16

9. Test run

• If the unit cannot be operated properly after the above test run has been performed, refer to the following table to remove the cause.

Symptom

Cause

Wired remote controller LED1,2(PCBinoutdoorunit)

PLEASE WAIT

For about 2 minutes

following power-on

After LED 1, 2 are lighted, LED 2 is turned

o,thenonlyLED1islighted.(Correct

operation)

• For about 2 minutes after power-on, operation of the

remote controller is not possible due to system start-up.

(Correctoperation)

PLEASE WAIT

→

Error code

After about 2

minutes has expired

following power-on

Only LED 1 is lighted.

→

LED 1, 2 blink.

• Connector for the outdoor unit’s protection device is not

connected.

• Reverse or open phase wiring for the outdoor unit’s power

terminalblock(L1,L2,L3)

Display messages do not appear

even when operation switch is

turned ON (operation lamp does

notlightup).

Only LED 1 is lighted.

→

LED 1, 2 blinks

twice, LED 2 blinks once.

• Incorrect wiring between indoor and outdoor units (incorrect

polarityofS1,S2,S3)

• Remote controller wire short

On the wireless remote controller with conditions above, following phenomena takes place.

• No signals from the remote controller are accepted.

• OPE lamp is blinking.

• The buzzer makes a short ping sound.

Note:

Operation is not possible for about 30 seconds after cancellation of function selection. (Correct operation)

FordescriptionofeachLED(LED1,2,3)providedontheindoorcontroller,refertothefollowingtable.

LED1(powerformicrocomputer) Indicates whether control power is supplied. Make sure that this LED is always lit.

LED2(powerforremotecontroller) Indicates whether power is supplied to the remote controller. This LED lights only in the case of

the indoor unit which is connected to the outdoor unit refrigerant address “0”.

LED3(communicationbetweenindoorandoutdoorunits)

Indicates state of communication between the indoor and outdoor units. Make sure that this LED is

always blinking.

9.4. AUTO RESTART FUNCTION

Indoor controller board

This model is equipped with the AUTO RESTART FUNCTION.

When the indoor unit is controlled with the remote controller, the operation mode, set temperature, and the fan speed are memorized by the indoor controller board.

The auto restart function sets to work the moment the power has restored after power failure, then, the unit will restart automatically.

SettheAUTORESTARTFUNCTIONusingtheremotecontroller.(Modeno.01)

10. Maintenance

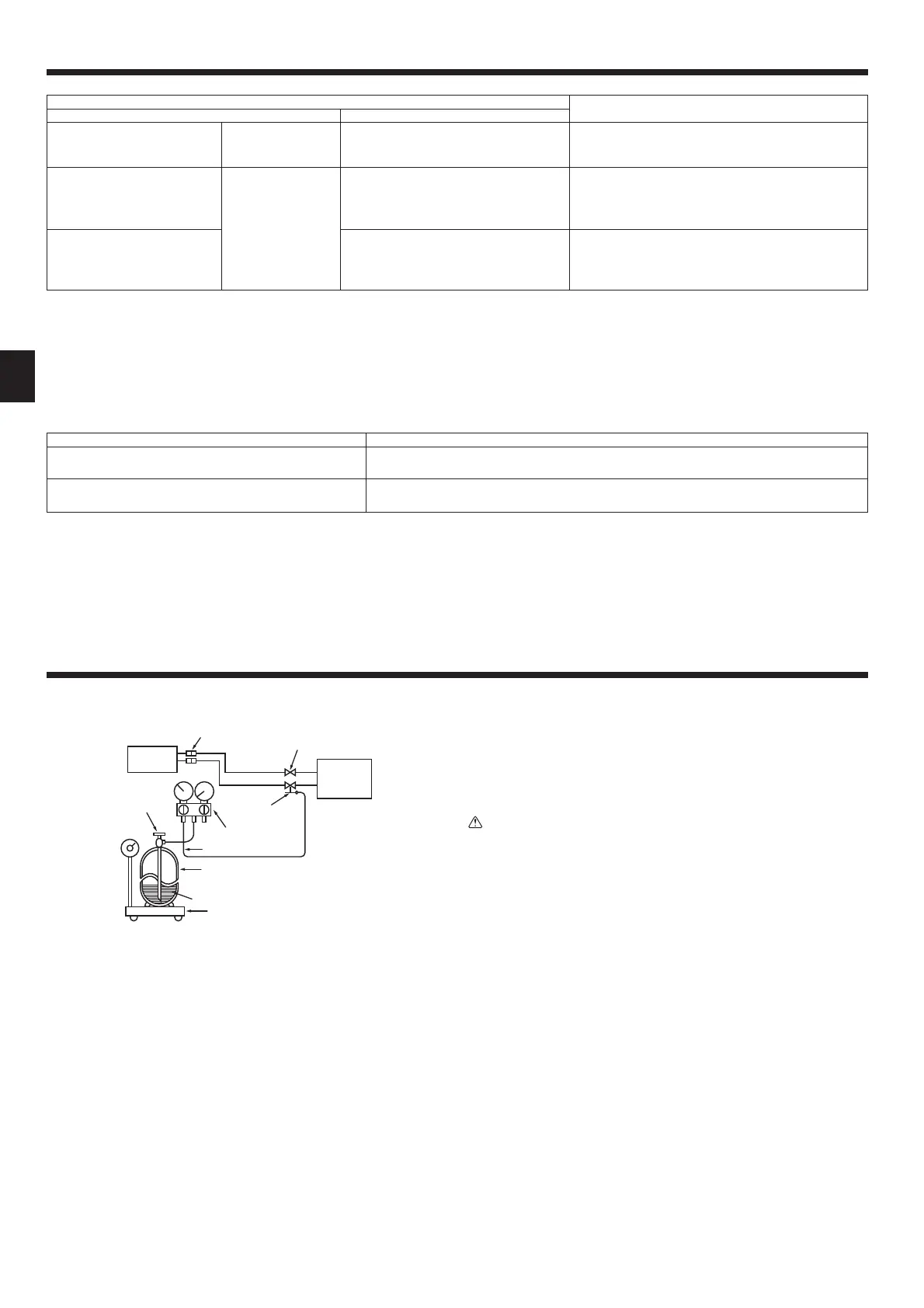

10.1. Gas charge

[Fig. 10-1]

Ⓐ

Ⓖ

Ⓗ

Ⓚ

Ⓛ

Ⓜ

Ⓘ

Ⓙ

Ⓒ

Ⓓ

Ⓔ

Ⓕ

Ⓐ

Indoor unit

Ⓑ

Union

Ⓒ

Liquid pipe

Ⓓ

Gas pipe

Ⓔ

Stop valve

Ⓕ

Outdoor unit

Ⓖ

Refrigerant gas cylinder operating valve

Ⓗ

Refrigerant gas cylinder for R32/R410A with siphon

Ⓘ

Refrigerant(liquid)

Ⓙ

Electronic scale for refrigerant charging

Ⓚ

Chargehose(forR32/R410A)

Ⓛ

Gaugemanifoldvalve(forR32/R410A)

Ⓜ

Service port

1. Connect gas cylinder to the service port of stop valve (3-way).

2. Execute air purge of the pipe (or hose) coming from refrigerant gas

cylinder.

3. Replenish specified amount of refrigerant, while running the air

conditioner for cooling.

Note:

Incaseofaddingrefrigerant,complywiththequantityspeciedfortherefrigerating

cycle.

Caution:

• Do not discharge the refrigerant into the atmosphere.

Take care not to discharge refrigerant into the atmosphere during

installation, reinstallation, or repairs to the refrigerant circuit.

• For additional charging, charge the refrigerant from liquid phase of the gas

cylinder.

If the refrigerant is charged from the gas phase, composition change may

occur in the refrigerant inside the cylinder and the outdoor unit. In this

case, ability of the refrigerating cycle decreases or normal operation can be

impossible. However, charging the liquid refrigerant all at once may cause

the compressor to be locked. Thus, charge the refrigerant slowly.

To maintain the high pressure of the gas cylinder, warm the gas cylinder with warm

water(under40°C)duringcoldseason.Butneverusenakedreorsteam.

Loading...

Loading...