42

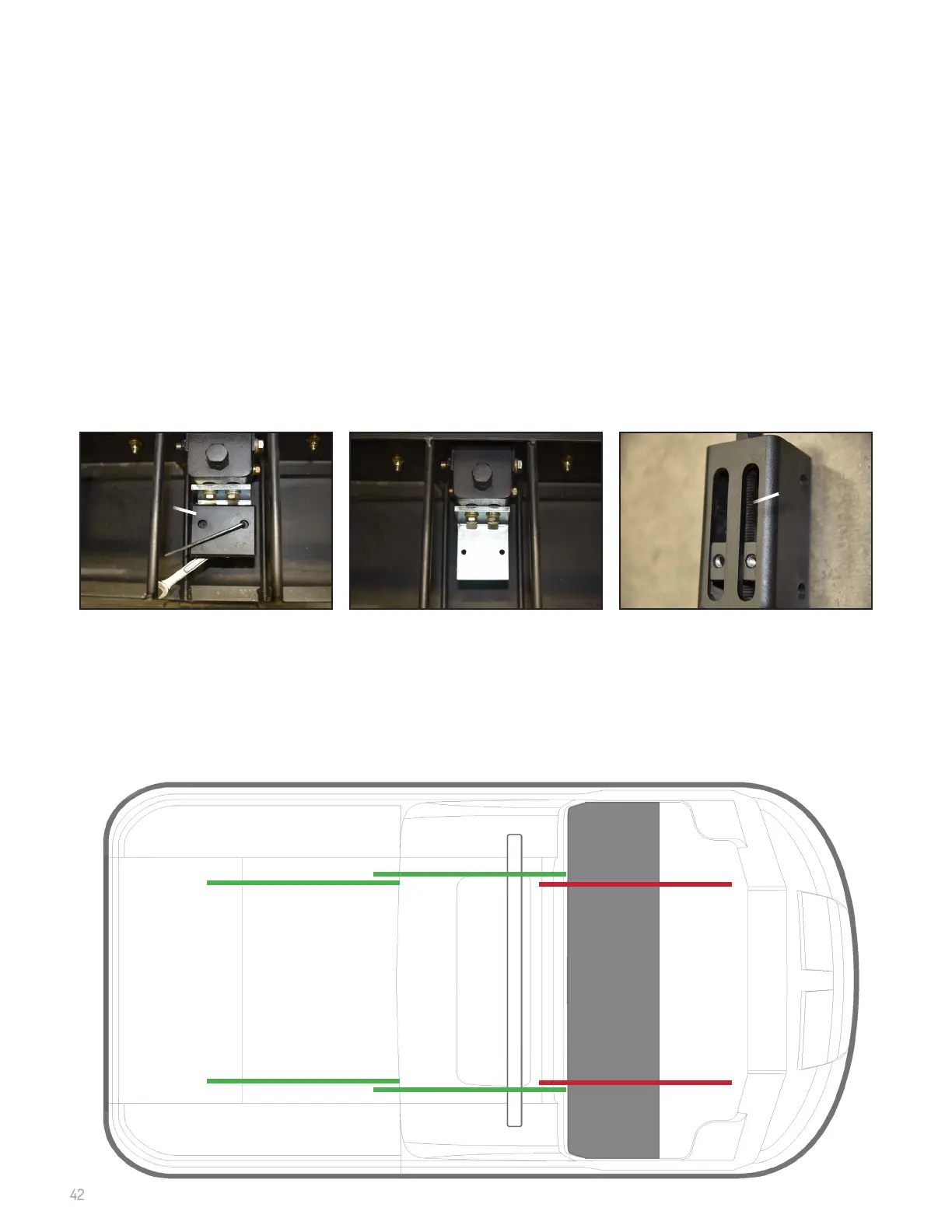

Locations

Chains: Shown as solid lines in Figure-6.

Chain tensioners: There are (2) different styles, notated by A and B in Figure-6.

A1A1

A2A2

B1B1

B2B2

B3B3

B4B4

Figure-6

Chains Cont.

Tensioner Style “B” InspectionTensioner Style “B” Inspection

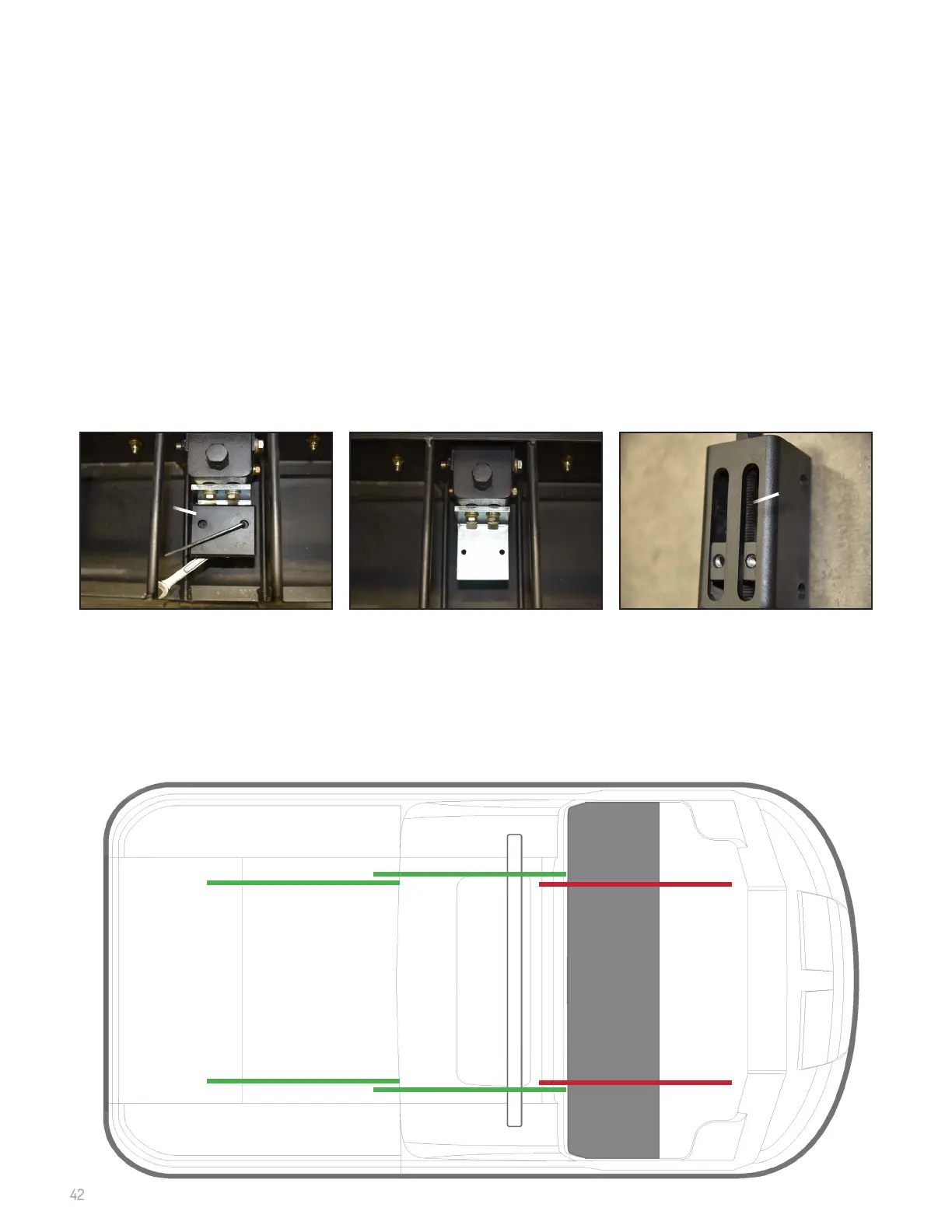

Plastic pad: The tensioner pad is made of plastic (A in Figure-3). As the chain moves across this pad, it will wear in a

pattern over time. A good tensioner pad should have at least 1/8” of material at its shallowest point. Bad pads may

be: broken in multiple pieces, worn down to metal, and/or a metallic noise is present while the vehicle is in motion.

If the pads are worn, simply use a 1/8” Allen and 7/16” wrench to remove the pads (Figure-4, 5). When installing

new pads, use new nyloc nuts and moderately tighten. Too tight will cause the Allen bolt to pull through the pad.

Note: It is possible to remove this pad with the chain on, but is easier when removed. Figure-4, 5 show the style

tensioner with chain removed.

Lubricating the tensioner: Inside the tensioner itself is a worm gear (B in Figure-5). This should be lubricated to

ensure smooth chain adjustment, and prevent seizing of the adjuster. Use sprayable white lithium grease to cover

the worm gear. If the worn gear is not visible, you must turn the adjusting nut until the L-shaped bracket is out of

the way. See Adjustment for instructions.

Figure-3

Bolt Removal

Figure-4

Pad Removed

Figure-5

Worm Gear

AA

BB

Loading...

Loading...