16 of 53

GT1175 (H105 Medium) Hurricane Quick Set-Up and Parts Guide www.NabcoEntrances.com

P/N C-00106 Rev 8-10-16

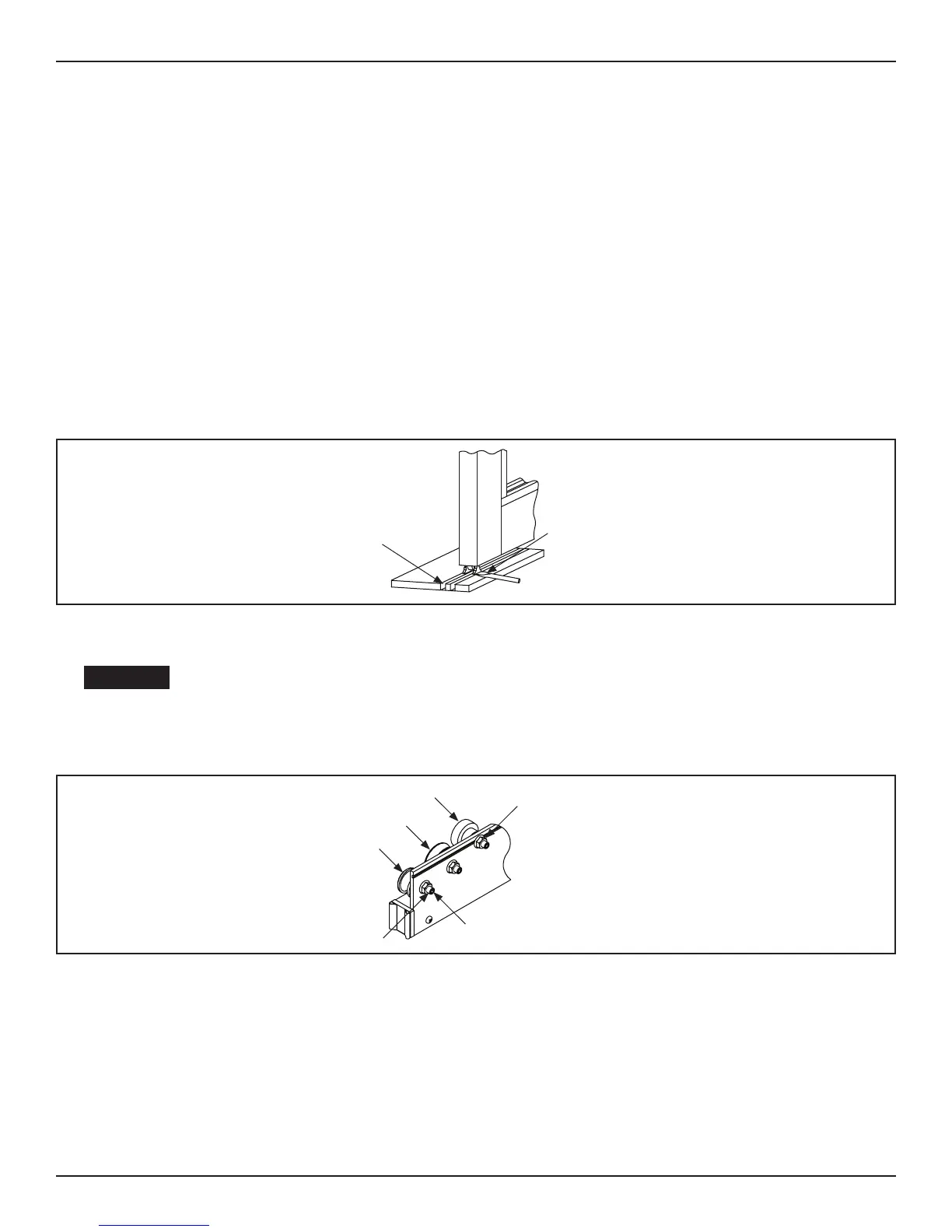

2. Slide the door onto the Bracket poron of the Double Roller Assembly.

3. Breakout the Slide door to Full Open posion.

a. Support the weight of the Slide door.

4. Line up Bracket screw holes to the (2) pre-drilled screw holes located on Boom Rail.

5. Secure Bracket to the Boom Rail with (2) #10-31 x .50 Phillips Head screws.

FOR FIXED SIDELITE UNITS SKIP TO

SUBSECTION 6.5

1. Go to Boom Rail of the Slide door.

2. Locate the Boom Guide Assembly that was preinstalled inside the Strike Sle.

3. Li up the Prongs unl the Boom Guide is directly above the Guide Channels.

4. Allow the Prongs to drop down into the Guide Channels.

5. Obtain screws and anchors per NOA Documentaon.

a. NABCO does not supply screws and anchors to secure the Floor Track.

b. The number of screws and anchors depends upon length of Floor Track.

6. Permanently secure the Floor Track with scews and anchors.

Figure 27 Drop Prongs into Channel Guides

DN 0894

Li Up

Bo om Guide; Prongs

Guide Channels

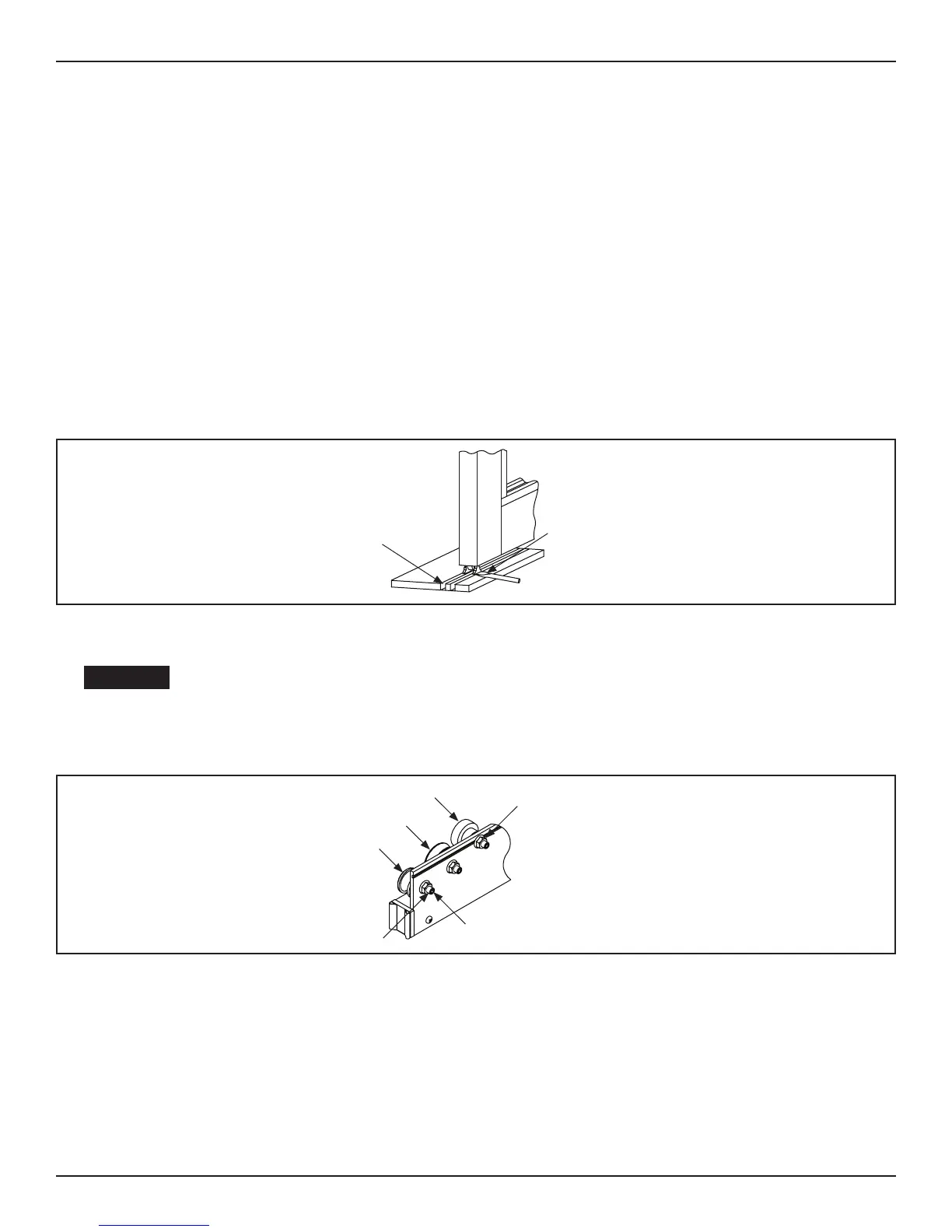

Do Not rotate the Roller Axle counter-clockwise. Doing so will unthread the Axle from the

Roller assembly.

1. To loosen a Roller, insert a 7/32” Allen wrench into the exposed end of a Roller Axle.

2. Hold the 7/32” Allen wrench in place to keep the Roller Axle staonary. At the same me, loosen (1) 7/16-20 Whizlock nut

with a 15/16” Open End Wrench.

DN 0897

Hanger Roller

An -Rise Roller

Eccentric Retainer Roller

End of Roller Axle

7/16-20 Whizlock Nut

Axle

Figure 28 Loosen Carrier Rollers

Hanger Rollers are used to:

► Evenly distribute weight of the Slide door.

► Adjust height of the Slide door.

►

1. Loosen (2) Hanger Rollers located between the An-Rise Roller and the Eccentric Carrier Roller.

2. Raise or lower the Slide door by turning the Axle clockwise with a 15/16” Open End Wrench.

a. The appropriate gap between the Boom Rail and oor is between 11/16 inch to 15/16 inch; with the nominal gap

being 7/8 inch.

Loading...

Loading...