I 15 I

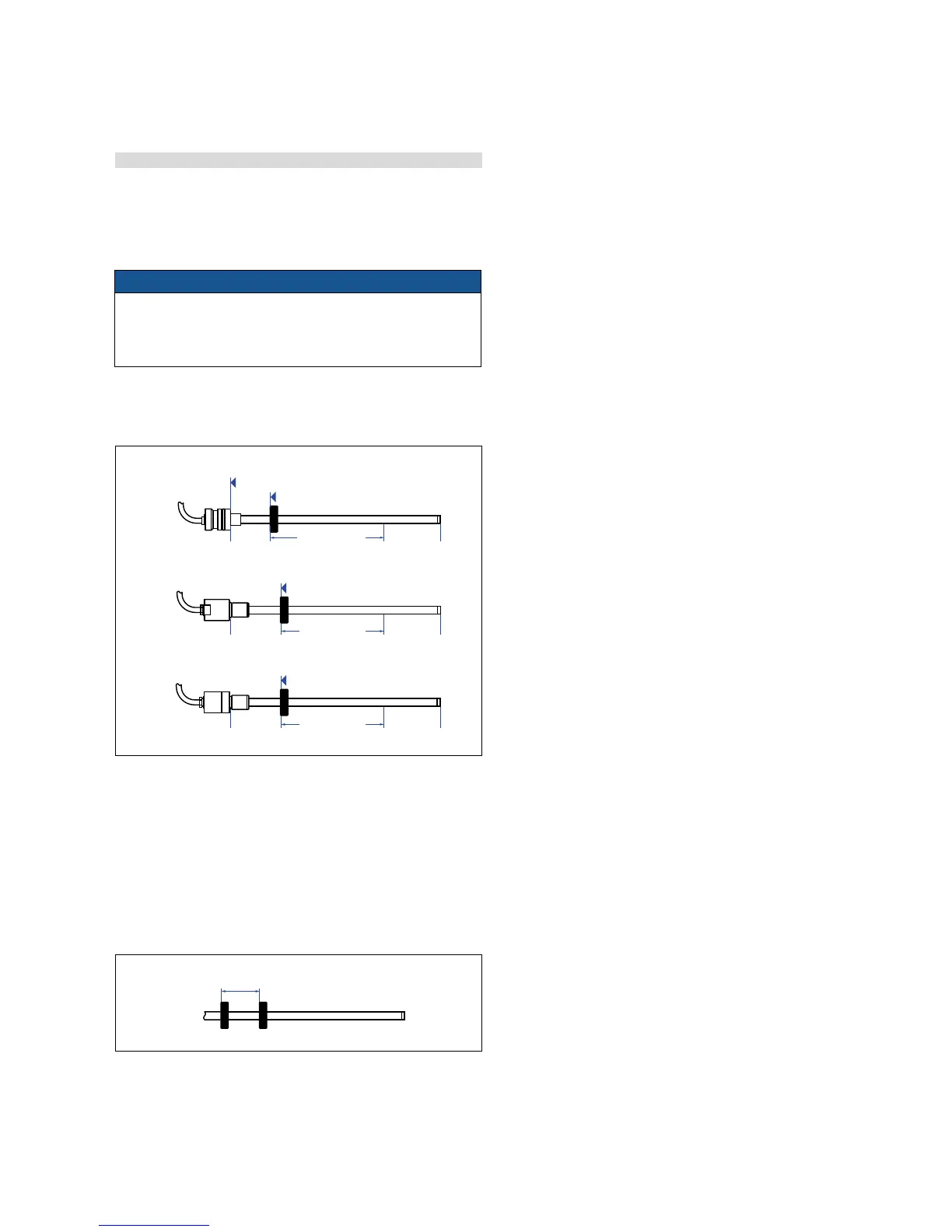

4.4.1 Mounting distances

Active measuring range

The technical data of each sensor is checked as well as documented

and the active stroke length (useful electrical stroke) with its start

and end position is adjusted during final inspection and testing

(see Fig. 22).

NOTICE

On all sensors, the areas left and right of the active stroke length

are provided for mounting and damping of the measuring signal.

They should not be used for measurement, but the active stroke

length can be exceeded without problem.

Mechanical zero

To ensure that the entire measuring range can be used electrically,

the position magnet must be mounted mechanically as follows:

63.5 / 66

(2.5 / 2.6)

51

(2)

Start position

Start position

Start position

RD4 type »S«

RD4 type »M«

RD4 type »C«

Reference edge of mounting

Stroke length

Stroke length

Stroke length

63.5

(2.5)

21.4

(0.84)

51

(2)

63.5 / 66

(2.5 / 2.6)

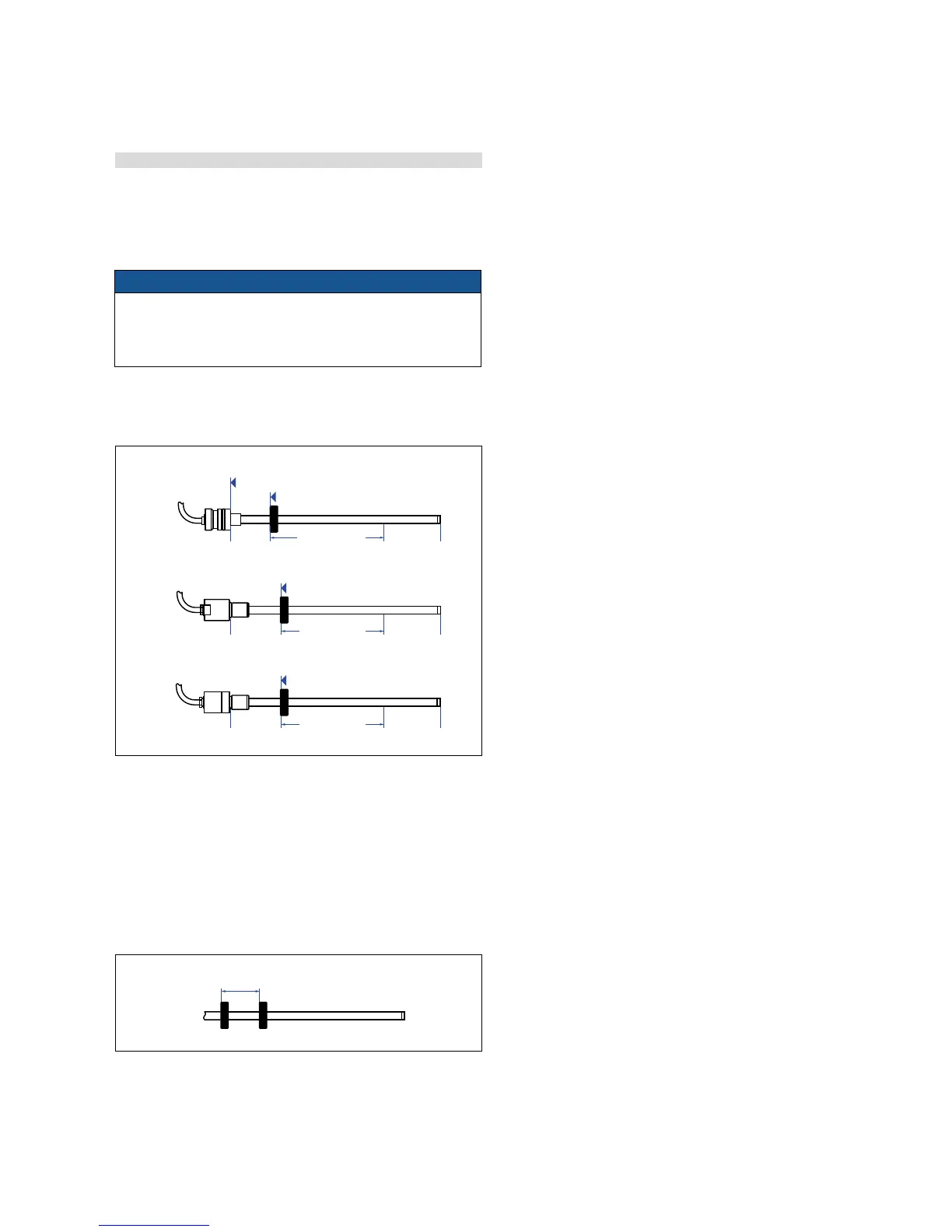

minimum 75 (3)

Mounting ring manget

Mount the magnetic with the non-magnetic material for mounting,

screws, spacers, etc..

– Max. permissible surface pressure: 40 N/mm

2

– Max. fastening torque for M4 screws: 1 Nm; use washers, if necessary

Multi-position measurement

The minimum distance between the magnets is 75 mm (3 in.)

Fig. 22: Mechanical zero

Fig. 23: Minimum distance for multi position measurement

Controlling design dimensions are always in metric units and measurements in ( ) are in inches

Loading...

Loading...