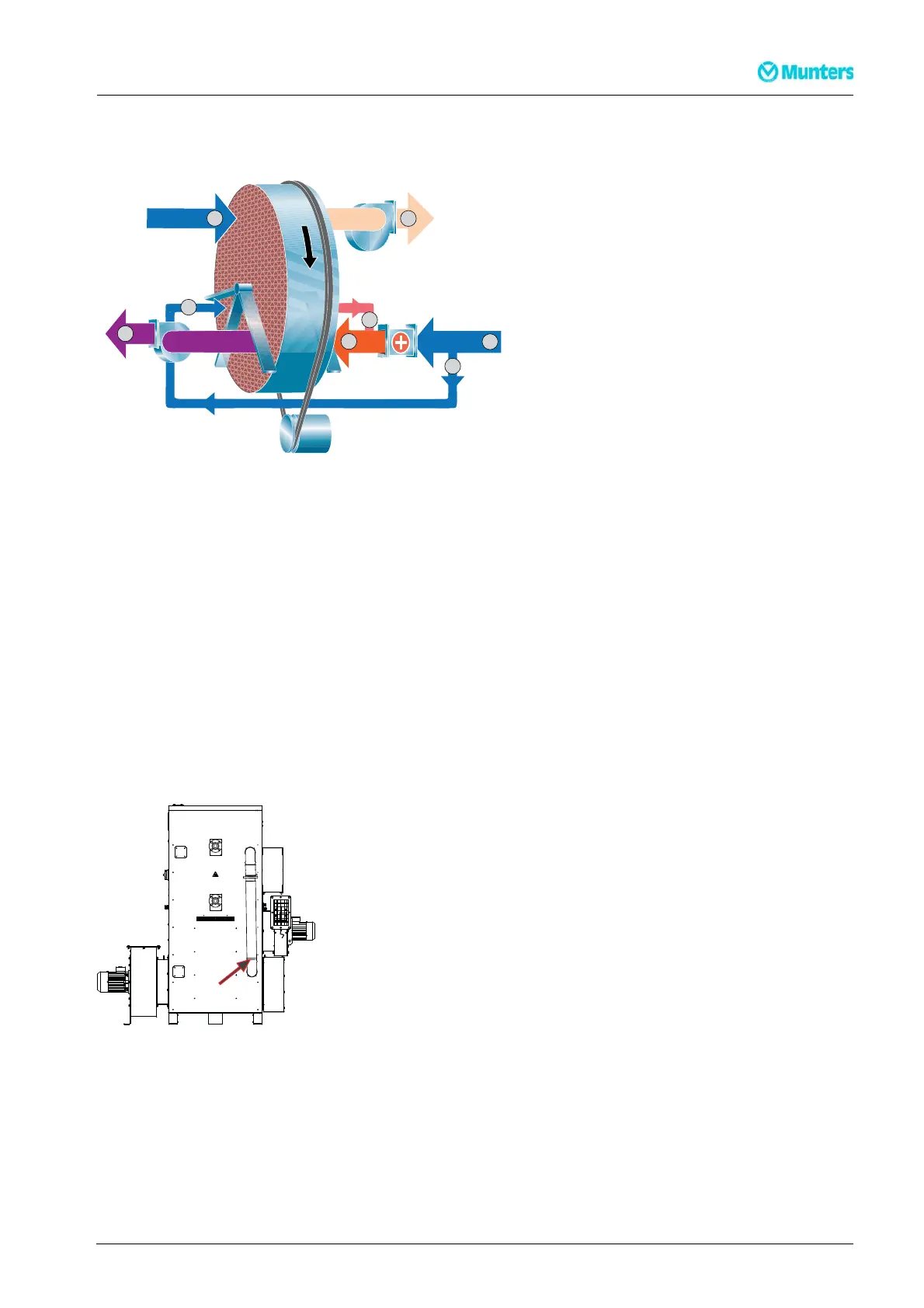

2.5.4 EnergyRecoveryPurgeandEnergyEfficiencyPurge

1

2

3

4

7

6

5

6

Figure 2.9 Principle for Energy Recovery Purge and Energy Efficien cy Purge

1. Reactivation air

2. Heated reactivation air

3. Wet air

4. Pr ocess air

5. Dry air

6. Purge air

7. Warm purge air

Energy Recover y Purge (ERP) and Energ y Efficiency Purge (EEP) are two energy saving solutions that

recycles heat f rom the rotor, after the reactivation section in the rotational direction of the rotor. A minor

part of the reactivation airflow is bypassed to the war m sector of the rotor, before the airflow enters the

reactivation heater. T he airflow is heated up by the rotor and then mixed with the reactivation airflow, after

the r eactivation heater. The recycled heat from the rotor increases the efficiency and reduces the energy

consumption.

Compared to a standard unit, ERP will give the same dehumidification capacity with reduced reactivation

heater energ y. With EEP, the reactivat ion heater energy is the same as in a standard unit, while the

dehumidification capacity is increased.

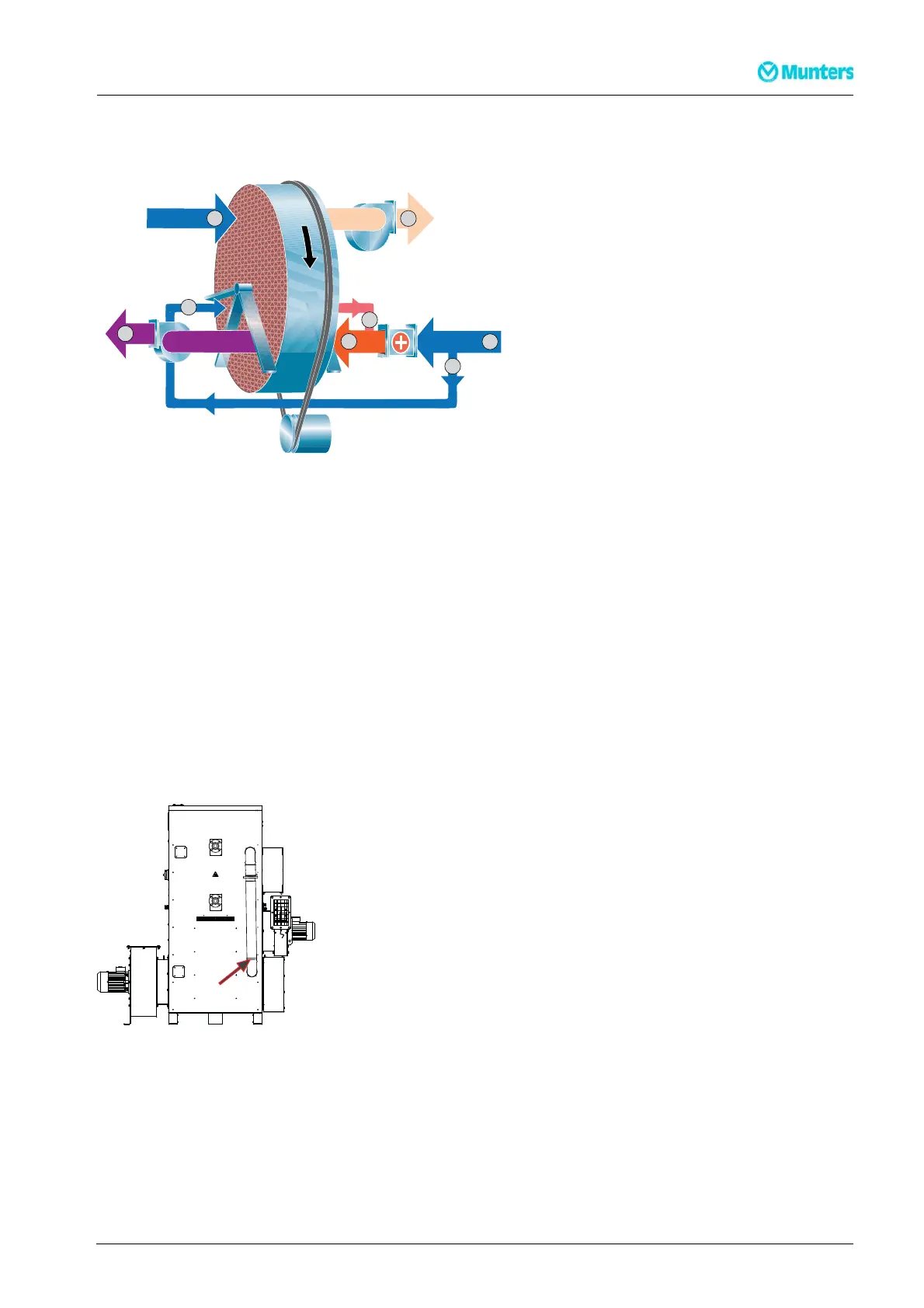

Thepurge airflow duct on MX² 30 is installed on the rear side of the unit. The purge airflow (ERP, EEP,

LDP)canbeadjustedwithadamperinstalledontheduct.

MX² 30

Figure 2.10 Purge airflow duct

Thepurge airflow duct on MX² 35–95 is located inside the unit and the purge airflow (ERP, EEP) cannot be

adjusted. An a djustable damper for Low Dewpoint Purge is located on top of the unit.

190TEN–108 9–G1412

Dehumidifierdesign

15

Loading...

Loading...