Nedap SmartFlow / Installation manual

Version 01.001 / 2021 / EN

27

Dairy Farming

4 Configuration

Caution

When the milking process in the milking parlor is controlled by Nedap Milking Point Control Units (MPCUs),

the MPCUs must be configured before the SmartFlow milkmeters are configured (see the MPCU Installation

Manual).

Configuration procedure

Configure the SmartFlow system in the following order to ensure a correct start-up:

1. Configure the VP8002 VPU and VP4102 reader (page 27).

2. Configure the Velos software (page 28)

3. Zero Point test of the SmartFlow Floats (see Zero Point test (page 28)).

4. Calibration of the SmartFlow milk meters (Calibrate the SmartFlow (page 30).

Calibration and validation procedures for the

SmartFlow milk meters

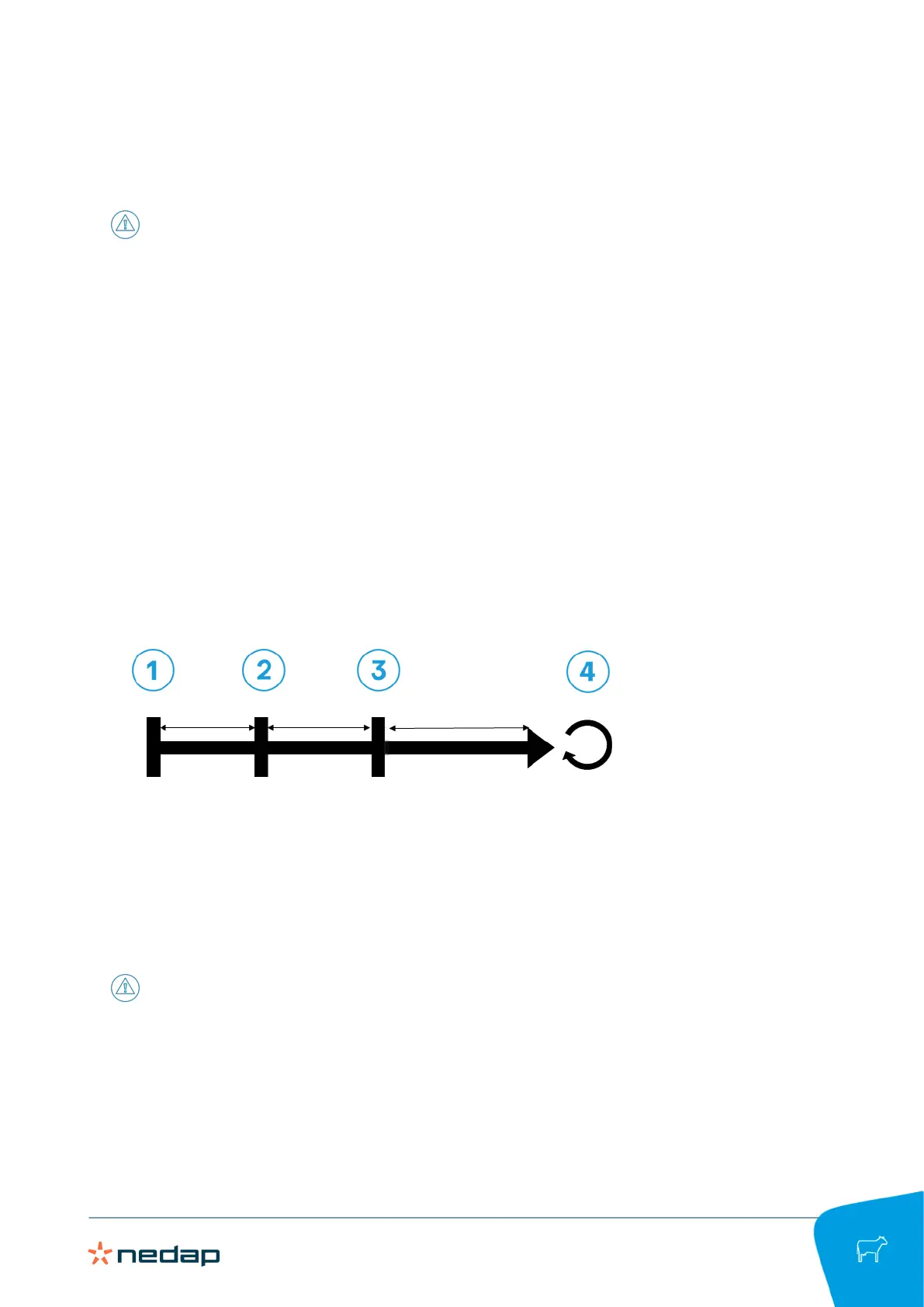

An overview of the SmartFlow calibration and validation moments is shown below:

1. Installation of the new milking parlor, including the SmartFlow milk meters.

2. Zero Point test of the SmartFlows to determine the setpoint of the Float (see Zero Point test (page 28)).

3. Calibration of the SmartFlows by carrying out the auto calibration or milk test (see Calibrate the SmartFlow

(page 30)).

4. Annual validation check of the SmartFlows by checking either the Zero Point test or the correction factors

(see Routine checks (page 34)).

Caution

When a component of the SmartFlow is repaired or replaced, for instance the Float, the SmartFlow needs to

be calibrated and validated again by executing step 2, 3 and 4.

4.1 Configure the VP8002 VPU and VP4102

reader

Configure the VP8002 VPU(s) and VP4102 reader(s) before the SmartFlow milk meters are configured.

Loading...

Loading...