I 17 I

4.4.3 Installation of RD4 with threaded ange »M« & »T«

Rod

The sensor’s pipe will be fixed via the threaded flange M18×1.5 or

3/4”-16 UNF.

Mounting should be with non-magnetic material. If using magnetic

material necessarily follow the displayed installation dimensions.

Cylinder mounting

– The position magnet should not grind over the measuring rod.

– The bore in the piston rod is dependent on the hydraulic pressure

and the piston’s velocity. The minimum drilling should be 12 mm

(0.5 in.).

– Do not exceed the peak pressure.

– Protect the measuring rod against wear

– Pressure sealing is defined by cylinder manufacturer

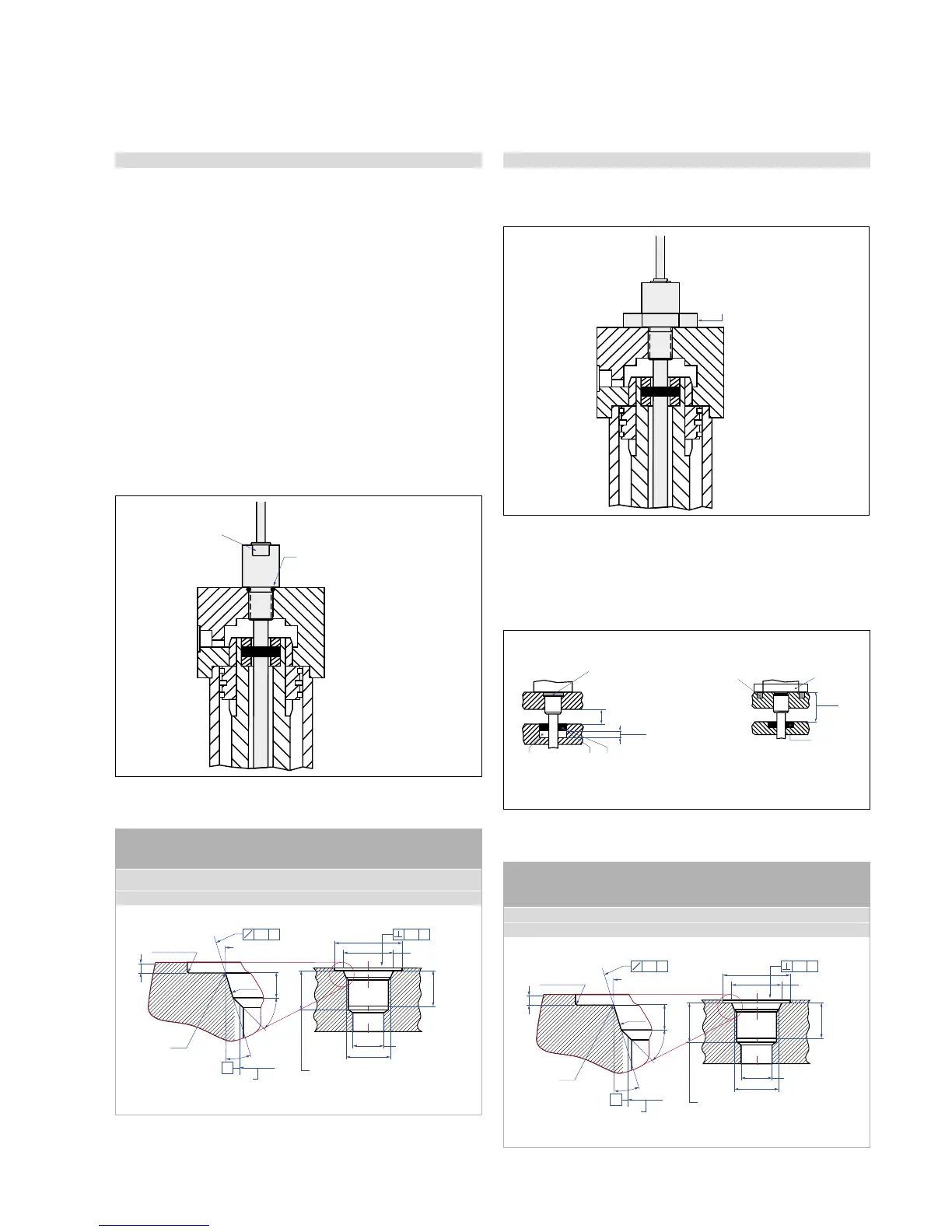

Mounting example threaded ange »M«

Sealing results from the provided O-ring mounted in the undercut.

AF23

Screw thread

< 50 Nm

O-ring

Alternative screwing bore

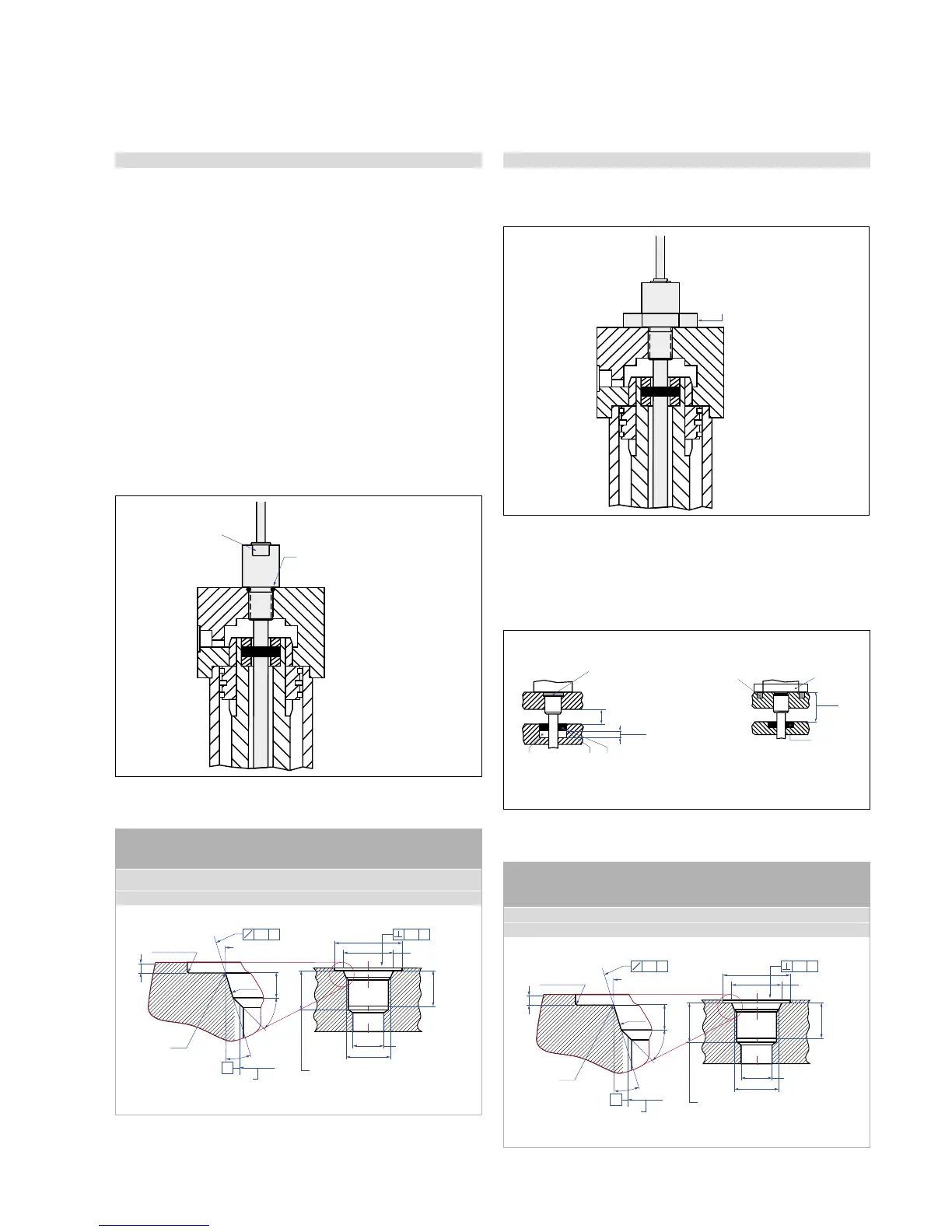

4.4.4 Installation of RD4 with threaded ange »C« & »D«

The sensor’s pipe will be fixed via the threaded flange M18×1.5 or

3/4”-16 UNF.

AF46

Screw thread

< 50 Nm

Position magnet

For accurate position measurement mount the magnet with

non-magnetic fastening material (screws, supports etc.).

Fig. 29: Mounting example for threaded flange

Fig. 30: Alternative screwing bore: Threaded flange M18×1.5 based on DIN ISO 6149-1

Fig. 31: Mounting example for threaded flange »C«

Fig. 32: Installation with non-magnetic & magnetic material

Fig. 33: Alternative screwing bore: Threaded flange M18×1.5 based on DIN ISO 6149-1

Controlling design dimensions are always in metric units and measurements in ( ) are in

inches

Thread

(d

1

×P)

d

2

d

3

d

4

d

5

L

1

L

2

L

3

L

4

Z°

M18×1.5 55 mm 13 mm 24.5 mm 19.8 mm 2.4 mm 28.5 mm 2 mm 26 mm 15°

3/4x16 See Appendix B

This dimension applies

when tap drill cannot

pass through entire boss

Thread (d

1

×P)

(Reference size)

Applies at Ød

4

A

R 0.4 max.

Loading...

Loading...