7

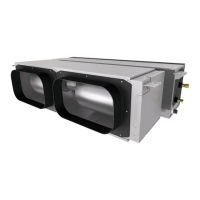

6. Refrigerant piping work

6.1. Refrigerant pipe

[Fig. 6-1]

øB

øA

ⓐ

ⓑ

ⓐ

Indoor unit

ⓑ

Outdoor unit

Model A B

PEA-M100, 125, 140 ø15.88 ø9.52

Refer to the Instruction Manual that came with the outdoor unit for the restrictions on

theheightdierencebetweenunitsandfortheamountofadditionalrefrigerant

charge.

Avoid the following places for installation where air conditioner trouble is liable to

occur.

• Where there is too much oil such as for machine or cooking.

• Salty environment as seaside areas.

• Hot-spring areas.

• Wheresuldegasexists.

• Other special atmospheric areas.

• Thisunithasaredconnectionsonbothindoorandoutdoorsides.[Fig. 6-1]

• Insulate both refrigerant and drainage piping completely to prevent condensation.

Piping preparation

• Refrigerant pipes of 3, 5, 7, 10 and 15 m are available as optional items.

(1)Tablebelowshowsthespecicationsofpipescommerciallyavailable.

Model Pipe

Outside diameter

Min wall

thickness

Insulation

thickness

Insulation

material

mm inch

PEA-

M100,

125, 140

For liquid 9.52 3/8 0.8 mm 8 mm

Heat resisting

foam plastic

0.045specic

gravity

For gas 15.88 5/8 1.0 mm 8 mm

(2)Ensurethatthe2refrigerantpipesarewellinsulatedtopreventcondensation.

(3)Refrigerantpipebendingradiusmustbe10cmormore.

Caution:

Using careful insulation of specied thickness. Excessive thickness prevents

storage behind the indoor unit and smaller thickness causes dew drippage.

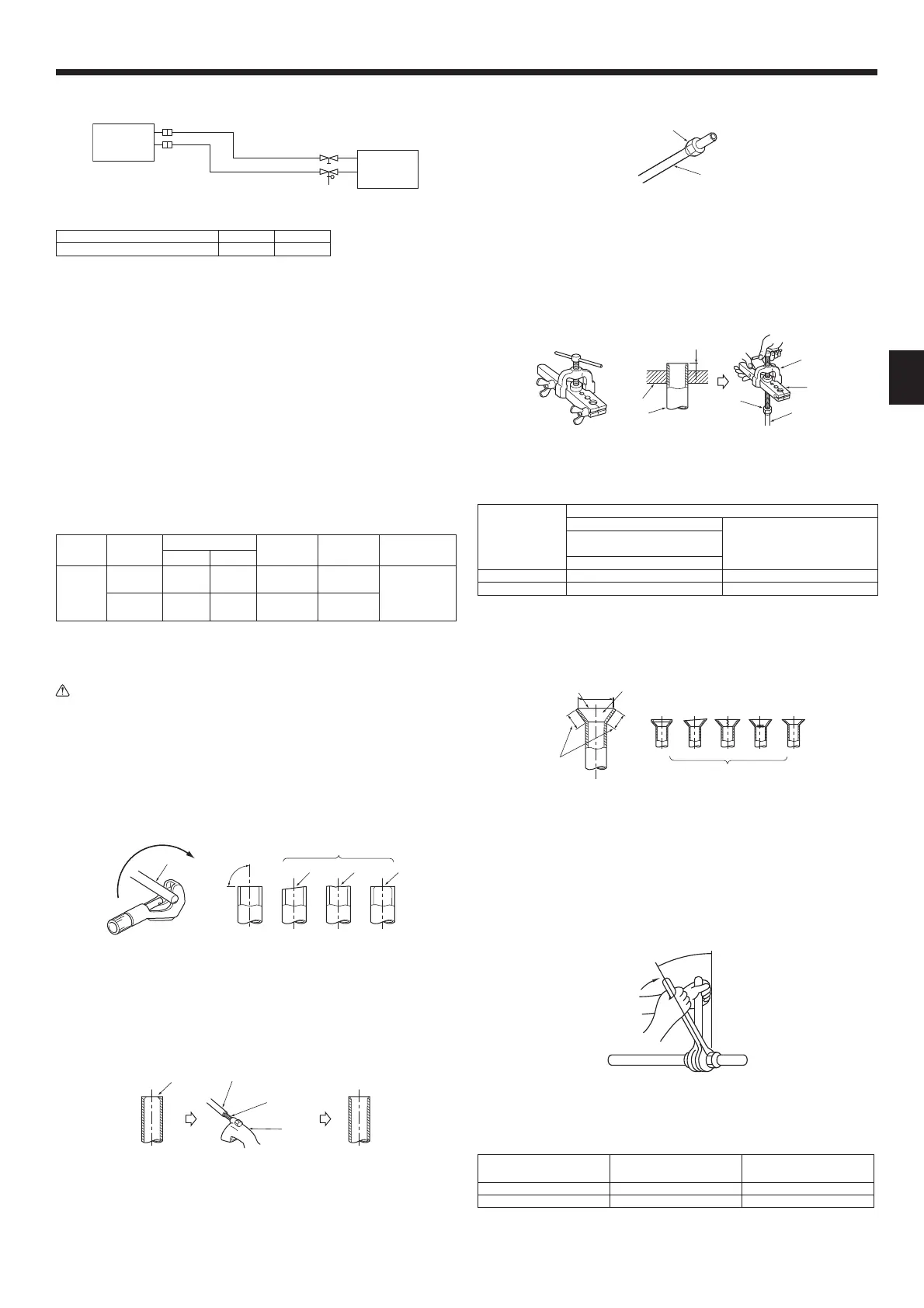

6.2. Flaring work

• Maincauseofgasleakageisdefectinaringwork.

Carryoutcorrectaringworkinthefollowingprocedure.

6.2.1. Pipe cutting

[Fig. 6-2-1]

ⓐ

ⓓ

ⓔ

90°

ⓐ

Copper tubes

ⓓ

Tilted

ⓑ

Good

ⓔ

Uneven

ⓒ

No good

ⓕ

Burred

• Using a pipe cutter cut the copper tube correctly.

6.2.2. Burrs removal

[Fig. 6-2-2]

ⓓ

ⓒ

ⓐ

ⓐ

Burr

ⓒ

Spare reamer

ⓑ

Copper tube/pipe

ⓓ

Pipe cutter

• Completely remove all burrs from the cut cross section of pipe/tube.

• Put the end of the copper tube/pipe to downward direction as you remove burrs

in order to avoid burrs drop in the tubing.

6.2.3. Putting nut on

[Fig. 6-2-3]

ⓐ

Flare nut

ⓑ

Copper tube

• Remove arenuts attached to indoor and outdoor unit, then put them on pipe/

tube having completed burr removal.

(notpossibletoputthemonafteraringwork)

• Usethearenutincludedwiththisindoorunit.

6.2.4. Flaring work

[Fig. 6-2-4]

ⓔ

ⓑ

ⓒ

ⓓ

ⓒ

ⓐ

Flaring tool

ⓓ

Flare nut

ⓑ

Die

ⓔ

Yoke

ⓒ

Copper tube

• Carryoutaringworkusingaringtool.

Pipe diameter

(mm)

Dimension

A(mm)

B(mm)

When the tool for R32/R410A

is used

Clutch type

9.52 0 - 0.5 13.2

15.88 0 - 0.5 19.7

Firmly hold copper tube in a die in the dimension shown in the table at above.

• Whenreconnectingthedetachedrefrigerantpipes,makesuretoarethemagain.

6.2.5. Check

[Fig. 6-2-5]

ⓓ ⓔ ⓕ ⓖ ⓗ

ⓐ

Smooth all around

ⓕ

Scratchonaredplane

ⓑ

Inside is shining without any scratches

ⓖ

Cracked

ⓒ

Even length all around

ⓗ

Uneven

ⓓ

Too much

ⓘ

Bad examples

ⓔ

Tilted

• Comparethearedworkwithagureinrightsidehand.

•

Ifareisnotedtobedefective,cutothearedsectionanddoaringworkagain.

6.3. Pipe connection

[Fig. 6-3-1]

• Apply a thin coat of refrigeration oil on the seat surface of pipe.

• Forconnectionrstalignthecenter,thentightentherst3to4turnsofarenut.

• Use tightening torque table below as a guideline for indoor unit side union joint

section,andtightenusingtwowrenches.Excessivetighteningdamagestheare

section.

Copper pipe O.D.

(mm)

Flare nut O.D.

(mm)

Tightening torque

(N·m)

ø9.52 22 34 - 42

ø15.88 29 68 - 82

+0

-0.4

Loading...

Loading...