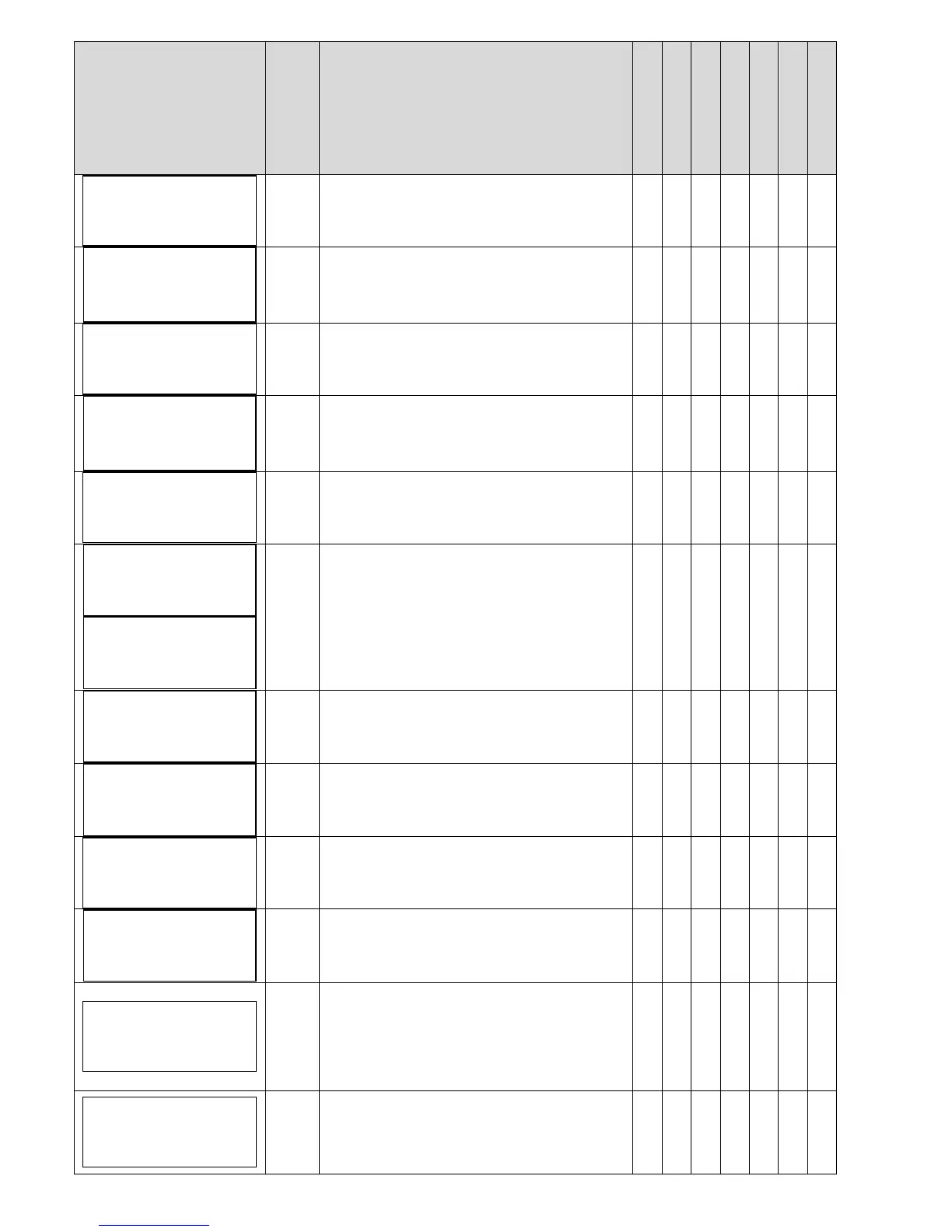

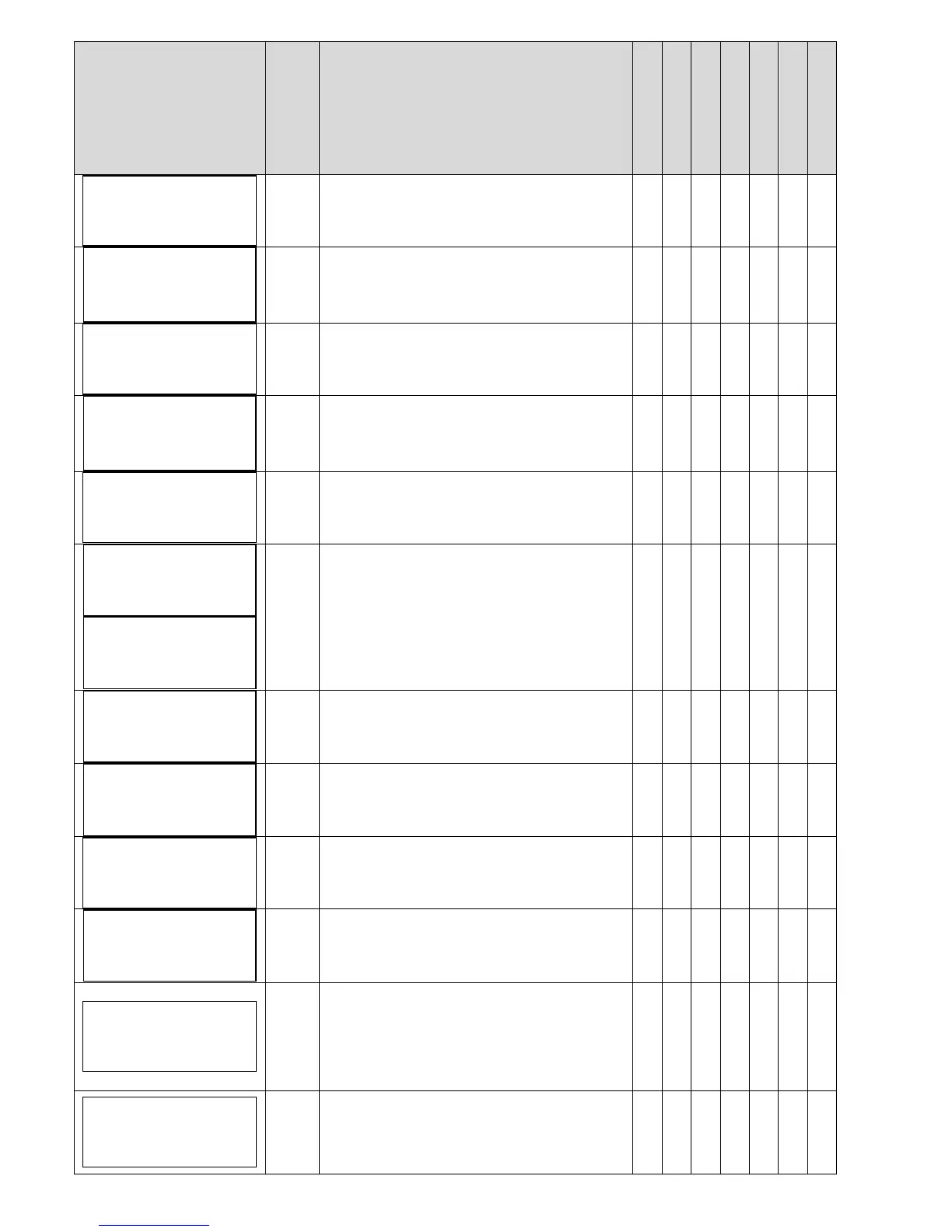

It's the increase of pressure respect to pressure

set which must be passed so that there is a forced

shutdown of the pump.

The common parameters than you should get the

temperature above the temperature set so that

the pump, arrested earlier, are restarted.

It's the temperature rise compared to

temperature set which must be passed so that

there is a forced shutdown of the pump.

This value represents the flow drop below the set

flow required to start the pump.

It's the increase of flow respect to flow set which

must be passed so that there is a forced

shutdown of the pump.

Kp and Ki parameters allow the dynamic control

of system by VASCO; set values (Ki=50, Kp=005)

are usually enough to get a valid dynamic control;

if the set pressure do not consent a valid control,

proceed as follows; increase or reduce Ki while

keeping Kp constant; if the problem persists,

increase Kp value and increase or reduce the Ki

value again till a good dynamic control is reached.

Function to activate (ON) the first auxiliary pump

DOL 1 (Direct On Line pump).

Function to activate (ON) the second auxiliary

pump DOL 2 (Direct On Line pump).

Function to allow alternating starting priority

between the DOL pumps in order to allow equal

use of them.

delay time with which the pumps DOL start after

the variable speed pump has reached the

maximum frequency and the pressure value has

fallen below set pressure – delta start pressure

Function to enable multiple VASCO’s to work in

parallel as described in the technical appendix

(see the relevant chapter). Up to 8 VASCO units

can be connected in parallel.

VASCO’s communication through RS 485 gates is

granted by a private protocol.

Direct: increasing misured pressure, VASCO

decreases motor frequency.

Inverse: increasing misured pressure, VASCO

increase motor frequency.

PI control

Direct/Reverse

Start delay AUX

t = XX [s]

Delta stop flow

Q = XXX.X [m3/h]

Delta start flow

Q = XXX.X [m3/h]

Delta stop temp.

T = XXX.X [°C]

Delta start temp.

T = XXX.X [°C]

Delta stop press

p = XX.X [bar]

Loading...

Loading...