38

Bearings

Throughout the Mudd-Ox are bearings which enables parts to rotate. It’s extremely important to maintain bear-

ings, as replacement is a time consuming and expensive process. Grease bearings every 25 hours or after enter-

ing mud or water, whichever comes first. Only use marine wheel bearing grease.

Signs of Worn Bearings

• Water leaks inside the Mudd-Ox around the outer axle bearings.

• Control and shift lever assemblies wobble in all directions.

• The axle and wheel assembly wobbles in all directions.

• Drivetrain is put into a bind, making a “popping” sound.

• Sprockets and chains have uneven wear.

Inspection

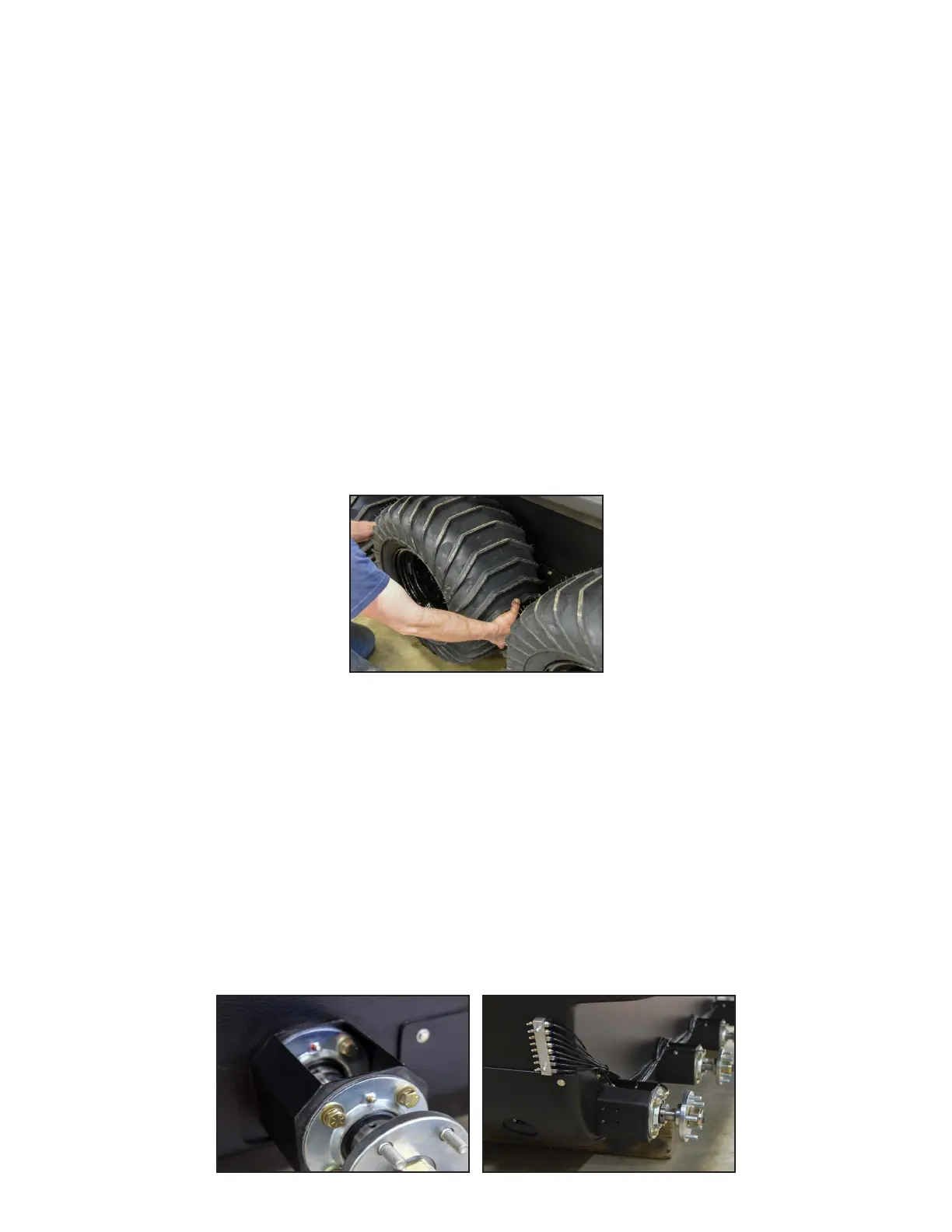

See Raising the Mudd-Ox under Jack Points to raise the vehicle using the wooden block method. To check axle

bearings, simply grab a wheel and firmly attempt to wobble it in all directions. If the entire axle assembly has any

slop or movement, at least (1) axle bearing is worn. As it is difficult to determine exactly which bearing is faulty,

we recommend replacing all bearings on the axle assembly while it’s being serviced. See Removal under Axles

replacement.

Figure-1

Check for Slop

Bearing Quantities

For each axle, there is (1) inner bearing and (2) outer bearings. Total (24) axle bearings, with (8) being inside the

Mudd-Ox lower body and (16) being outside.

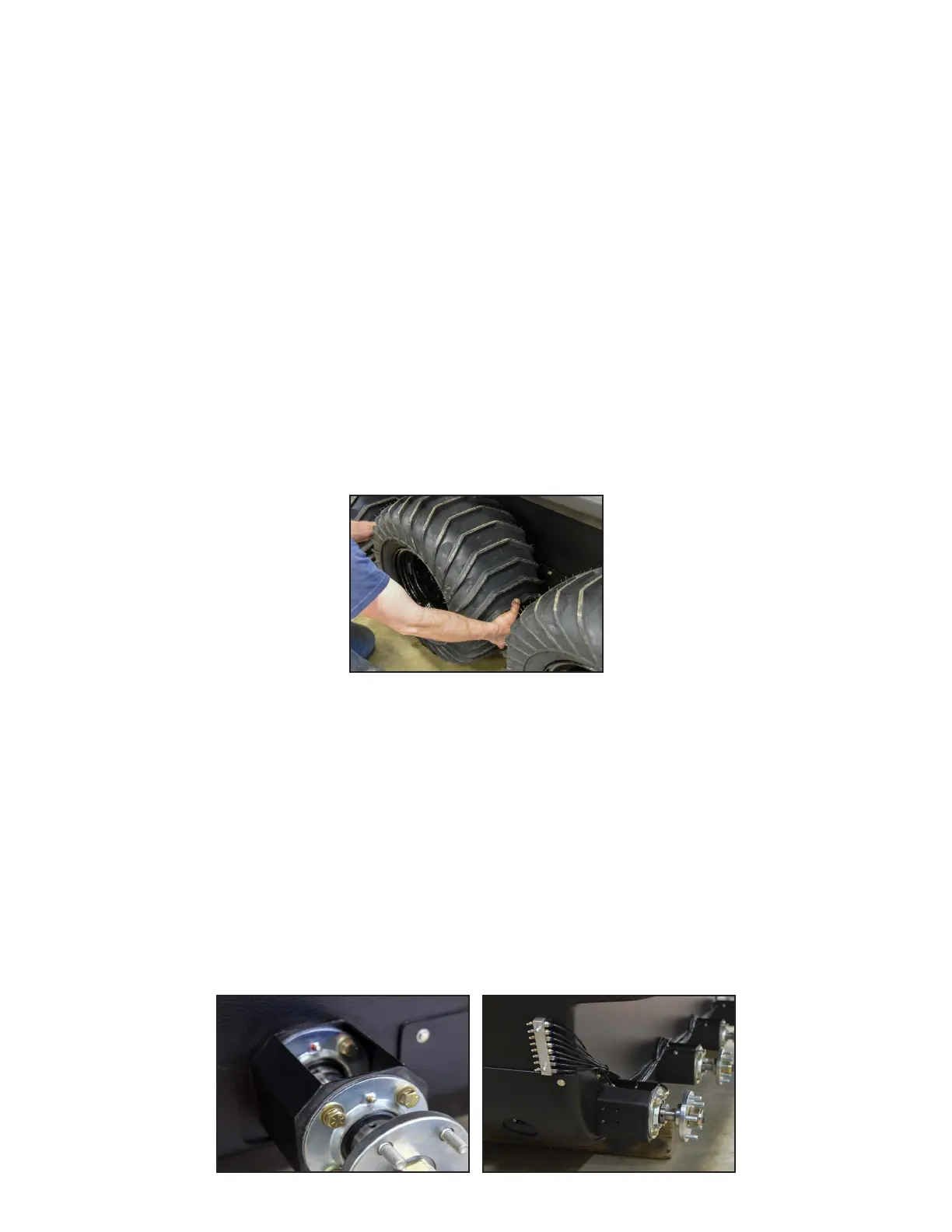

Grease Zerk Configurations

XL may have various grease zerk setups:

A. Standard zerks: The grease zerk for each bearing is located right on its flange. You must reach each individual

bearing to perform maintenance (Figure-2).

B. With optional Grease Zerk Relocation Convenience Kit: All axle bearing grease zerks are rerouted to centralized

locations. This makes greasing much faster and easier (Figure-3).

Figure-2

Standard Zerk

Figure-3

Optional Relocated Zerk

Loading...

Loading...