• When the tractor is moving, the display (7) shows the tractor speed indication (6)

(km/h), while the indication (5) disappears. The electric signal of the speed comes from

the speed sensors mounted on the rear axle cover (BV1, BV2). The speed readings are

taken through a signal from the sensor mounted on the pinion of the final drive of the

wheel rotating at lesser speed. The calculated speed is higher than the actual one, be-

cause no tractor skid is the taken into account;

• On starting the engine, the pointer indicator (8) moves round the index dial (1) to display

the rotational speed of the engine crankshaft. At the same time, the display (4) shows the

PTO indication (rpm). The scale (3) is assigned to the PTO I and the scale (2) – to the

PTO II. The electric signal of the rotational speed is taken from the phase winding of the

alternator.

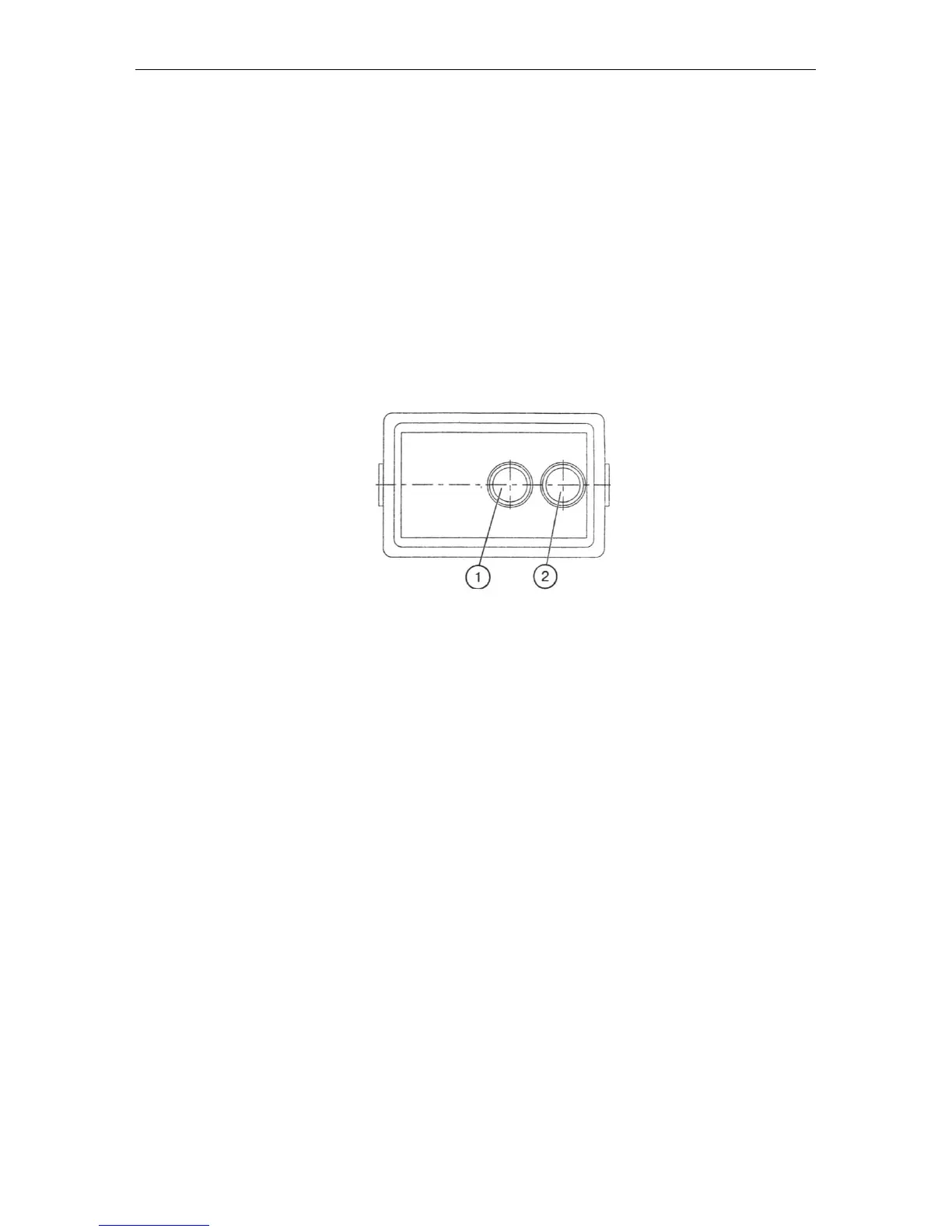

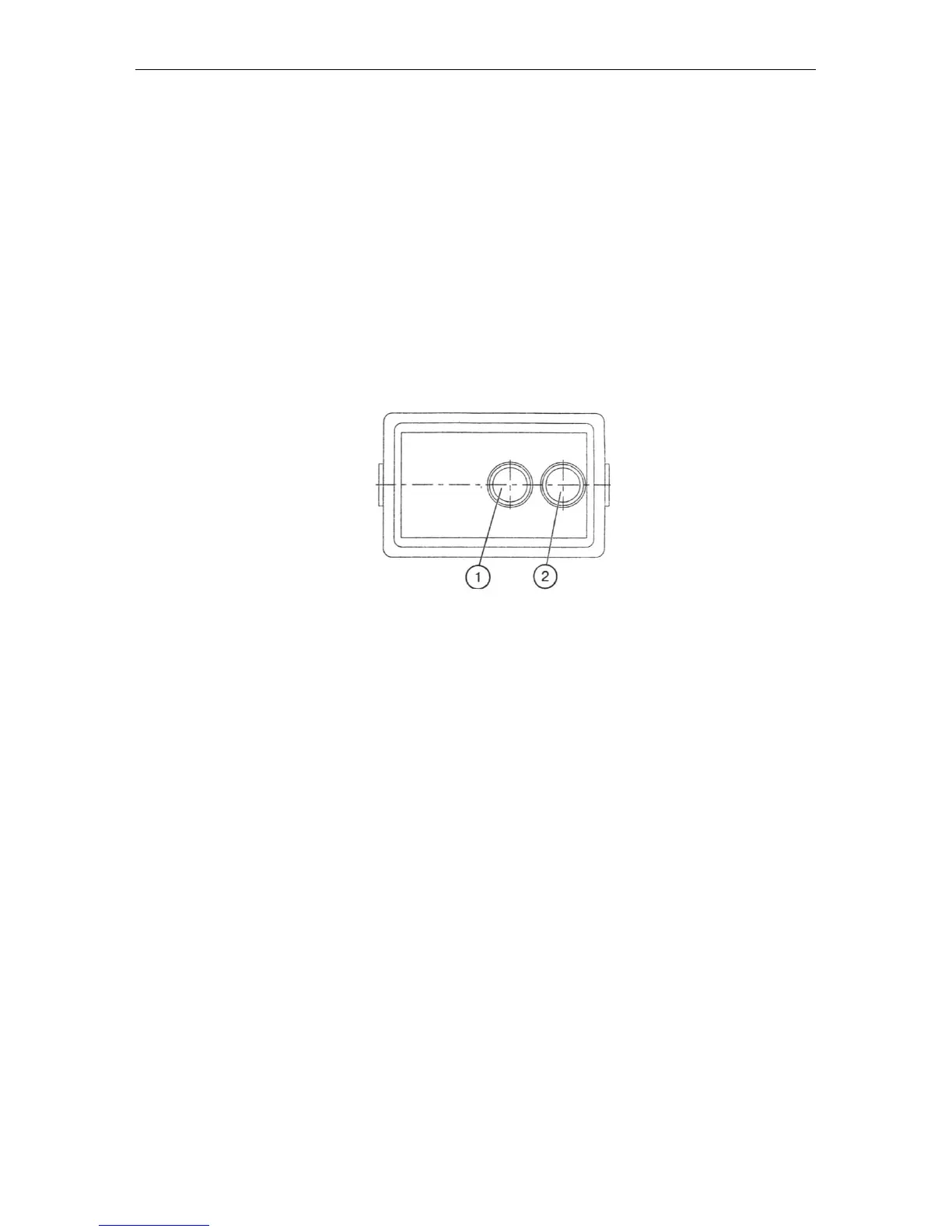

1.2. Tachospeedometer control board (Fig. 2)

The control board is installed in the dashboard and serves for programming the

tachospeedometer to the specific model of the MTZ tractor.

Fig. 2. Control board (А3):

1 – Button for setting the tachospeedometer to the programming mode and selecting the

programming parameter on the tachospeedometer display (7). 2 – Button for selecting

the value of the coded parameter shown on the display (7)

1.3. Programming the tachospeedometer АР70.3813

ATTENTION! The tachospeedometer has been programmed just to your tractor make at

the factory. Re-programming is required in case of tyre type changing. Do not re-program

the tachospeedometer, if unnecessary.

The tachospeedometer shall be programmed to ensure the correct display of the follow-

ing tractor’s parameters: engine rotational speed, tractor motion speed and PTO rota-

tional speed (540 and 1000 rpm).

Programming procedure:

– Remove the control board cover;

– Press the button (1) to enter the programming mode (Fig. 2).

1. To ensure the correct display of the tractor motion speed, it is necessary to program

the tachospeedometer to the number of teeth of the pinion at the place of installation of

the speed sensors (parameter “Z”) and rear wheel rolling radius (parameter “R”). To do

this:

– press the button (1) of the board and call the parameters “Z” and “R” in turn to the dis-

play (3) of the tachospeedometer (4);

– press the button (2) of the board and set the number of teeth (Z) according to Table 1

and value Rk according to Table 2:

Loading...

Loading...