101Appendixes

c. Activate multiple zones and set the boiler to operate at

1-stage MIN mode (refer to “11.4.7 Setting the Special

Operation Modes” on page 95). Measure the offset value

at low fire and compare it to the values in Table 3. If the

offset value is out of range, the gas valve set screw will

need to be adjusted.

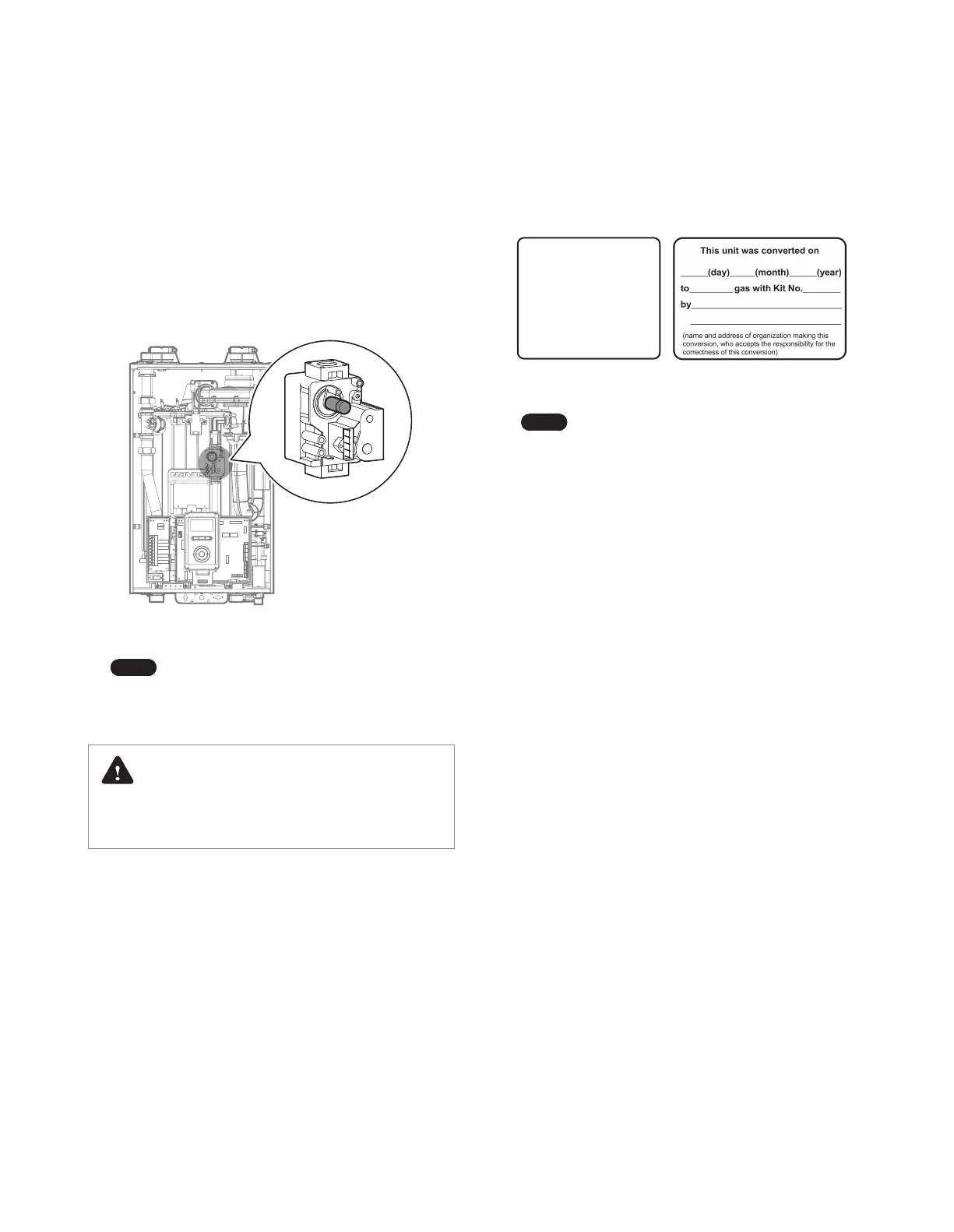

If adjustment is necessary, locate the set screw as shown

in Figure 10. Using a

5

/

32

in or 4mm Allen wrench, turn

the set screw no more than

1

/

4

turn clockwise to raise or

counterclockwise to lower the offset value.

Figure 10. Set Screw Location

Note

The set screw is located behind the screw-on cover.

This must be removed first.

d. At high fire, do not check the offset value and never adjust

the gas valve.

DANGER

Improper gas valve settings can cause severe personal injury,

death or substantial property damage.

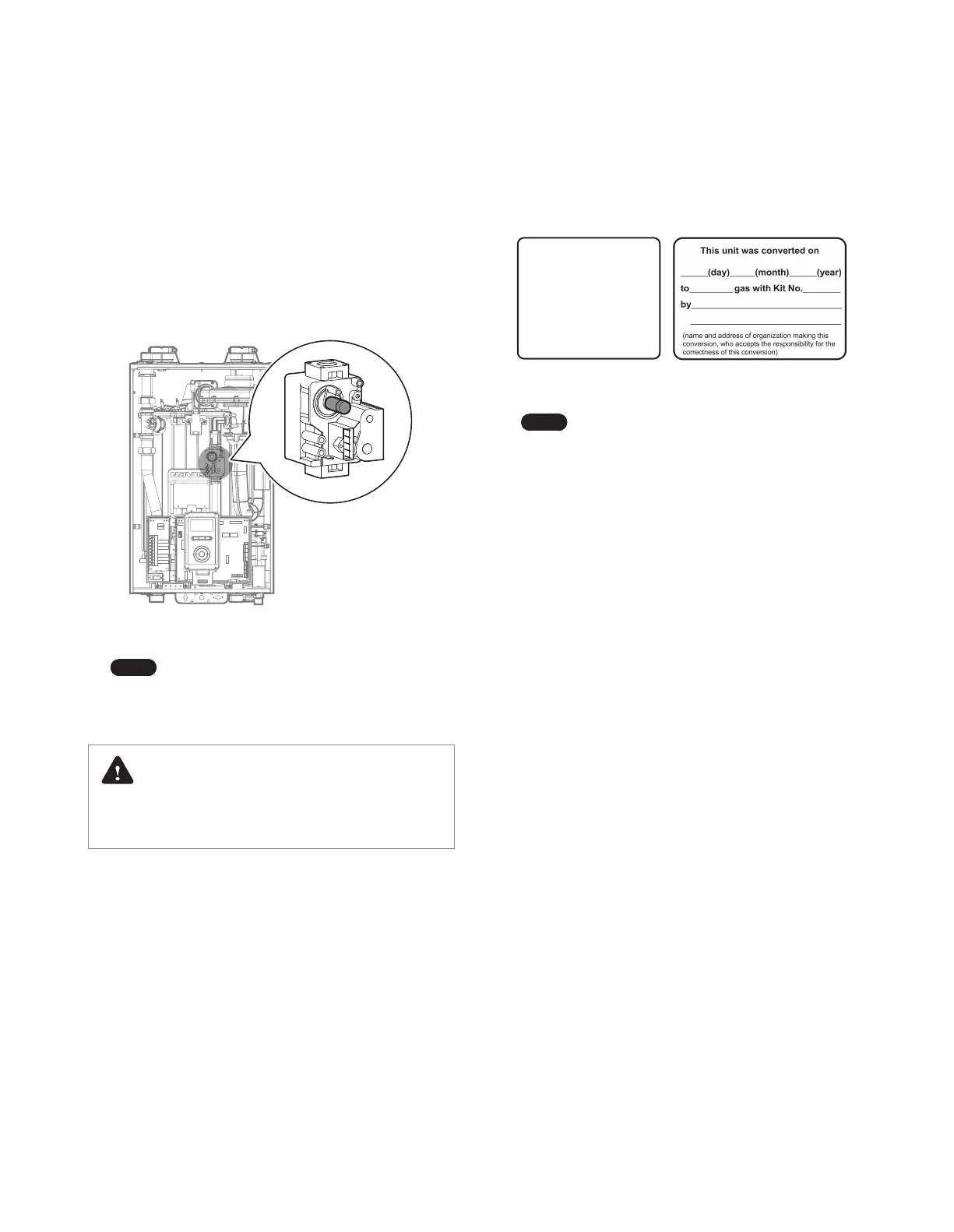

13. Once the CO

2

or offset values have been confirmed, apply the

included conversion stickers to show that the appliance has

been converted to propane gas. Place these labels adjacent to

the rating plate as shown in Figure 11.

Orice Size / Injecteur:

Min. 4.5 mm to Max. 4.9 mm

This unit has been

converted to Propane fuel

Cet appareil a ete converti au Propane

Manifold Gas Pressure /

Pression à la tubulure d’alimentation:

Min. -0.10 to Max. -0.45 in WC

BTU Input / Debit calorique:

Max. 199,900 - Min. 19,900 BTUh

Conversion Kit No.: NAC-L200

Inlet Gas Pressure / Pression d'entrée du gaz:

Min. 8.0 to Max. 13.0 in

Figure 11. Proper Placement of Gas Conversion Labels

Note

The gas conversion rating plate varies depending

on the model. Check the conversion kit number

before attaching the labels.

Loading...

Loading...