4. MAINTENANCE

To maintain the machine at maximum efficiency, have Gas Safe

Engineer or other qualified personnel perform a maintenance

check at least once a year.

Before cleaning or performing maintenance, opening or

disassembling the panels, switch off the device and turn off the gas

supply. Check the main burner and the pilot flame, the ignition

electrode, the safety valve and that there is no gas or water

leakage. Check that there is nothing obstructing the passages

within the heat exchanger or flue.

To clean the outside of the panels utilize a cloth with soap and

water. Do not use solvents, powders or abrasive sponges.

Do not clean the device and/or its parts with flammable materials

(e.g. petrol, alcohol, diesel etc.).

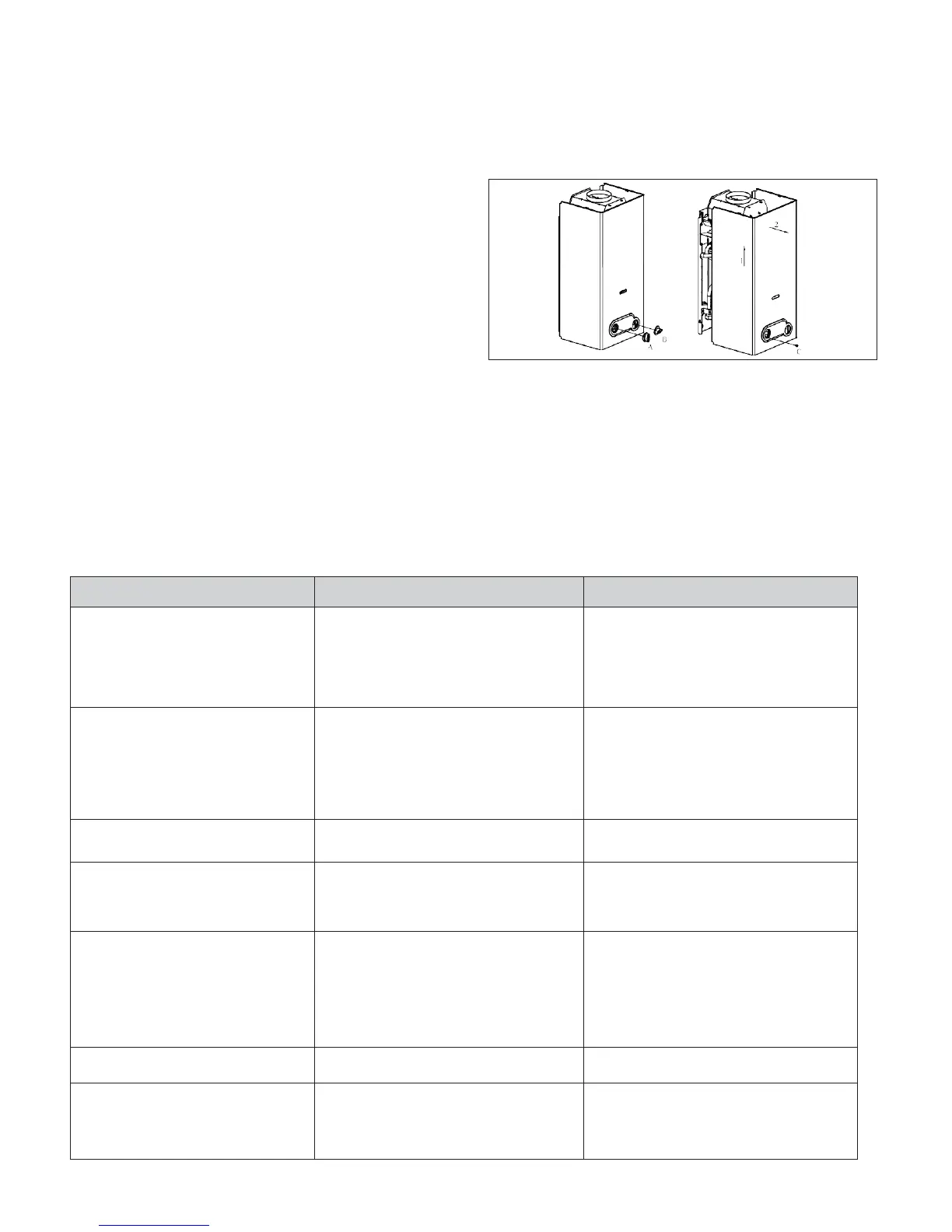

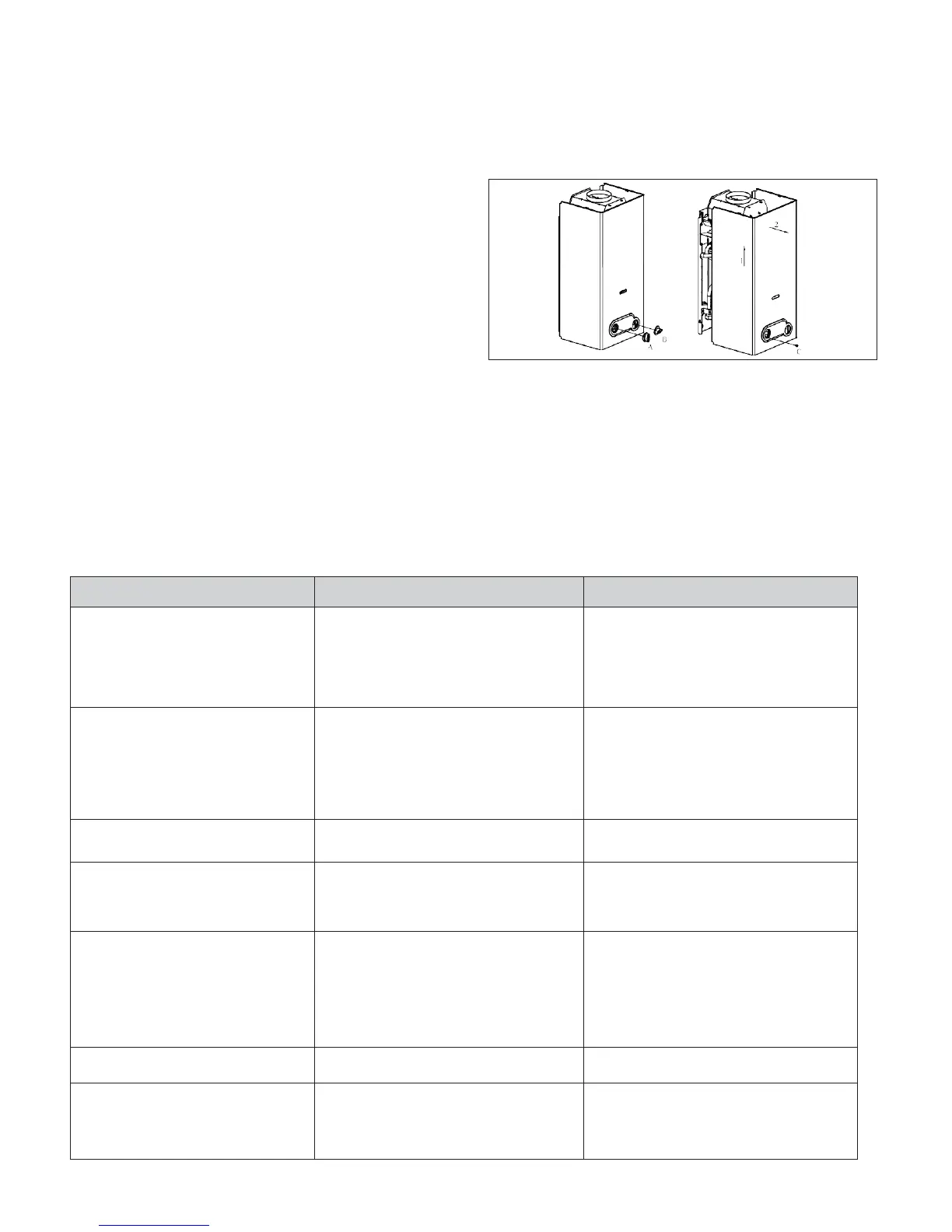

4.a Removing the casing

To remove the outer casing follow the steps below:

- Remove the selector knobs (A and B)

- Remove the screws (C)

- Shift the casing upwards to free it from the upper and lateral hooks

- Shift the casing forwards

- To reinsert the casing, follow the above steps in reverse order.

4.b Troubleshooting: problems and solutions

For the best functioning of the water heater, to prolong its lifetime

and ensure that it is always safe, it should be inspected at least once

a year by a gas safe engineer. The gas safe engineer is to perform

the following maintenance operations:

- Remove any rust from the burner

- Remove any deposit from the electrodes

- Clean the combustion chamber

- Check the ignition, switching off and general functionality of the

appliance

- Check that the gas and water pipes and connections are sealed

Warning: the following repair instructions are only to be performed

by Gas Safe Engineers or other qualified personnel.

PROBLEM CAUSE SOLUTIONS

There is no spark - appliance spark wire is disconnected - reconnect

- piezoelectric mechanism broken

- adjust

- no gas supply - open the appliance gas isolation valve

- air in the gas tubes - purge air by turning on all gas rings on hob

for 30 seconds

The pilot does not stay on - thermocouple faulty - replace

- broken magnetic valve - replace

Pilot on but the main burner does not

ignite

- insufficient water pressure

- the diaphragm is broken - replace

The burner does not switch off when

the water turns off

- contamination on the gas valve seat - test, clean

- gas valve push rod is locked in the open

position

- Check the correct operation of the cold

water push rod , dis-assemble, clean or

Delayed burner activation - pilot burner flame is too far from main

burner flame or it is too short

- check inlet gas pressure, clean injector and

pilot burner

The heat exchanger fins becomes

sooty in a small amount of time

- poor draught, adverse weather conditions

Loading...

Loading...