REFRIGERATION DIVISION

V SERIES

SCREW COMPRESSOR HANDLING MANUAL

Supersedes all previous version. This information is for reference use only and subject to change without notice

Revision 2 (June 05,2000) Page 44 of 61

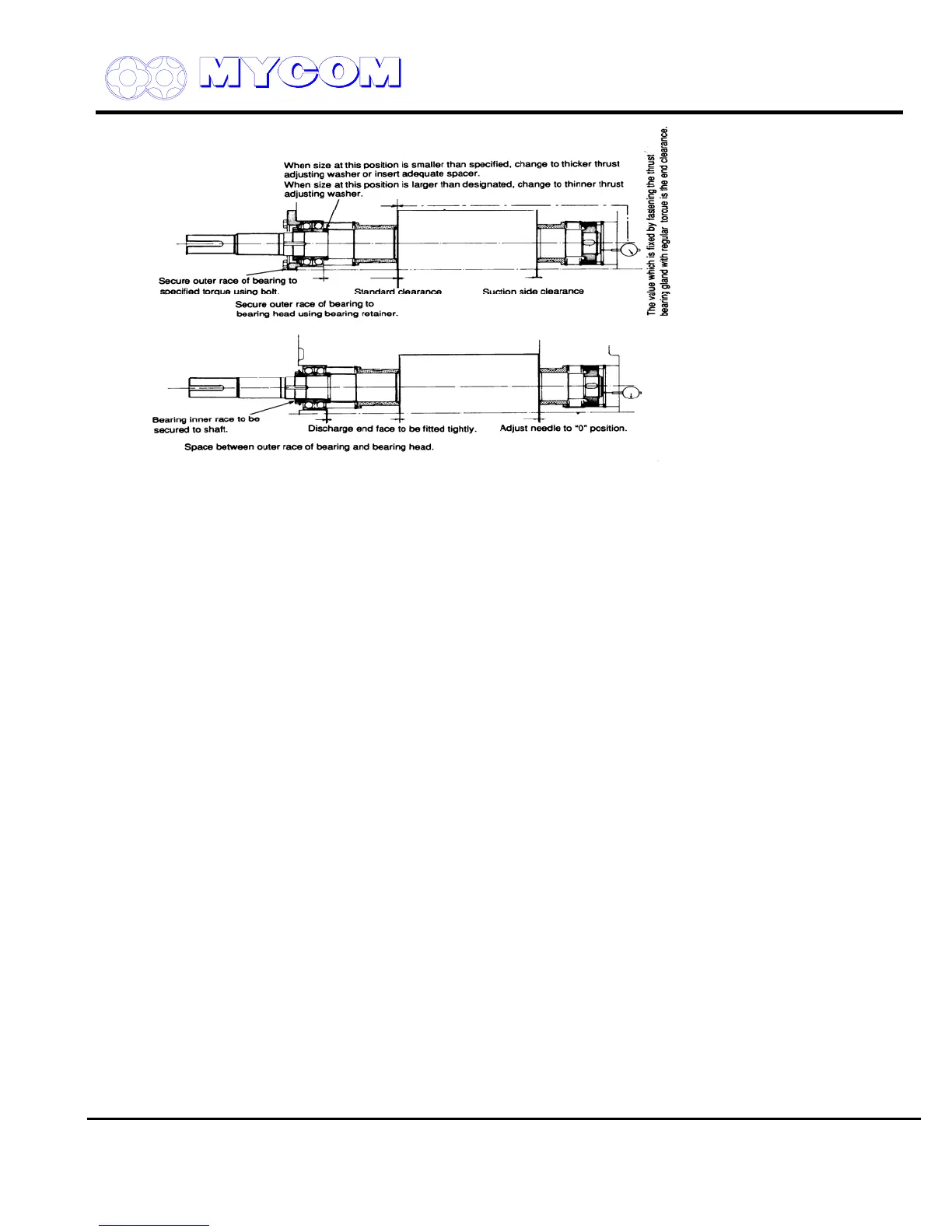

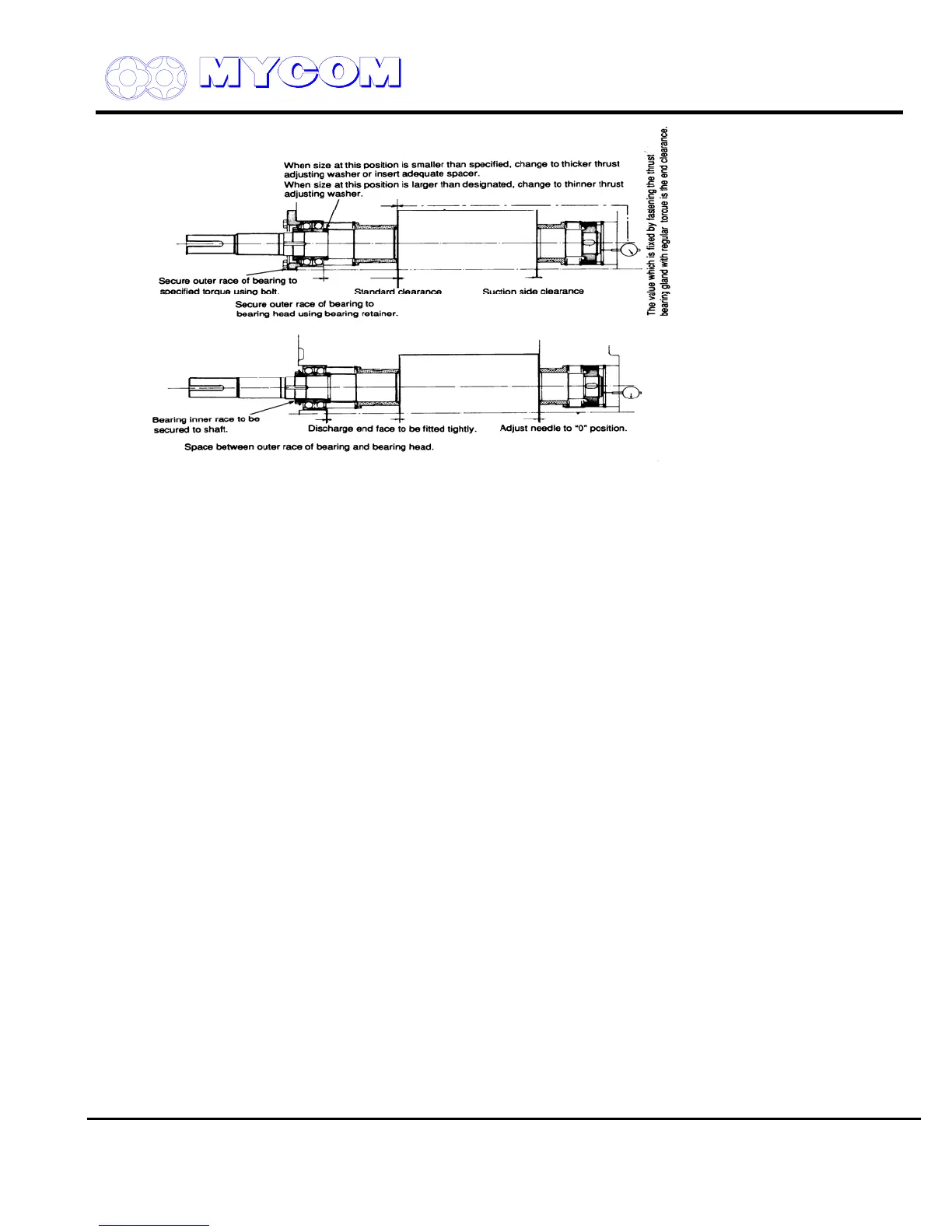

Fig. 90B Adjusting End Clearance

i. First method:

Since the dimension at “A” shown in Fig. 90B is too large because the thrust adjusting washer

is too thick, the face of the washer must be ground down by the amount of the difference

between the measured value and the specified value.

To accomplish this, a high precision surface grind must be used to ensure that both sides of

the washer are parallel. After machining, measure the thickness around the entire

circumference of the washer using a micrometer.

This method can be used for all models.

ii. Second Method

Insert a shim of the required thickness between the bearing gland (41) and the outer race of

the bearing. The thickness of the shim is determined by the difference between the measured

value and the specified value.

A shim of brass or copper should not be used if the system refrigerant is ammonia because

these materials are easily corroded by the gas. An iron shim should be used instead.

2) When the end clearance is smaller than the specified value.

In this case, the rotor will not rotate when the lock nuts are tightened. The reason is that the

thrust adjusting washer (42) is not thick enough or the bearing gland (41) is too thick.

Accordingly, a shim of the required thickness must be inserted between the thrust adjusting

washer and the inner race of the thrust bearing. Using a new thrust adjusting washer with the

correct thickness is much better than adjusting the thickness with shims.

If the gland is too thick, it should be ground to the necessary dimensions (since no gland is

proved on the 250V** and larger compressor models, adjustment must be accomplished with

the adjusting washer (42)).

After adjusting the clearance, measure several times and confirm that the proper end

clearance is achieved.

k) Rotate the male rotor manually to confirm smooth rotation.

Loading...

Loading...