39

Bearings Cont.

Grease Zerk Locations

As outlined under Axle Configurations and Grease Zerk Configurations, there are (2) possible setups for XL. Be-

low is a description and reference to accompanying diagram for reference under Greasing Axle Bearings.

1. Standard zerks: Figure-9.

2. Optional relocated zerks: Figure-10.

Greasing Bearings - Standard

1. See Accessing the Mudd-Ox to remove all floor boards, lower seats and engine cover.

2. See Wheel Removal under Tires/Wheels to gain access to the outer axle bearings.

2. Locate each bearing as shown in Figure-9.

3. For each bearing, there is a grease zerk on the bearing flange itself. Connect the grease gun onto the fitting as

shown in Figure-5. Slowly pump grease into the bearing flange. Once it begins to seep out of the flange/block,

immediately stop. Note: It can seep out of either side of the bearing. If the grease is only seeping around the

grease gun tip, the tip is not fully connected to the grease fitting.

4. See Wheel Installation under Tires/Wheels.

5. See Accessing the Mudd-Ox to reinstall floor boards, seats and engine cover if removed.

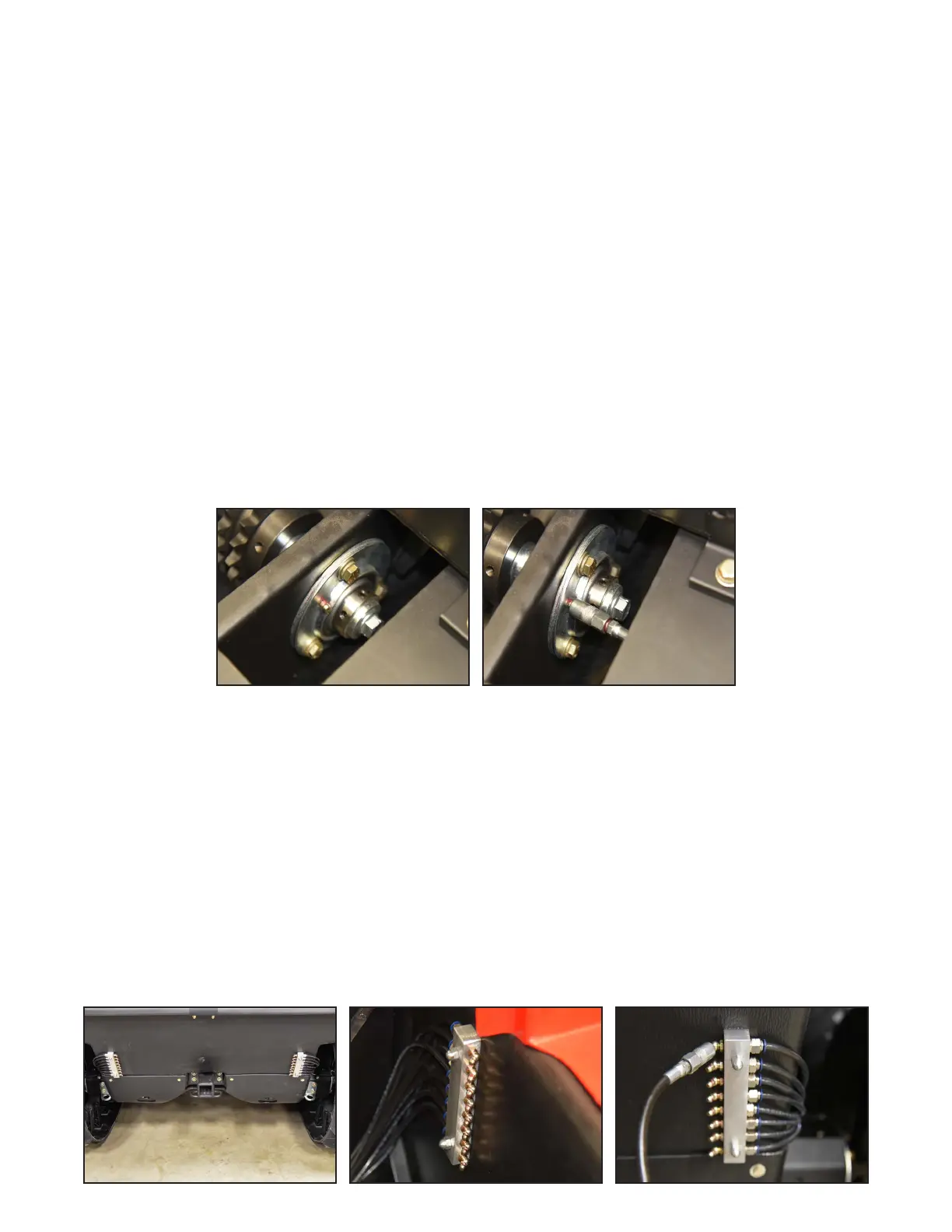

Figure-4 Figure-5

Greasing Bearings - Zerk Relocated

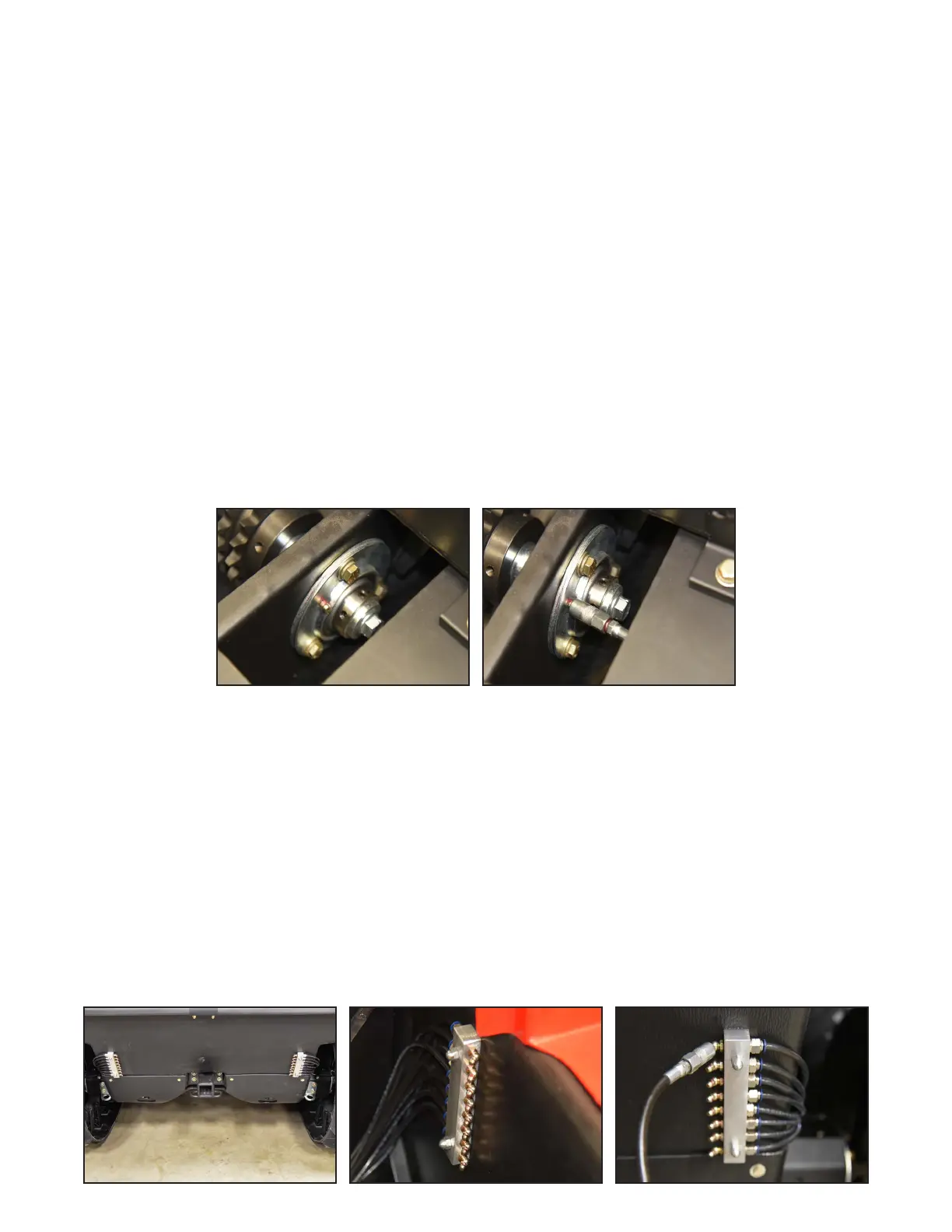

1. See Engine Cover Removal under Accessing the Mudd-Ox. Locate the (3) grease zerk relocation blocks. There

are (2) on the outside rear of the Mudd-Ox (Figure-6) and (1) on the right side engine compartment (Figure-7).

2. On each grease block is a row of grease zerks. Connect the grease gun onto the top fitting as shown in Figure-8.

Slowly pump grease into the fitting. Pump approximately 3-5 times.

3. After greasing the top zerk, proceed to the next one down and repeat step #2. Do this until all zerks on all (3)

blocks have been adequately greased.

Figure-6

Outer Blocks

Figure-7

Inner Block

Figure-8

Grease Gun Connected

Standard Zerk Grease Gun Connected

Loading...

Loading...