2205B0JE-DA-J-N_2014.05.

5 Maintenance and Inspection

Screw Compressor J-series 5.4 Disassembly and Assembly of the Compressor

5-22

12. Remove the bottom four hexagon socket head cap screws (M16×60 for 170J, M16×75 for 220J,

M20×110 for 280J), which connect the main rotor casing with the bearing head, and the suction

cover.

Make sure that the lifting equipment and wires have sufficient load capacity for

the compressor. Otherwise, the compressor may fall, resulting in death or

injuries and damage to the compressor. Do not allow anyone to be under the

lifted compressor. (Compressor weight: 700 kg for 170JS, 730 kg for 170JM, 775

kgor 170JL, 1270 kg for 220JS, 1330 kg for 220JM, 1400 kg for 220JL, 2300 kg for

280JS, 2450 kg for 280JM, 2600 kg for 280JL)

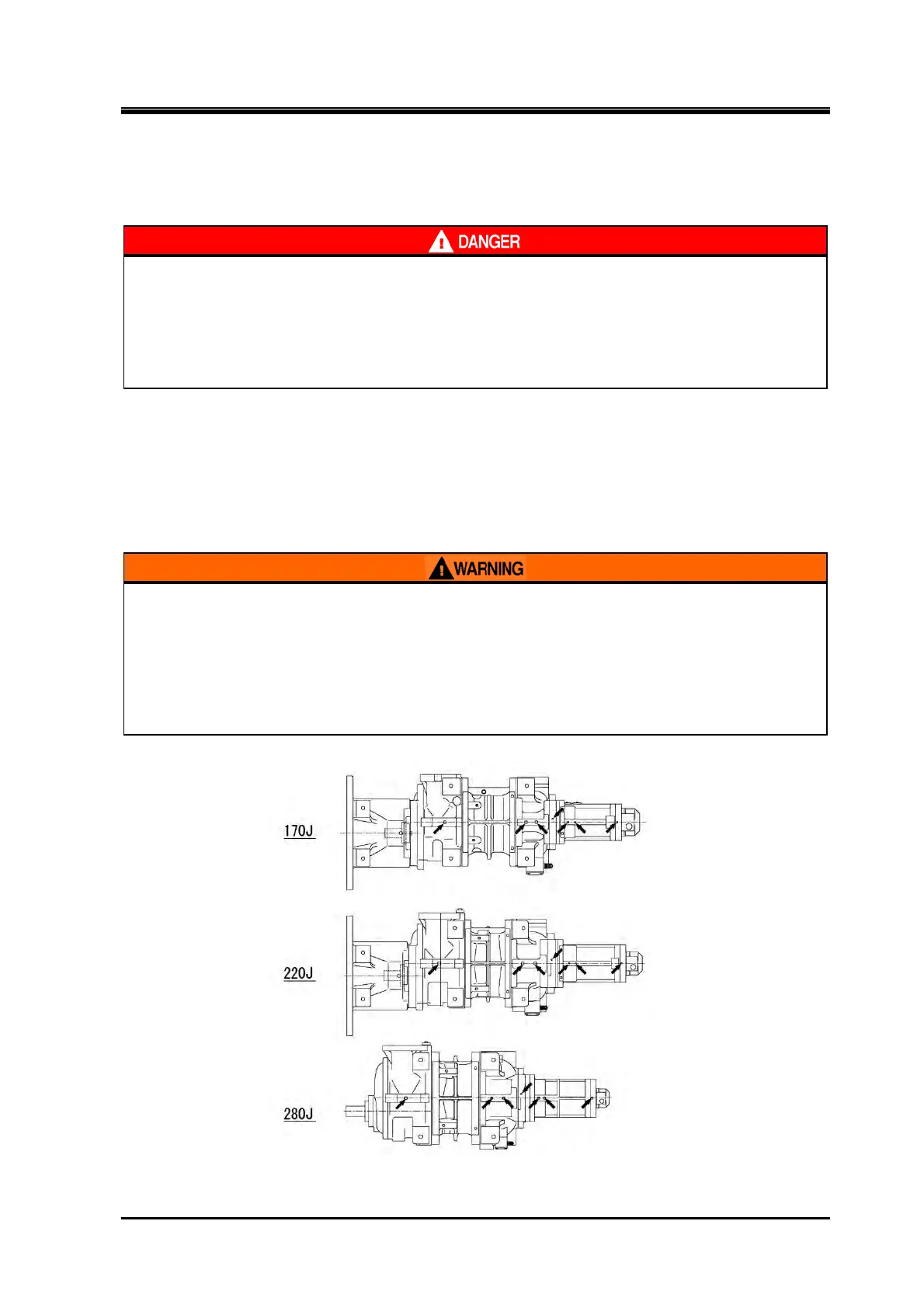

5.4.5 Removing Oil from Inside the Compressor

While placing the compressor on the work bench, remove the drain plug at the bottom of the

compressor as shown in the figure 5-2 and drain lubricant.

Make sure to reattach the removed plugs to the original positions (to prevent any plug being lef

detached).

If there is residual high-pressure gas/refrigerant or high-pressure oil dissolved in

refrigerant within the hydraulic cylinder (variable Vi cylinder and capacity control

cylinder), the refrigerant gas or oil may blow off when the oil drain plugs are

removed. This may result in injury such as frostbite and loss of vision. Therefore

always check and confirm the pressure in the hydraulic cylinder, before the oil

drain plugs are opened, and wear protective equipments such as goggles and

chemical resistant gloves.

Figure 5-2 Positions of Drain Plugs

Loading...

Loading...