(1.06)

22.9

(0.9)

12.7

(0.5)

4.4

(0.17)

10

(0.39)

5.8

(0.23)

Ø 22.9

(Ø 0.9)

45°

4.4.2 Installation of RD4 with pressure t ange »S«

Cylinder mounting

For installation in fluid power cylinders, the standard sensor system

consists of the rod and the mounting flange, and the B type electron-

ics. Install the rod using the fit and seal it off by means of the O-ring

and the supporting ring. Block the rod using a shoulder screw. The

adaptor plate of the separate electronics housing facilitates mounting

on the outside of small cylinders. Advantage of this version: Connec-

tion to the measuring rod is via the bottom of the housing. Thus the

sensor system is fully encapsulated and protected against external dis-

turbances.

Note for cylinder installation:

– The position magnet should not grind on the measuring rod.

– The bore in the piston rod is dependent on the hydraulic pressure

and the piston’s velocity. The minimum drilling should be 13 mm

(0.52 in.).

– Do not exceed the peak pressure.

– Protect the measuring rod against wear.

NOTICE

To fulfill the EMC standards for emission and immunity the

following points are necessary:

• The sensor electronics housing has to be connected to machine

ground.

• The cable between the sensor and the electronics must be

integrated into a metallic housing.

O-ring 21.9 × 2.6 (no. 560 705)

Back-up ring (no. 560 629)

Position magnet

Non-magnetic

material

32

(1.26)

5

(0.2)

20.32

(0.8)

20

(0.79)

Bore

27 H7

(1.07)

75°

(3)

2.54

(0.1)

Ø 10…20 (Ø 0.39...0.79)

bore for cable to electronic housing

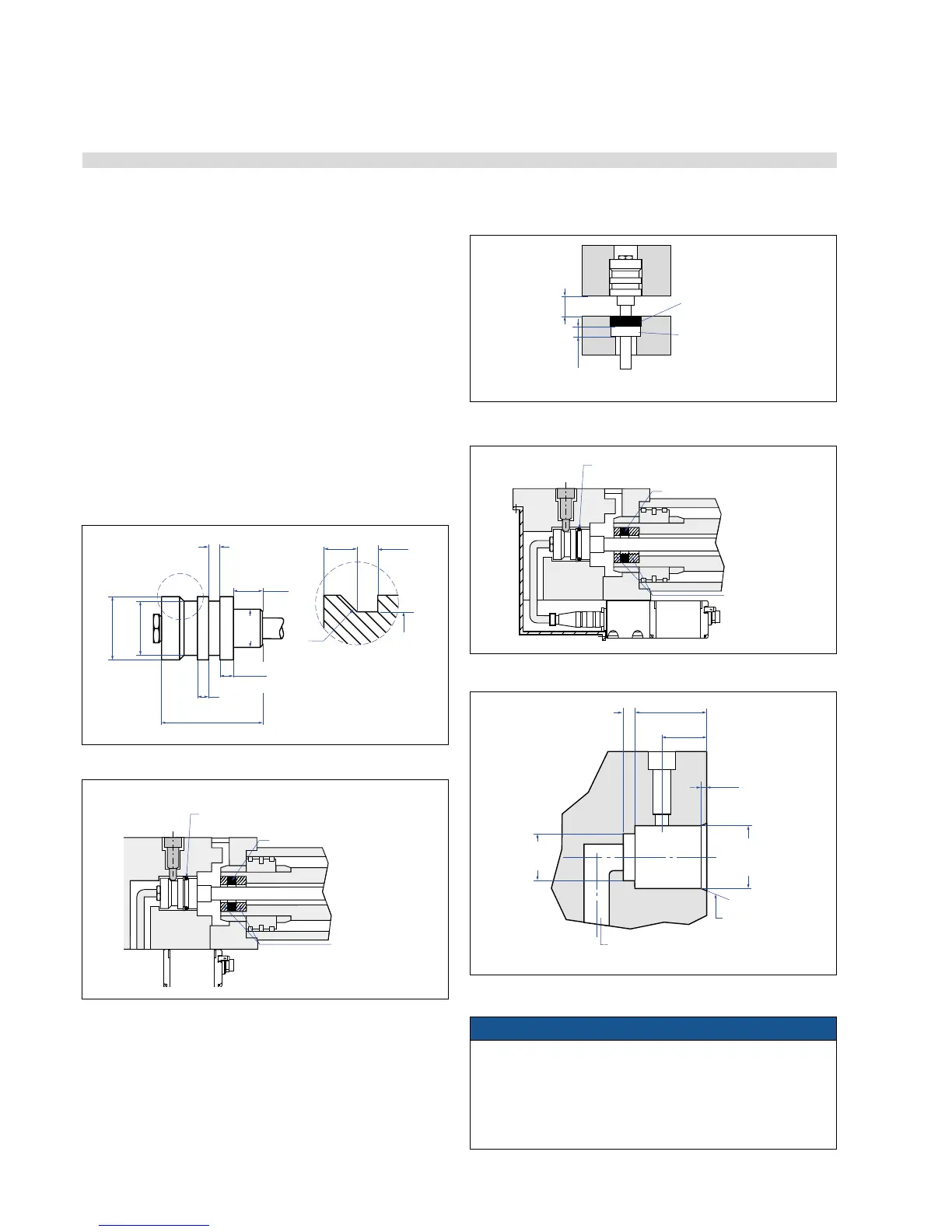

Fig. 24: Pressure fit flange details

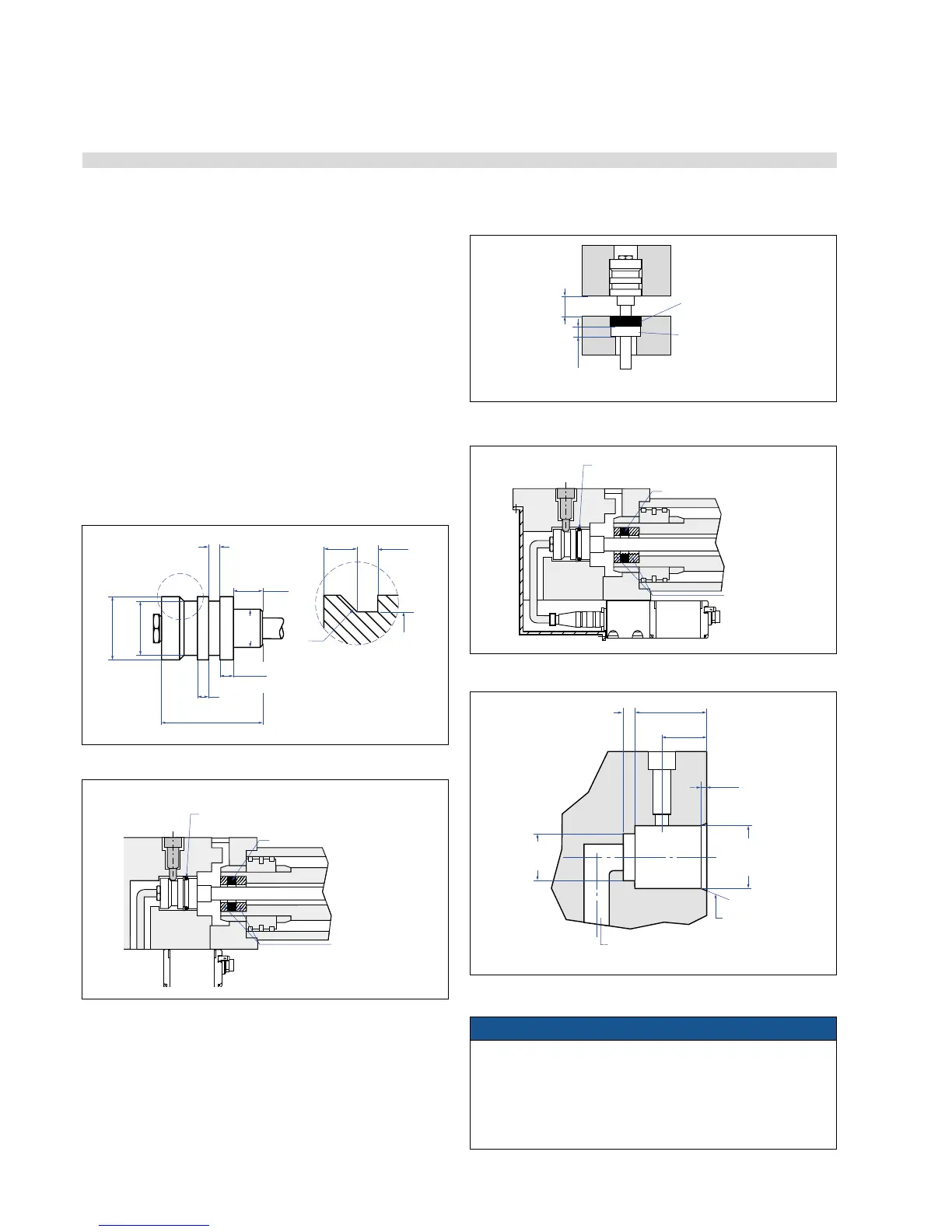

Fig. 25: Mounting example Pressure fit flange »S« and sensor electronics with bottom

cable entry

Fig. 26: Minimum installation dimensions for magnetic material

Fig. 27: Mounting example Pressure fit flange »S« and sensor electronics with side cable

Fig. 28: Mounting detail: Setscrew 8 M6 - ISO 7379 with internal hexagon

Controlling design dimensions are always in metric units and measurements in ( ) are in inches

Loading...

Loading...