2205B0JE-DA-J-N_2014.05.

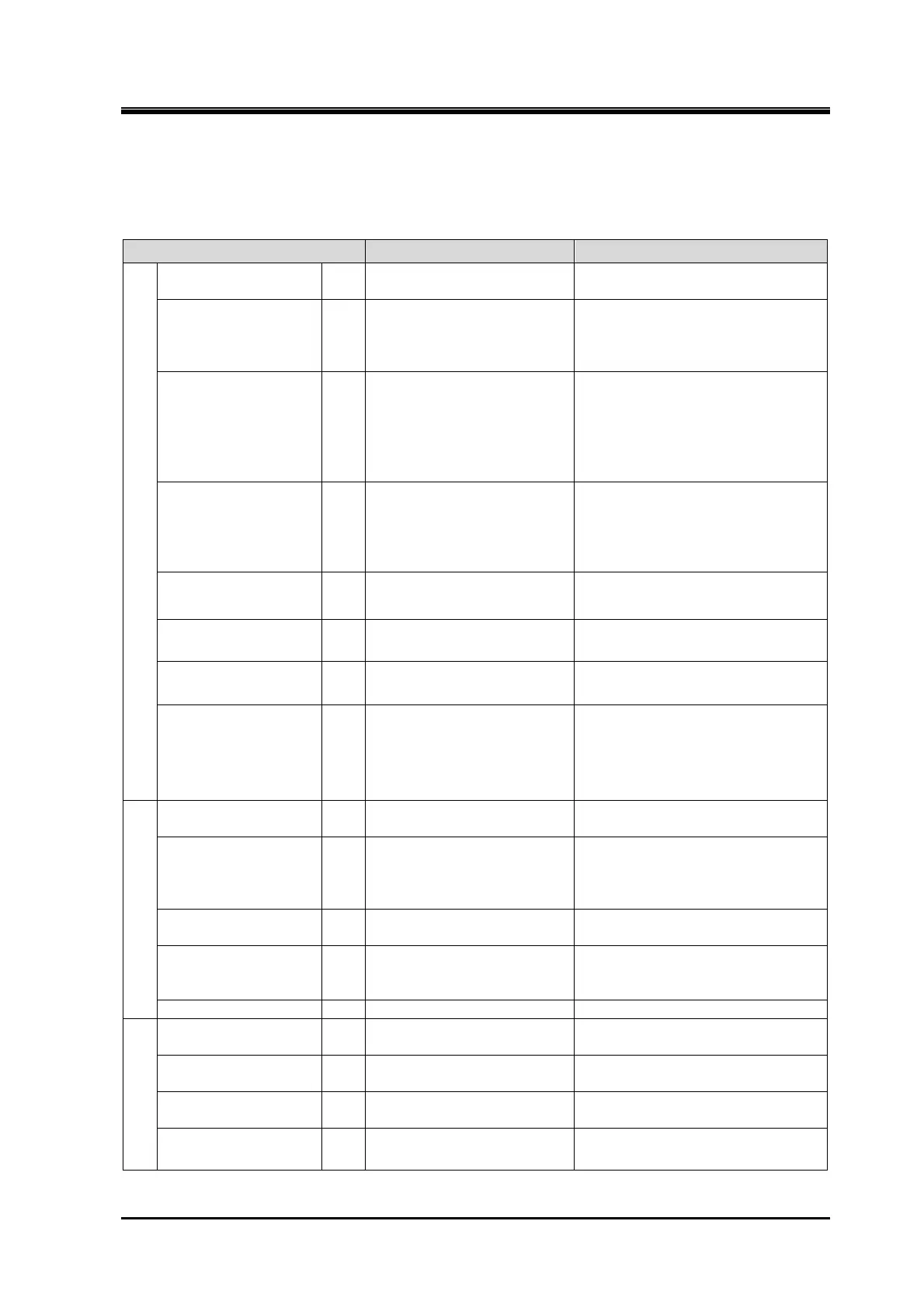

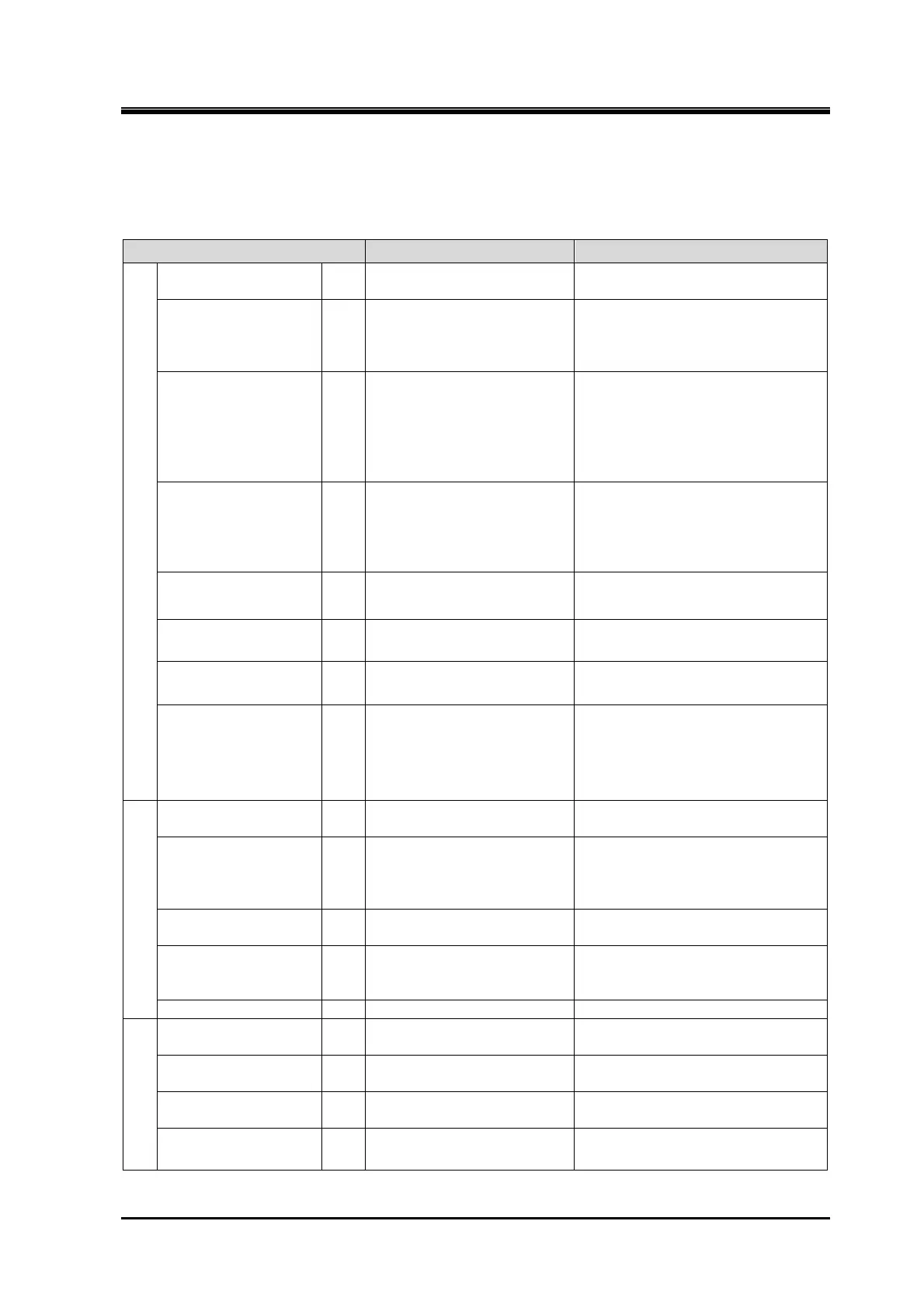

5 Maintenance and Inspection

Screw Compressor J-series 5.2 Maintenance List

5-3

Daily inspection items

Based on the operating log, check the following points.

Table 5-1 Daily Inspection Items

Inspection Items Inspection Contents Check Items/Actions

Compressor

Operating hours h Total operating hours Judgment of periodic

maintenance timing

Suction pressure

MPa

Note 1

Difference from the set value

of evaporation temperature

equivalent pressure

Contamination on the cooling

pipe surface

Temperature, flow rate, etc. of

the object to be cooled

Discharge pressure Mpa Difference from cooling water

temperature equivalent

condensing pressure

Contamination on condenser

cooling pipes

Non-condensable gases mixed

into the system

Quantity, temperature, etc. of

cooling water

Oil supply pressure MPa Difference from discharge

pressure

Whether differential pressure is

decreasing

Operation with liquid flow-back

Whether compressor parts are

worn

Oil filter pressure loss MPa Pressure difference between

oil filter inlet and outlet

Contamination of lubricant

Clogging of oil filter

Suction temperature °C Whether within upper and

lower limits

Temperature, flow rate, etc. of

the object to be cooled

Degree of superheat

for suction

°C Whether degree of

superheat is proper

Adjust expansion valve

Insufficient refrigerant flow

Discharge

temperature

°C Whether within upper limit Non-condensable gases mixed

into the system

Oil supply temperature,

insufficient oil supply

Compressor failure

Oil supply

temperature

°C Whether within upper and

lower limits

Contamination on cooling pipes

of oil cooler

Capacity control

Indicated load

%

Whether operation is normal Damage to solenoid valve coil

Improper adjustment of manual

control valve of electromagnetic

assembly

Leak from mechanical

seal

mL/h

Leak per hour Mechanical seal failure

Variable Vi valve

position (L, M, H)

Whether port position is

appropriate for operating

conditions

Damaged solenoid valve coil

Position sensor failure

Noise and vibration Abnormal noise/vibration Compressor failure

Others

Motor current A Whether it is higher than the

current at test run

Compressor failure

Motor failure

Oil level of oil

separator

- Oil level Oil loss

Replenish oil

Fluid level in the

receiver

- Fluid level Replenish refrigerant

Check for refrigerant

leak

-

leak or not The machine room and the load

side facilities

Note 1 : Unless otherwise noted, the pressure unit MPa represents the gauge pressure in this manual.

Compressor

Loading...

Loading...