22

STEP CUTS

A Step Cut is performed when a series of small cuts of increasing depth are used to complete a single

cut. Step Cuts are used for large objects or for hard objects such as Firebrick and Pavers.

Cut in smooth even strokes;

do not force the saw to cut.

MK-2000 ELECTRIC SAW ADJUSTMENT & OPERATION

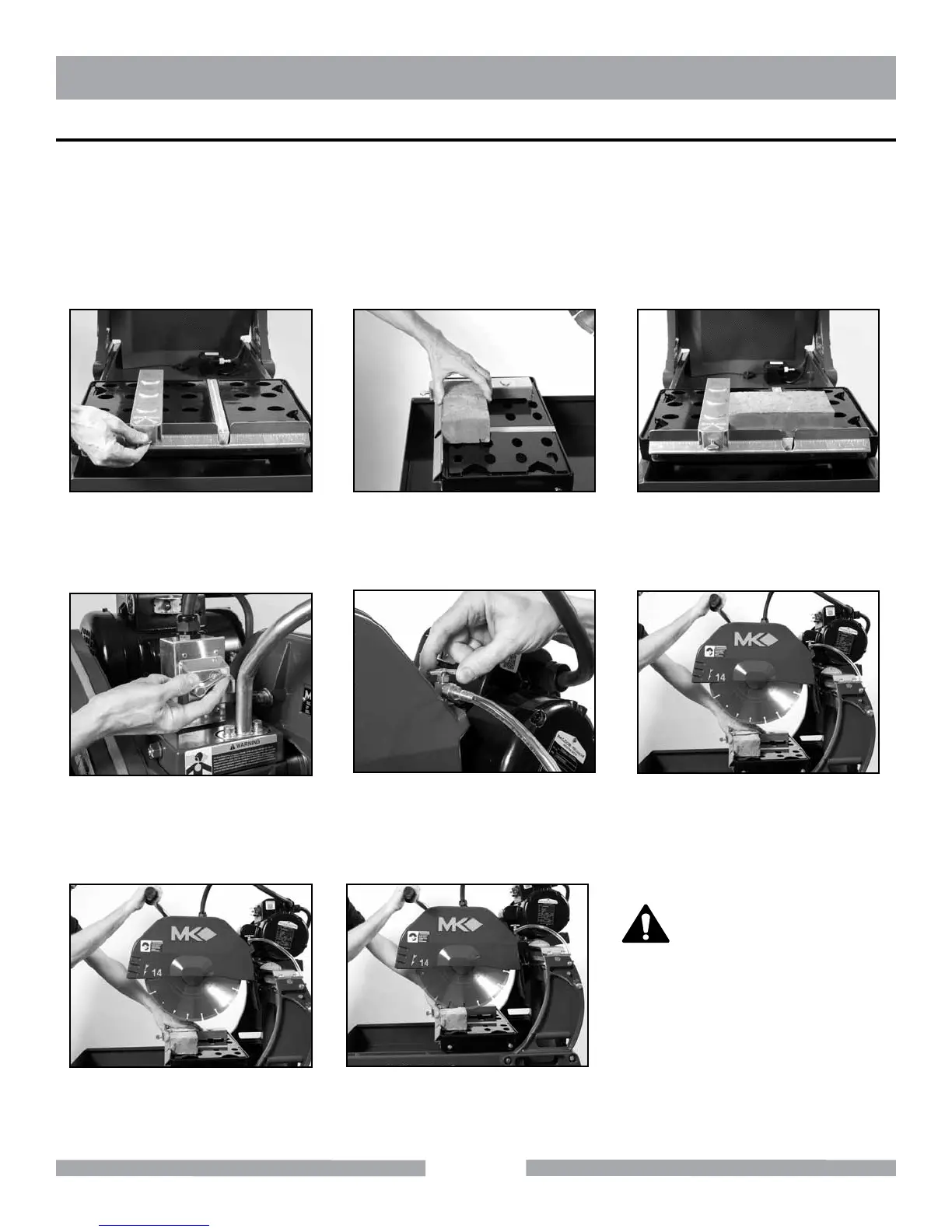

(A)

Set the adjustable Cutting Guide to

the desired length indicated on the

side of the Ruler/Stop closest to the

Wooden Strip. Tighten thumbscrew.

(B)

Place the masonry piece onto

the Movable Cutting Table.

(C)

Verify the masonry piece is seated

against the Ruler/Stop and the

adjustable Cutting Guide.

(D)

Place the ON/OFF Switch in

the ON position.

(E)

Open the Cooling Flow Control

Valve and adjust cooling ow.

Verify cooling ow exists on both

sides of the blade.

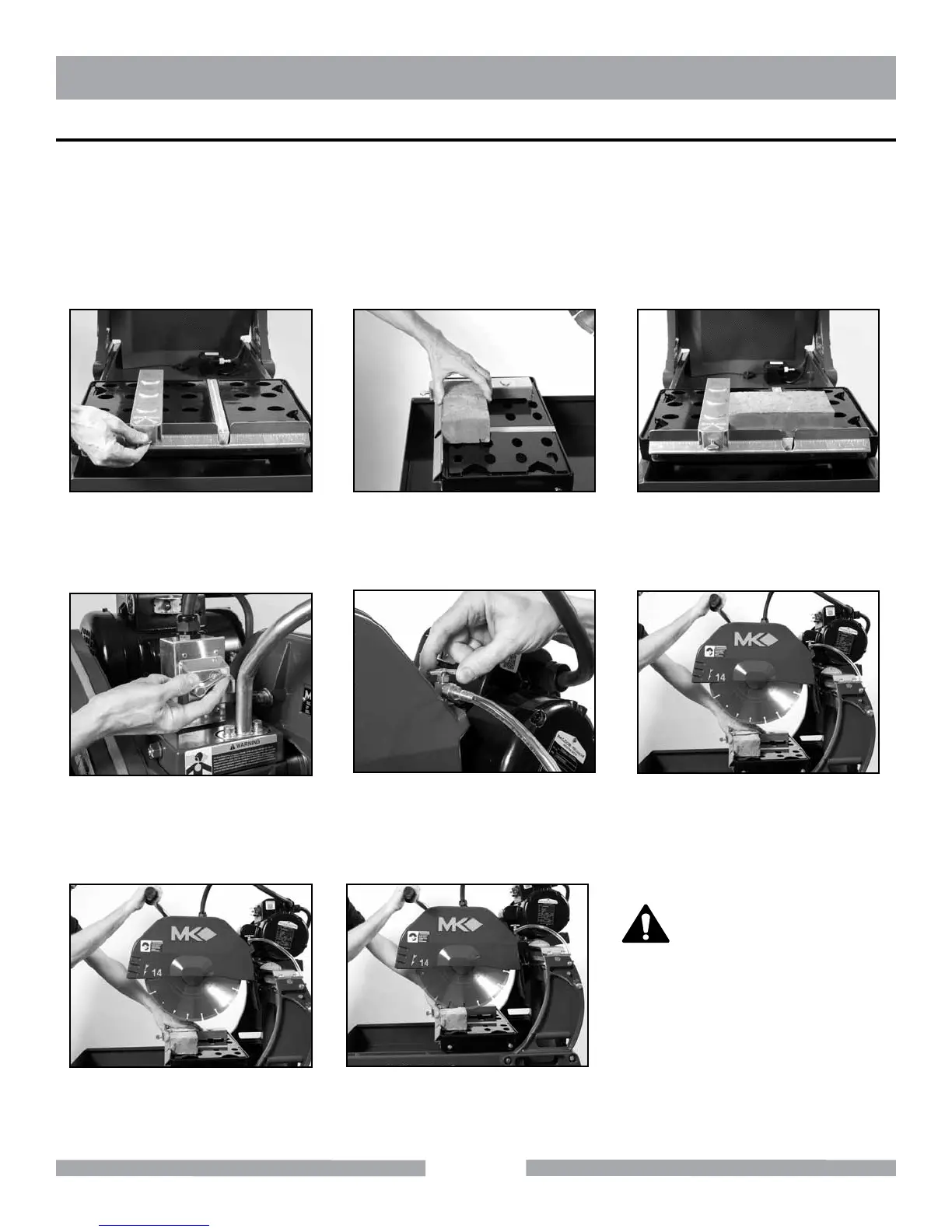

(G)

Hold the masonry piece, lower

the Cutting Head and “PUSH” the

piece toward the Blade. Lower 1/4

- 1/2 inch for "push" stroke.

(H)

Once the “PUSH” cut is complete,

lower the Cutting Head further and

“PULL” the piece back into the Blade.

CAUTION

NOTE: Skip steps E and F, if cutting dry.

• Step Cutting is the preferred cutting method for all cuts.

• When cutting hard material Step Cutting should always be used.

• Step Cutting will extend the life of the Diamond Blade.

NOTE:

Repeat F and G until cutting is

complete. Turn off saw when cut

is complete.

(F)

Position the masonry piece

below the Blade.

Loading...

Loading...