Appendix - 83

MELSEC-Q

APPENDICES

MOVEMENT AMOUNT PER PULSE

When using mm, inch, or degree units, the

movement amount is calculated and output

from the machine side showing how much the

motor shaft moves per pulse. Equivalent to the

positioning detection units. Positioning

accuracy in smaller units is not possible.

On the motor side, the movement amount per

axis rotation is normally designed as a

reference, so it is calculated as follows.

Movement amount per pulse =

P rate

No. of pulses per

encoder rotation

Movement amount

per rotation

Amount the motor moves (travel) per pulse.

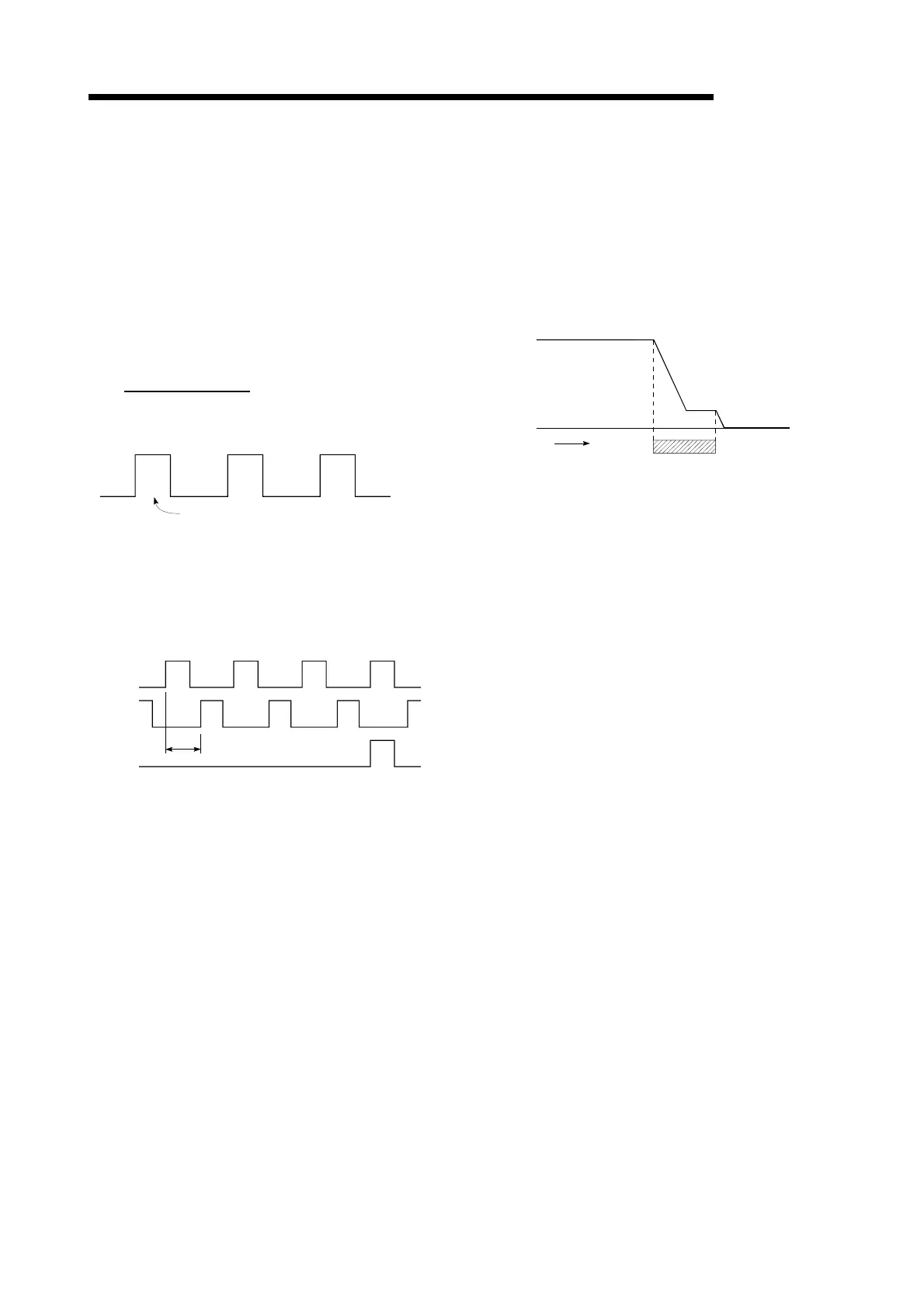

MULTI-PHASE PULSE

A combination of pulses in which 2 or more

phases differ.

2-phase pulses, etc.

phase

Phase difference

B phase

phase

(ZERO signal)

MULTIPLYING RATE SETTING

The P rate. Refer to the term "P RATE".

NC LANGUAGE (Numerical Control

Language)

This is the language punched into the paper

tape that instructs the machining to the NC

module.

The NC language consists of EIA codes (EIA

language), ISO codes (ISO standards), and

JIS codes (JIS standards).

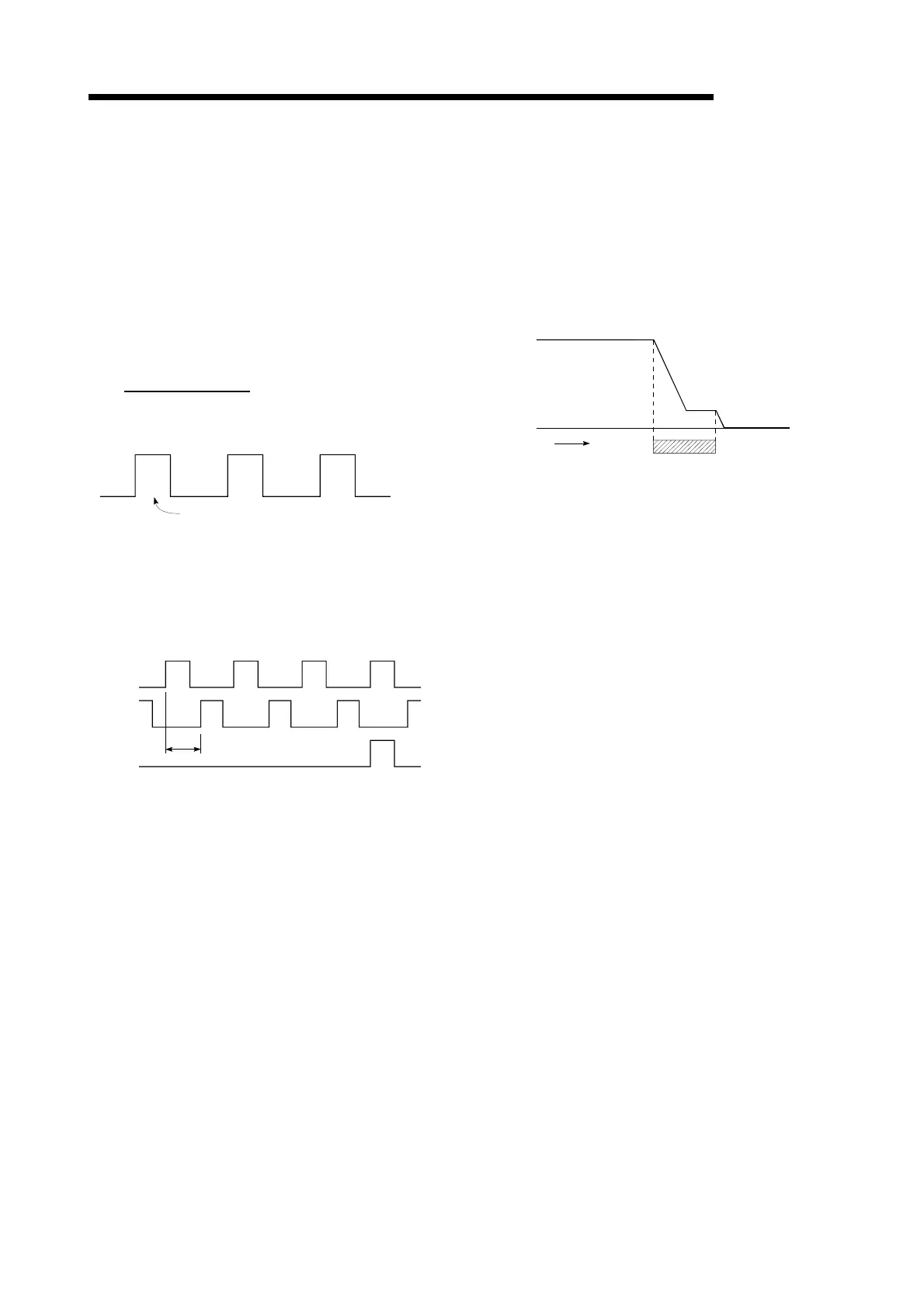

NEAR-POINT DOG

This is a limit switch placed before the OP.

When this switch turns ON, the feedrate is

changed to the creep speed. Because of that,

the time that this switch is ON must be long

enough to allow for the time required for

deceleration from the feedrate to the creep

speed.

ON OFF

Feedrate

Creep speed

Time

Near-point dog

NEW CURRENT VALUE (CURRENT VALUE

CHANGING)

The QD75 has no way of knowing the current

value when the machine is assembled and the

positioning module is connected, so this

function is used to teach it a temporary

approximate value as the current value. This

function can also be used to write a temporary

current value when the current value has been

lost due to accidents, etc. If an OPR is carried

out after that, the positioning module will

recognize the zero point.

In fixed-feed, etc., rewriting the current value

to 0 after the fixed-feed will keep the

accumulated value from being affected by the

upper stroke limit. The current value can be

changed during a positioning stop.

Loading...

Loading...