Removal steps

>>E<<

1. Crankshaft bearing cap bolt

>>E<<

2. Crankshaft bearing cap

>>D<<

3. Crankshaft bearing lower

<<A>>

4. Crankshaft

>>C<<

5. Crankshaft bearing upper

>>B<<

6. Thrust bearing

>>A<<

7. Crankshaft sensing ring

8. Cylinder block

CRANKSHAFT AND CYLINDER BLOCK

ENGINE OVERHAUL

11B-60

REMOVAL SERVICE POINT

<<A>> CRANKSHAFT REMOVAL

When temporarily placing the crankshaft with the

crankshaft sensing ring attached, temporarily place it

on a V-block to prevent teeth of the sensing ring from

deforming.

NOTE: If a tooth bends, be sure to replace the crank-

shaft sensing ring with a new one.

INSTALLATION SERVICE POINTS

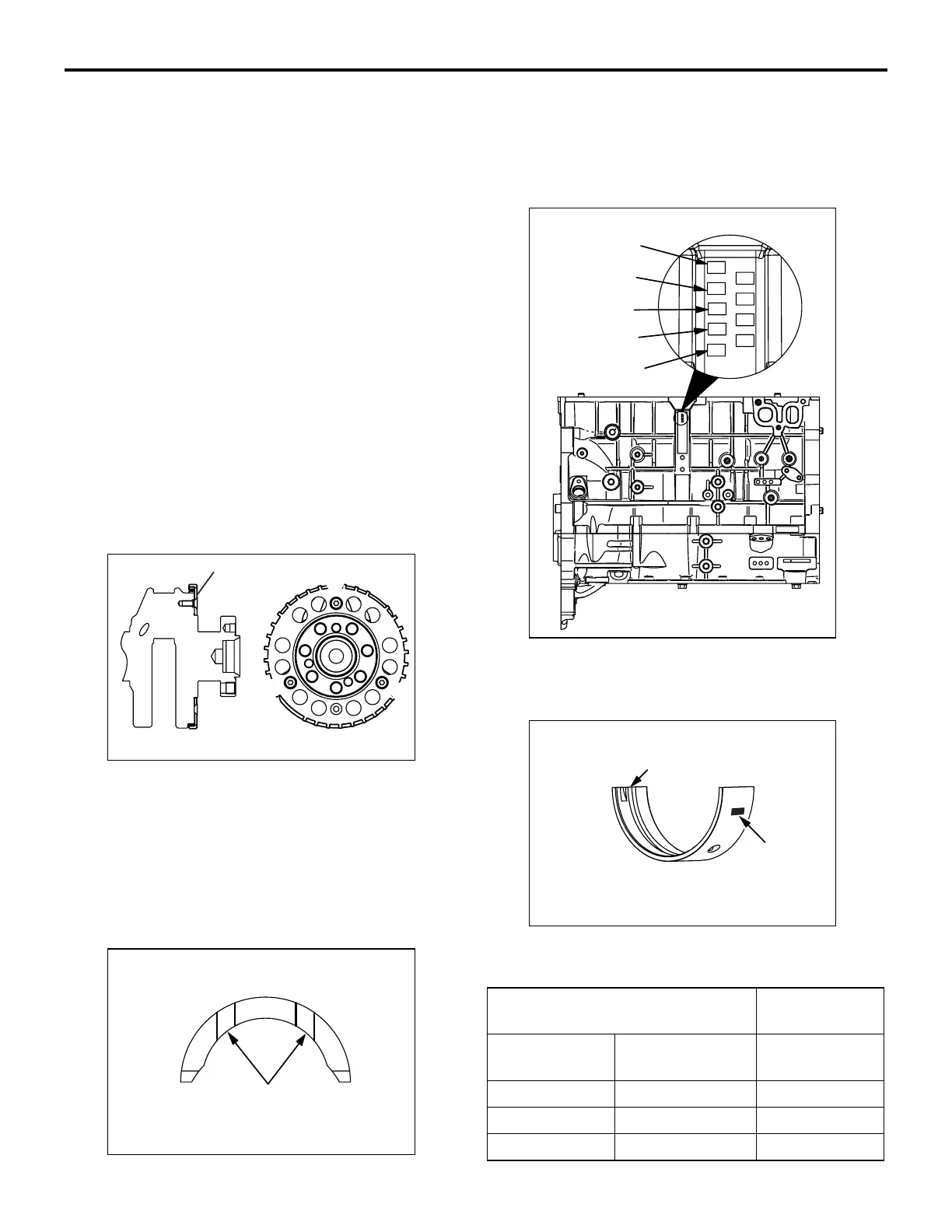

>>A<< CRANKSHAFT SENSING RING

INSTALLATION

AKB00121

AC

1

2

3

Crankshaft sensing ring

Tighten crankshaft sensing ring bolts to the torque of

11

± 1 N⋅m in the tightening order shown in the illus-

tration.

>>B<< THRUST BEARING INSTALLATION

1. Install the thrust bearing on the No. 3 bearing on

the cylinder block side. Application of engine oil

makes the installation easy.

AK502394

Groove

AD

2. Install the thrust bearing so that the grooved side

is on the crankshaft weight side.

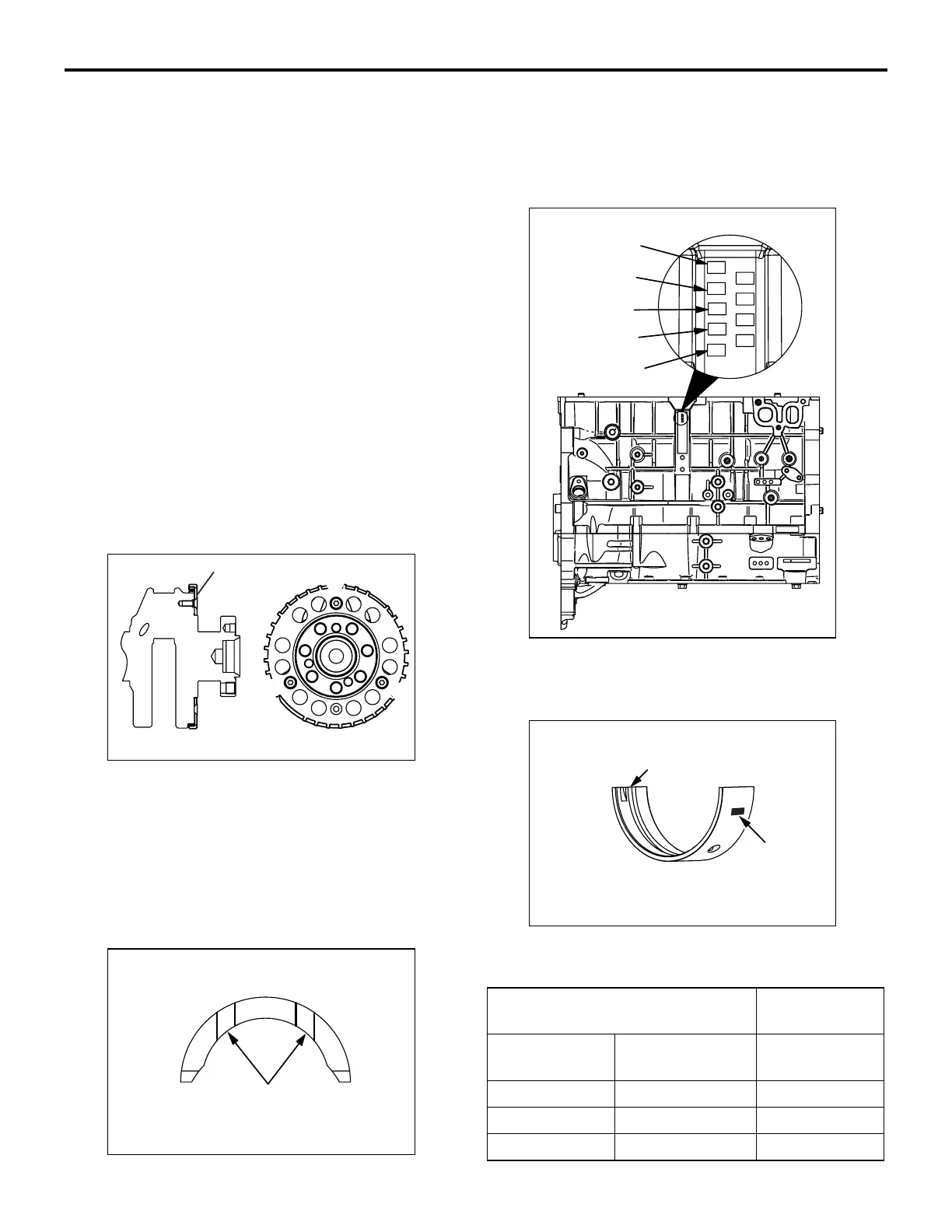

>>C<< CRANKSHAFT BEARING UPPER

INSTALLATION

J2

J3

J4

J5

J1

AK502530

No.1

No.2

No.3

No.4

No.5

AC

1. When replacing the crankshaft bearing upper,

select a bearing with the size corresponding to the

cylinder block journal diameter in the table below.

AK502396

Groove

AF

Identification

mark

2. The crankshaft bearing upper has an identification

mark at the illustrated position.

Cylinder block Crankshaft

bearing

Identification

mark

Journal

diameter mm

Identification

mark

1 56.000 − 56.006 1

2 56.006 − 56.012 2

3 56.012 − 56.018 3

3. Install the selected crankshaft bearing upper.

Loading...

Loading...