Temposonics

®

R-Series EtherNet/IP

TM

Operation Manual

I 18 I

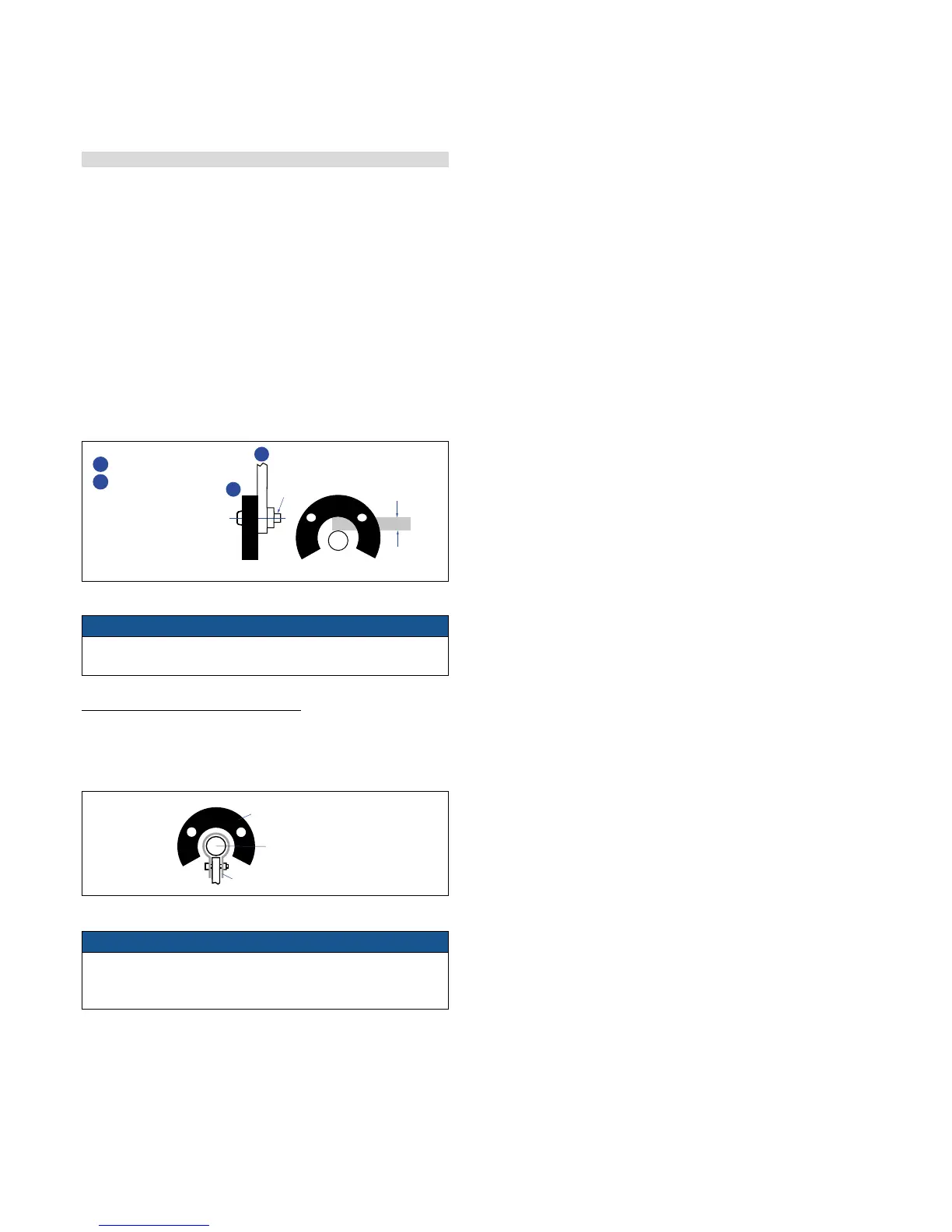

Fig. 34: Mounting device for U-magnet

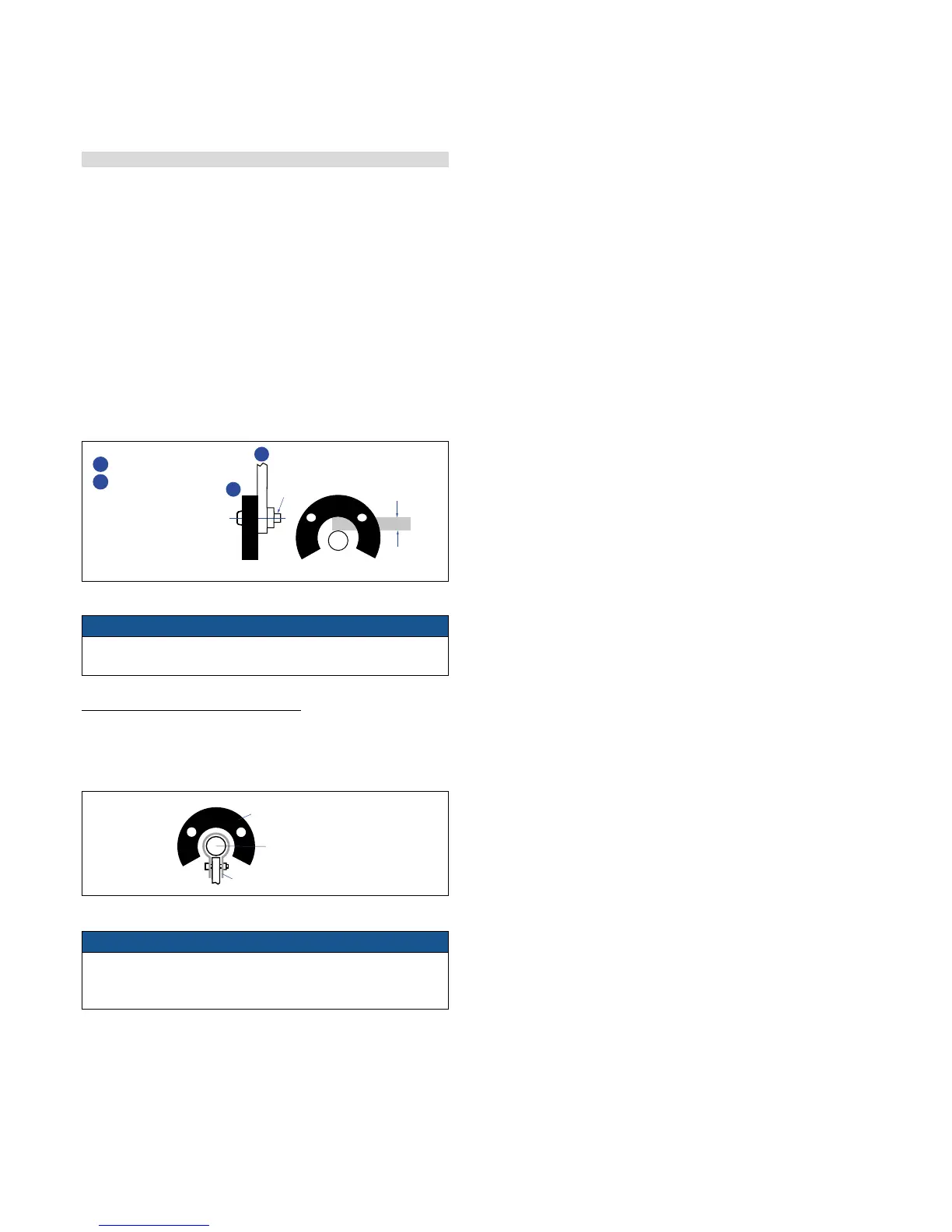

Large stroke lengths from 1 meter (39 in.)

Horizontally installed sensors should be supported mechanically at the

rod end. Longer rods require evenly distributed mechanical support over

the entire length. In this case an U-magnet (see fig. 35) is used for

NOTICE

A maximum permissible air gap of 3 ±1 mm (0.12 in.) must not be

exceeded.

NOTICE

Use the electronics and sensor rod with the same serial number

together! For further information contact the application

engineering team.

Fig. 35: Example of sensor support

SW 46

Anziehmoment

≤ 50 Nm

> 30

Magnet

Empfohlene

Hydraulik-

abdichtung

Abb. 10

Einbau mit unmagnetischem Material

Magnet

nicht-magnetisbare

Distanzscheibe

> 15

min. 5

Abb. 11

Einbau mit magnetisierbarem Material

Abb. 12

Beispiel Sensorunterstützung

Alternative

Hydraulikdichtung

O-Ring 15,3 x 2,2

Sensor-Druckgehäuse

Stab mir Flansch

bleibt im Zylinder

Ringmagnet

Basissensor

Elektronikkopf mit Messeelement

austauschbar über zwei M4 Schrauben

mit 2,5 mm Innensechkant,

Anziehmoment max. 1,3 Nm

U-magnet

Sensor rod

Non-magnetic retaining clip

4.4.4 Magnet installation

Mounting the ring magnet

Install the magnet using non-magnetizable material for mounting

device, screws, spacers etc.

– Max. permissible surface pressure: 40 N/mm

2

– Max. fastening torque for M4 screws: 1 Nm; use washers,

if necessary

Mounting the U-magnet

Using a non-magnetizable mounting device is mandatory. The magnet

must not rub against the measuring rod. Alignment errors are

compensated via the air gap.

– Max. surface pressure: 40 N/mm

2

– Max. fastening torque for M4 screws: 1 Nm;

use washer, if necessary

Controlling design dimensions are always in metric units and measurements in ( ) are in inches

3 ±1

(0.12 ± 0.04)

M4

2

1

U-magnet

2

Non-magnetic

mounting device

Loading...

Loading...