2205B0JE-DA-J-N_2014.05.

4 Compressor and Package Operation

Screw Compressor J-series 4.2 Lubricant (Refrigerant Oil)

4-2

4.2 Lubricant (Refrigerant Oil)

The selection and management of lubricant (refrigerant oil) has a significant influence to the

compressor performance

When selecting and managing lubricant, take the following points into consideration

4.2.1 Precautions for Selecting the Lubricant

The lubricant must be selected while considering the refrigerant in use, type of evaporator, and

operation conditions. Various properties of lubricant must be checked such as solubility with

the refrigerant, separability, fluidity at low temperature and thermal stability at high temperature

as well as viscosity. We therefore recommend consulting our sales offices or Mayekawa

agencies for choice of a specified brand for your system.

The lubricant supplied to the compressor must have appropriate proper viscosity to lubricate

bearings and other mechanical components. The lubricant viscosity must be measured at the

oil supply port of the compressor. The viscosity of lubricant is significantly affected by the type

of refrigerant and oil. If the refrigerant dissolves in oil (the oil is miscible), the actual viscosity

may be substantially lower than the required viscosity for the compressor depending on the

operation conditions. If the refrigerant does not dissolve in the oil (the oil is not miscible) and

the oil temperature is low, the viscosity may become excessively high. The lubricant must be

selected such that it is supplied to the compressor with appropriate viscosity (13 to 40 mm

2/

s)

in the operating conditions.

In a system utilizing a screw compressor, the lubricant supplied to the compressor is

discharged along with the gas and separated from the refrigerant gas by the oil separator.

However, the oil separator cannot separate all the oil from refrigerant gas and a small quantity

of the lubricant goes to the condenser. As a results oil also enters the evaporator. Because of

the wide operation temperature range of the lubricant, it must have thermal stability at high

temperatures, good fluidity at low temperatures as well as high separable performance from

refrigerant gas in the oil separator.

Depending on the refrigerant in use, some lubricants cannot be used. For example, polyolester

(POE) cannot be used with ammonia refrigerant.

4.2.2 Recommended Lubricant

When selecting lubricant, not only the refrigerant but also O-rings in use must be considered.

We therefore recommend using the following brands of lubricant for the J-series compressors to

prevent any operating problems.

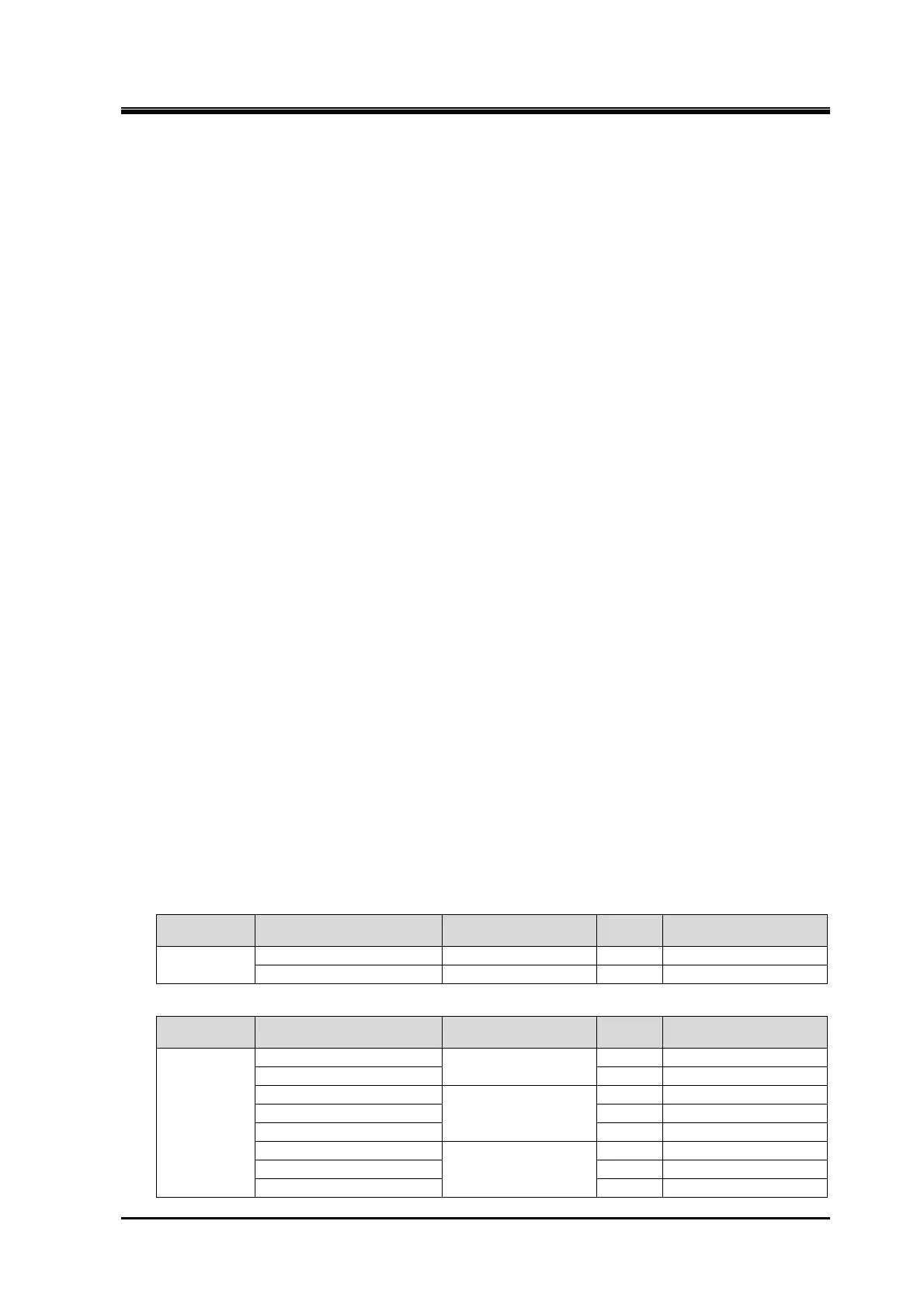

Recommended Lubricant for Ammonia Refrigerant

(1) Polyalkylene glycol synthetic oil (PAG): Miscible oil

Type Brand Manufacturer VG

Recommended

temperature

°C

PAG

Freol PN46 JX 46 40-50 see Note 1

RPS52 Kluber 46 40-50 see Note 1

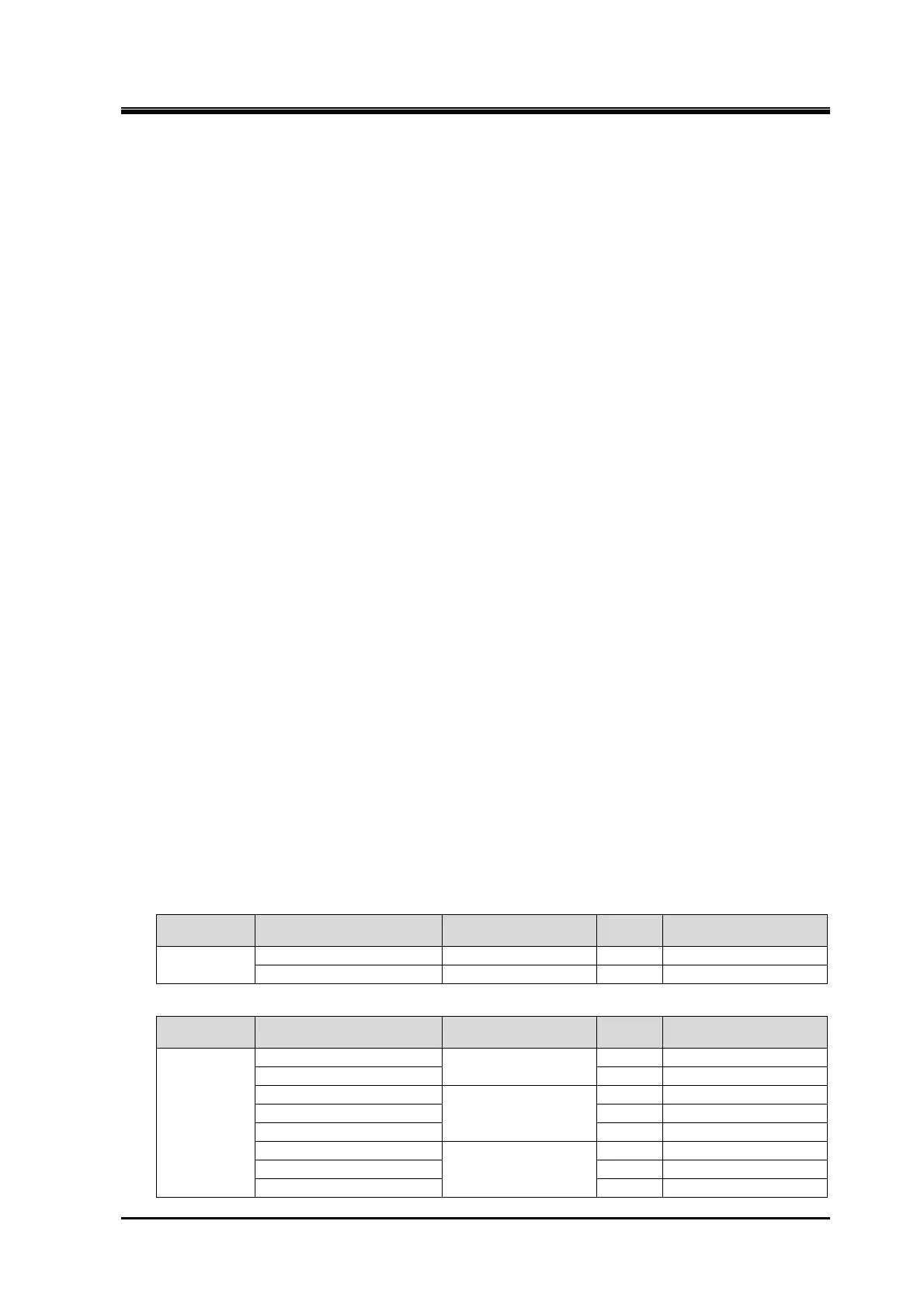

(2) Naphthenic base mineral oil: Non-miscible oil

Type Brand Manufacturer VG

Recommended

temperature

°C

M

Suniso 3GS

Sun Oil

32 35-60

Suniso 4GS 68 50-60

Gargoyle Arctic 155

Exxon Mobil

32 35-60

Gargoyle Arctic C Heavy 46 45-60

Gargoyle Arctic 300 68 55-60

Capella WF32

Texaco

32 35-60

Capella WF46 46 45-60

Capella WF68 68 55-60

Loading...

Loading...