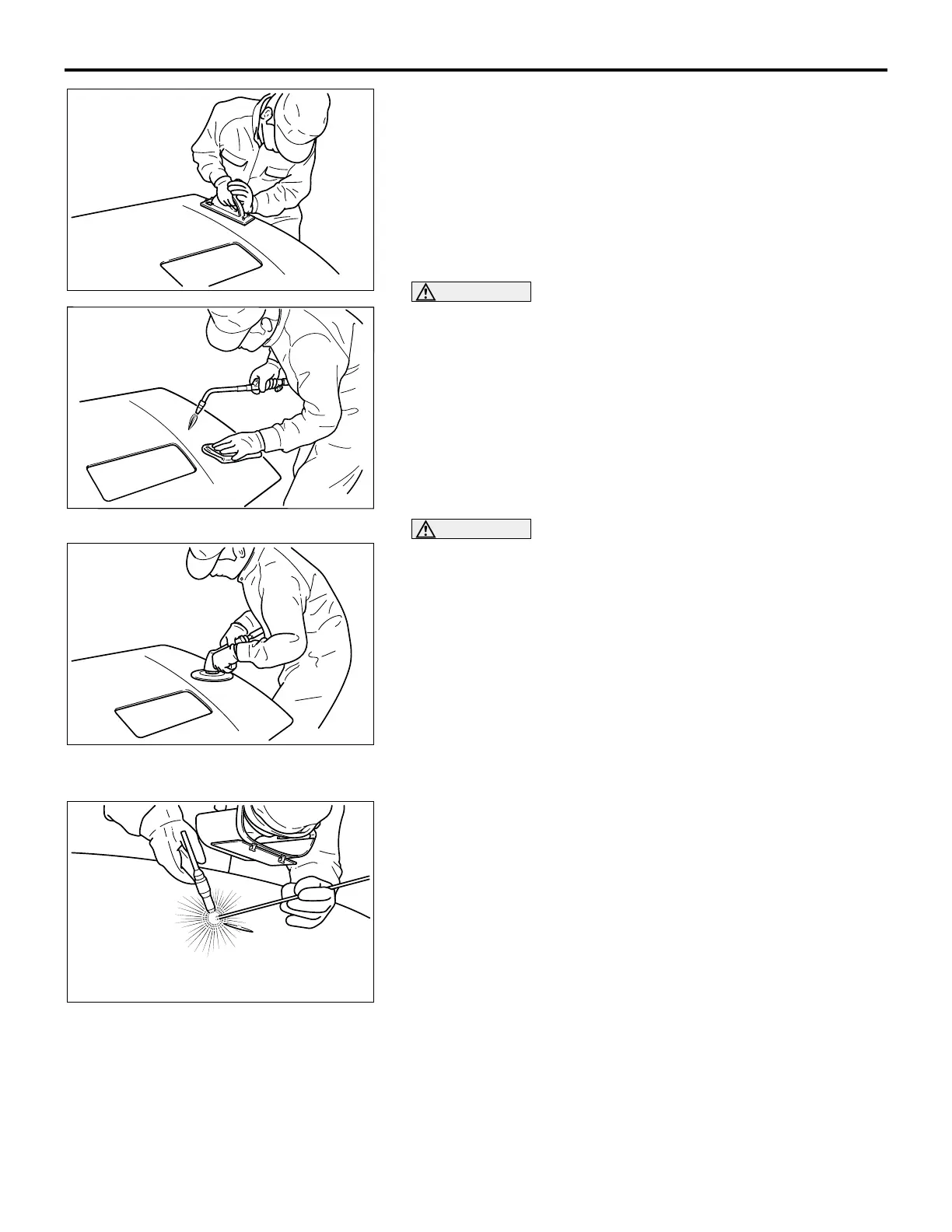

CAUTION

Remove any spark spot or carbon residue on the surface

by a stainless steel wire brush, because they will cause

improper painting in the following process.

6. Finishing: Finish the surface with a 100 to 120-grit disk

sander.

.

TIG welding

Welding procedure is the same as MIG welding, however, it

uses a welding rod instead of electrode wire.

Diameter of welding rod: 1.6 mm (0.063 in.)

AB202113

AB202116

AB202109

AB202108

Loading...

Loading...