If two pumps are connected in parallel, the first driven by VASCO and the second with a DOL

connection, it is necessary makes sure that the value “delta pressure restart” will be sufficiently high

to ensure the first pump, once the DOL pump is switched on, will reach a frequency higher than its

minimum frequency value.

By proper setting of the minimum frequency, excessive pump ON/OFF cycling is avoided, thus

preventing damage to the DOL pump.

9.2 COMBO function

In the “Installer parameters” menu it is possible to enable the COMBO function that allows serial communication between up

to 8 VASCOs, each one connected to a pump. The operating principle (switch on/off) of pumps is similar to as stated in

chapter 9.1.

To achieve the COMBO function in a system consisting of several interconnected VASCOs, use a pressure sensor connected

to each VASCO. The value of the set pressure is communicated to the slaves via the serial port.

To prevent the shutdown of the system due to pressure sensor failure, connecting a 2nd pressure sensor to the VASCO;

make sure that the two pressure sensors are identical.

Remember to perform the offset operation of the sensors in each VASCO (Installer Parameters menu) .

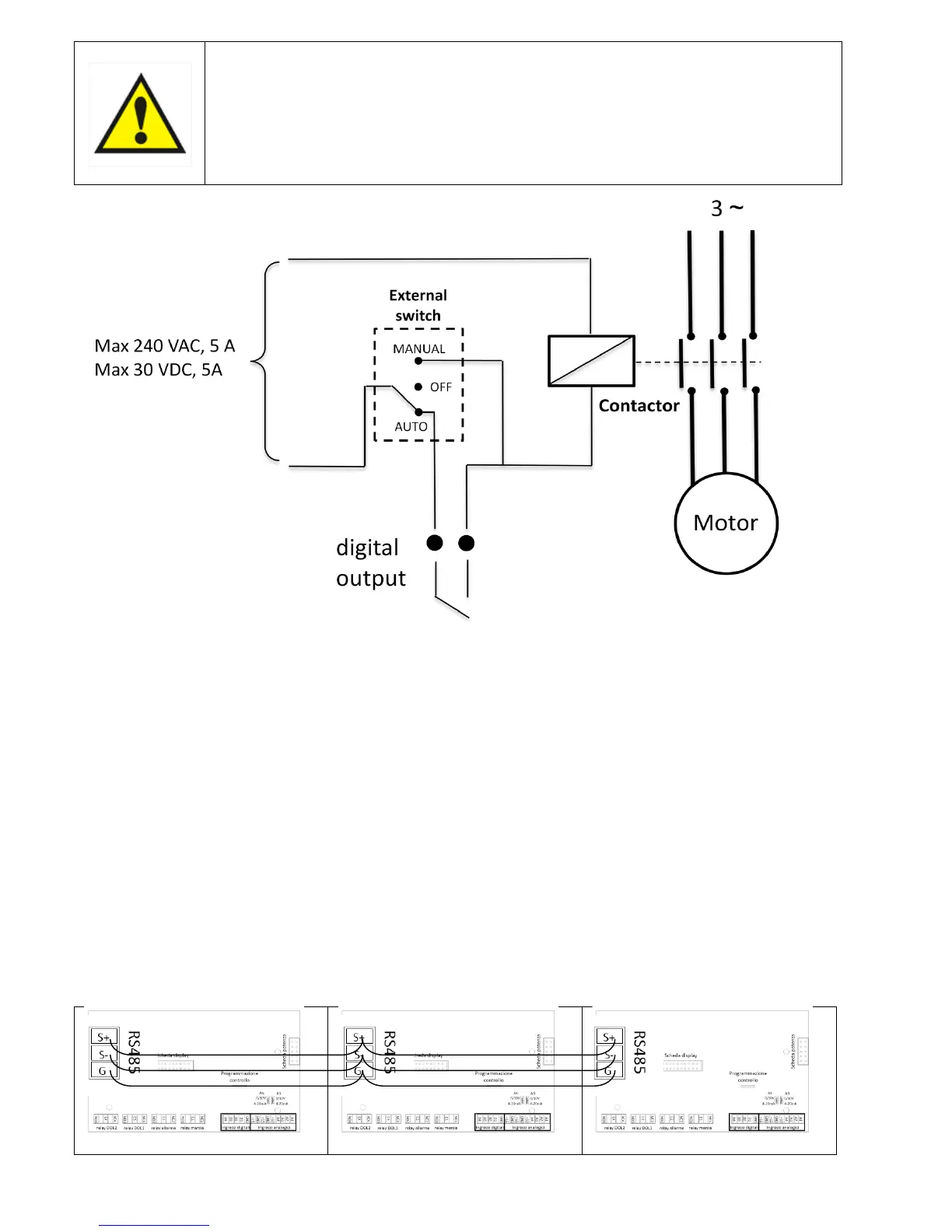

As a further help, you can connect another two DOL pumps to the VASCO Master to cover additional water demand; they

will be operated only when all the COMBO pumps are already in operation.

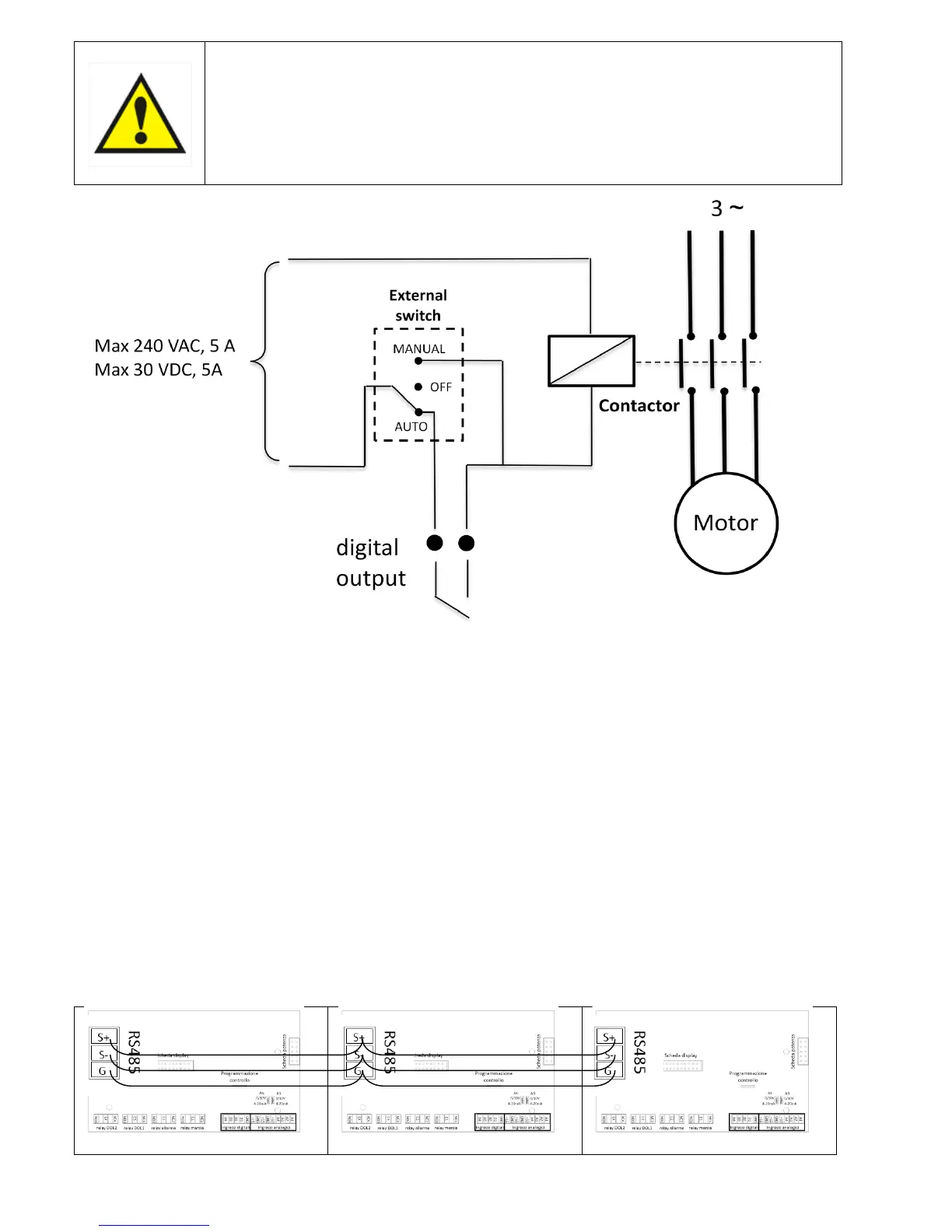

RS485 serial connection

VASCO’s communication is made through a private protocol using the RS485 port. Each VASCO must be connected to each

other by using a tripolar cable (0,5 mm

2

) wired on S+,S-,G pins on control board.

Loading...

Loading...