2.1.5. Testings

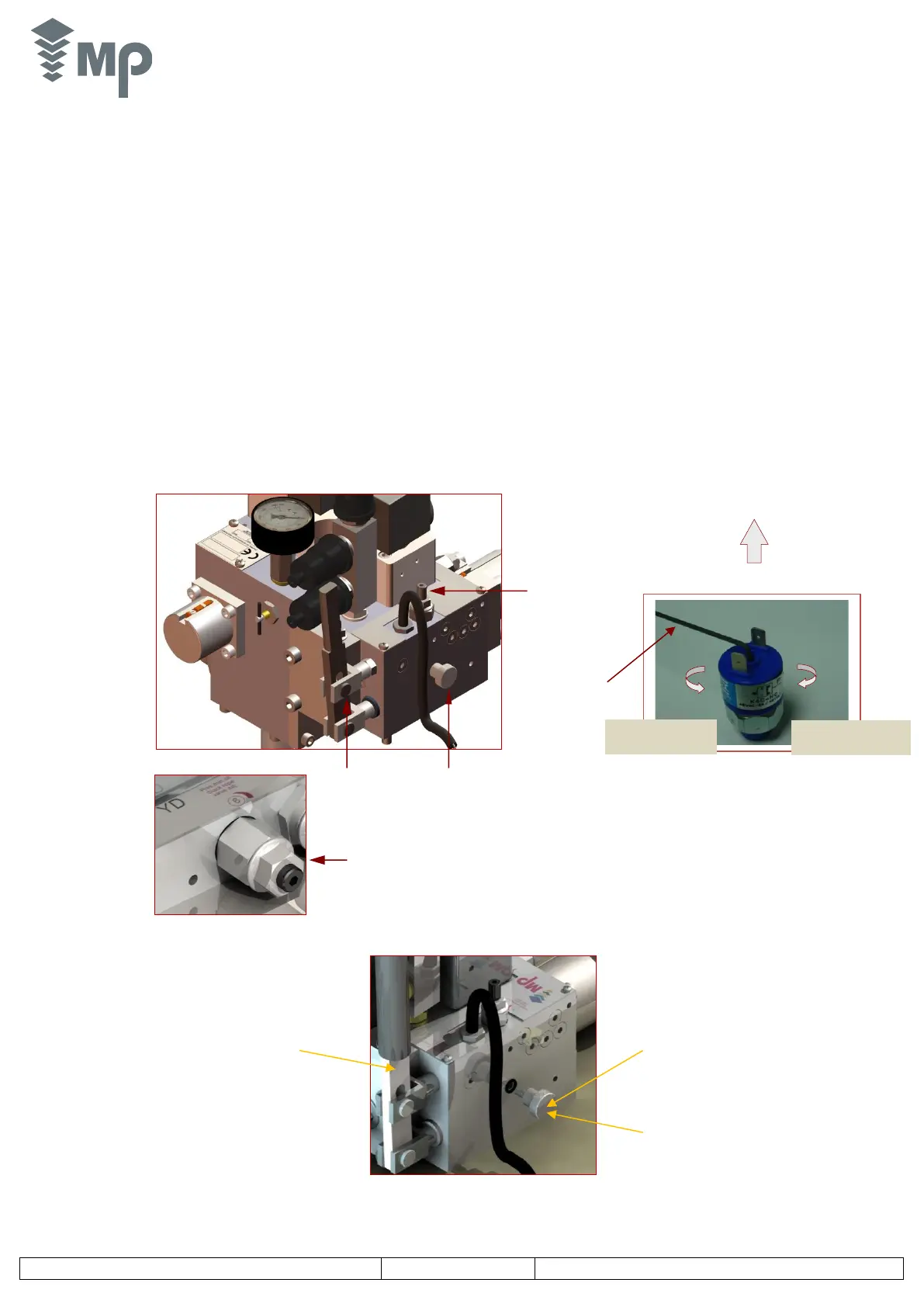

1. Pressure relief valve. Screw 1

1. Load the lift car with 100% of the rated load.

2. Open the manometer protection key and take the pressure reading (full load pressure).

3. Close the shut-off valve and disconnect the maximum pressure reading switch from the circuit if any.

4. Send the lift up and make a note of the manometer reading once it is stabilized (tripping pressure).

5. This pressure should be 1,4 times the full load pressure.

6. If the pressure is not correct, tighten screw 1 to increase the tripping pressure (+ pressure) or loosen to reduce it (- pressure).

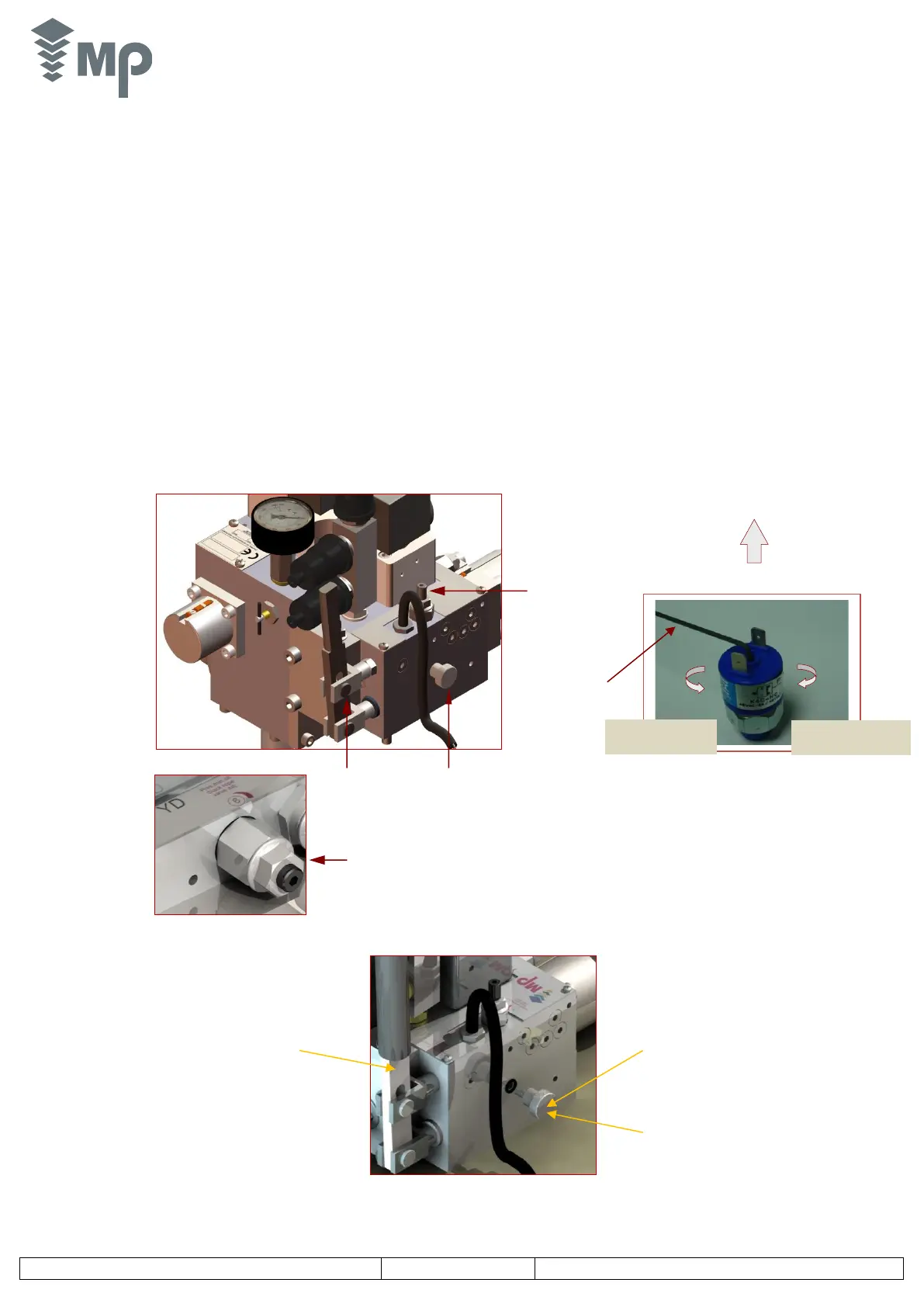

2. Maximum or minimum pressure switch (optional)

1. Close the shut-off valve and send the lift up.

2. Note the cut-off pressure; it should be between 1,1 and 1,2 times the full load pressure.

3. If it is not correct, adjust the pressure switch using an appropriate screwdriver; see figure below.

3. Hand pump. Screw 7

1. Pump the lever and check the lift goes up.

2. If not, the hand pump needs priming. To do this, pump the lever while loosening and tightening the bleeding screw several times, until an opposition in

movement is observed. Then tighten the screw.

3. To check the tripping pressure of the relief valve:

- Close the shut-off valve and cut off the power.

- Pump the lever and note the manometer reading after it is stabilized.

- Pressure should be 2,3 times the full load pressure.

- Should it not be correct, tighten the relief valve screw to increase the tripping pressure, or loosen to reduce it.

Bleeding Hand Pump

Loading...

Loading...